Developing a Forging Solution

After receiving customer drawings, we develop customized forging solutions based on product shape, tolerances, materials, and application scenarios to maximize mold life and production efficiency.

Make the Mold

Relying on our in-house mold R&D team, we utilize high-precision CNC machining equipment to transform design schemes into physical steel molds. This allows us to meet customer customization needs in the shortest possible time, laying a solid foundation for subsequent high-precision, high-quality forging operations.

Make Samples

Before mass production, we conduct a rigorous first-piece trial production according to technical requirements. Comprehensive testing verifies mold precision, material flow, and part shape to ensure the finished product's physical parameters fully meet design standards before initiating large-scale production.

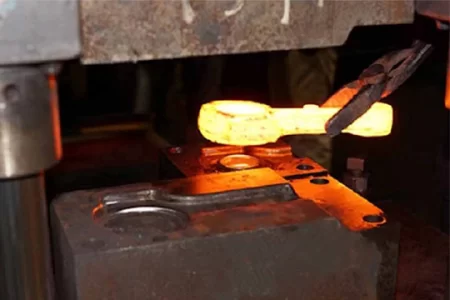

Mass Production

Utilizing advanced 200-1000 ton presses for precision hot forging, operated by experienced technicians with an average of over 10 years of experience, we can stably produce high-standard forgings ranging from 0.5kg to 50kg, ensuring high consistency in quality across each batch.

Heat Treatment

To meet the specific performance requirements of precision forgings, processes such as normalizing, quenching, or tempering are used to precisely control the internal structure of the metal, effectively improving the tensile strength, toughness, and mechanical stability of the parts, enabling them to meet the stringent performance challenges of various industrial fields.

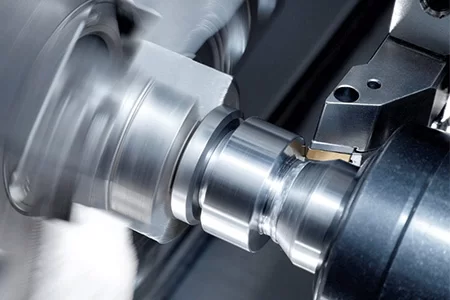

CNC Machining

HULK Metal is equipped with professional machining centers to perform precision CNC machining on forging blanks. Advanced cutting and drilling processes ensure that the dimensional tolerances of key parts meet accuracy requirements and that high standards of surface flatness are achieved.

Packaging

Based on a complete supply chain management system, and according to product characteristics and transportation distance, we tailor professional rust-proof and shock-proof packaging solutions to ensure that precision forging parts are protected from corrosion and collision during long-distance logistics, delivering them to customers in perfect condition.

Delivery

We provide one-stop freight consultation and warehousing logistics services. Relying on a mature supply chain network, we select the optimal transportation solution based on customers' delivery cycle needs, monitor the status of goods in real time, and ensure that global customers enjoy efficient and timely product delivery services.

After-sales Service

We adhere to the values of "win-win and pragmatism," have established a comprehensive feedback loop system, and have experienced quality inspectors provide technical support to quickly respond to customer inquiries and handle potential problems, comprehensively protecting the project operation and long-term rights of our customers.