We have advanced equipment and rich experience, focusing on providing high-quality hot forging production services. The use of advanced process technology ensures stable and reliable product quality.

Custom Forged Manufacturer

HULK Metal Hot Forging Factory

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

As a leading domestic forging manufacturer, we focus on providing customers with personalized and customized first-class forging services. Drawing on our many years of precision machining experience, we are committed to creating forged components with the highest level of precision and quality for you. Whether your needs are custom design, superior strength or tight tolerance requirements, we have the skilled team to meet your every need.

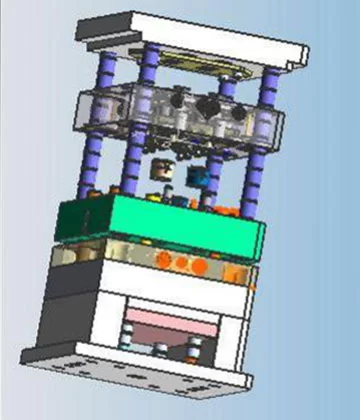

HOT FORGING FACTORY PRODUCTION LINE

HULK Metal has die forging production lines based on 1000T hot die forging press, 630T hot die forging press, 400T hot die forging press, and 200T hot die forging press, which can process products from 0.5kg to 50kg.If you have any needs, please feel free to contact us immediately!

-

011000T hot forging frame press

The 1000T hot forging frame press can complete the basic process of forging products.

-

02630T hot forging frame press

Forgings forged using the 630T press have high precision, high material utilization, high productivity, and are easy to automate.

-

03400T hot forging frame press

The control of the 400-ton hot forging press adopts a cartridge valve integrated system, which has small impact, reliable action and few leakage points.

-

04200T hot forging frame press

00T hot forging frame press is used to simply process simple forgings. Relatively lower cost.

QUALITY CONTROL CENTER

Our quality control center has magnetic particle flaw detector, tensile testers, electron microscopes, CMMs, hardness testers, and chemical property testing instruments such as salt spray laboratories.Whether it is the selection of materials, monitoring of the production process or testing of the final product, we strictly control it to ensure that every product meets customer requirements and expectations. Contact us for a quote or to learn more about our metal forging services.

-

Tensile Testing Machine

It is used to test mechanical properties such as static load, tension, compression, bending, shearing, and peeling of forgings.

-

CMM

It can accurately measure the size and shape of forgings.

-

Hardness Tester

Brinell and Rockwell hardness testers can quickly and accurately test the hardness of forgings.

-

Chemical composition detection machine

Detect the types and contents of elements in castings.

-

Salt Spray Test Machine

Place the casting in a simulated environment to test its oxidation resistance, corrosion resistance, etc.

-

Magnetic Particle Flaw Detector

It is divided into two types: fluorescent magnetic particle testing and non-fluorescent magnetic particle testing, which can detect surface and near-surface defects of forgings.

PROCESS OF HOT FORGING FACTORY COMPLETE YOUR ORDER

In the production process of forgings, the first thing HULK Metal has to do is to determine the forging process and know what process methods are available in order to forge the forgings for the next step, conduct technical and economic analysis and select the best process plan. Next, let us see how the forging procedure is determined.

-

PART 01Custom A Suitable Solution

PART 01Custom A Suitable SolutionAfter receiving your drawings, we will list multiple options based on the functional characteristics, material, shape, dimensional accuracy, quality requirements and production batch of the forgings, and select the best process option after conducting technical and economic analysis.

-

PART 02Purchase Raw Materials

PART 02Purchase Raw MaterialsWe calculate raw materials strictly in accordance with the drawing specifications and carry out accurate raw material procurement. We maintain close contact with our long-term raw material suppliers to ensure that each batch of raw materials meets standards and can provide complete test reports.

-

PART 03Model Making

PART 03Model MakingWe will manufacture appropriate molds based on the complexity, volume, and output of the forgings. Open die forging will use flat molds or special-shaped molds, while closed die forging will require more complex and custom-designed molds.

-

PART 04Order Scheduling

PART 04Order SchedulingAfter you confirm the order and receive the advance payment, we will start arranging production according to the order sequence to ensure on-time delivery.

-

PART 05Hot Foging

PART 05Hot FogingWe will choose between open die forging or closed die forging based on the unique needs of our customers. Open-die forging offers economy and flexibility, while closed-die forging stands out for its precision and productivity.

-

PART 06CNC Maching

PART 06CNC MachingPlace the special sandbox on a three-dimensional vibrating table, pour in the bottom sand, shake, and spread it evenly. Finally, put in the model coated with refractory material, continue filling with sand, and vibrate. Attach the membrane so that it is under negative pressure.

-

PART 07Heat Treament

PART 07Heat TreamentThe metal smelting process is very complicated and will not be described in detail here. If you have castings that need manufacturing, kindly contact our sales managers. They will give you a complete solution.

-

PART 08Surface Treatment

PART 08Surface TreatmentIn order to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of forgings, we will perform surface treatment on them.

-

PART 09Quality Inspection

PART 09Quality InspectionWe will test the material, size, weight, appearance, physical properties (hardness, yield strength, tensile strength, impact energy), non-destructive testing (magnetic particle testing, ultrasonic, penetrant testing, eddy current testing) of forgings.

-

PART 10Packaging & Warehousing

PART 10Packaging & WarehousingAfter passing the inspection, we enter the packaging stage, which includes coating with anti-rust oil, wrapping with stretch film, dust bags, pallets, cartons, etc. We can also package according to customer requirements.

-

PART 11Delivery

PART 11DeliveryWe are equipped with a freight consultation center to find the best transportation solution for customers through precise screening to ensure faster and more efficient delivery services.

-

PART 12After Service

PART 12After ServiceWe will provide customers with a full range of services and support. Whether it is product usage guidance, maintenance or troubleshooting, we can respond in a timely manner and provide help.

PARTS HULK METAL HOT FORGING FACTORY

The hot forgings we produce have been used in many fields. We continue to optimize production processes, strictly control quality, and are committed to providing customers with reliable, high-quality customized solutions, and have won widespread trust and praise. If you need metal hot forging services, please contact our online engineers for a quote.

-

Steel Cable Grips

Steel Cable GripsSteel Cable Grips are made of high-strength seamless steel pipes. They are formed by hot die forging and undergo strict quenching and tempering. They have many superior properties.

READ MORE

-

Trailer Spare Parts

Trailer Spare PartsHULK Metal is committed to providing you with a variety of trailer spare parts to meet your diverse needs and application scenarios. Our extensive product line includes but is not limited to, hitches, brackets, wheels, braking systems, and connectors.

READ MORE

-

Wire Cable Grips

Wire Cable GripsCrafted from premium-grade alloy steel, this wire cable grip offers exceptional robustness and durability, guaranteeing long-lasting performance even under the most demanding conditions.

READ MORE

-

Cable Grip Puller

Cable Grip PullerCable grip puller is manufactured from high-quality alloy steel/carbon alloy, ensuring strength, durability, and wear resistance. Its excellent grip performance prevents slipping, even under wet and muddy conditions.

READ MORE

-

Toggle Clamp

Toggle ClampDesigned specifically for safety needs during pickup bed closing, our toggle clamp uses flexible handle movement to easily clamp a U-bolt or hook, place it precisely around the corresponding latch, and pull it down with ease to the locked position.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesOur lifting devices are carefully designed to solve situations where the load is too heavy to be lifted manually, or where the load needs to be lifted regularly and manual lifting would cause unnecessary stress to the operator.

READ MORE

More Results

CHOOSING HULK METAL AS OEM FORGING FACTORY YOU WILL GET

HULK Metal focuses on customer needs and provides customized services to meet your special requirements. No matter what specifications and materials you need, we can provide you with the best metal forging solution.

-

Experienced Skills

HULK Metal has long experience in metal forging processing services and has established a skilled team to provide customers with services from design to product. Kindly contact us to get a quote.

-

Excellent Quality

The QC center will strictly control the quality of the products to ensure that each product is produced under quality requirements.

-

High Efficiency

Extensive facilities allow for a variety of processing techniques, and we can support customers to quickly obtain quotes, put them into production, and shorten delivery times.

-

Reasonable Price

HULK Metal has sufficient in-house facilities to select the best processing solution, reduce production costs, and provide customers with competitive prices.

ARTICLES OF HOT FORGING FACTORY

Here is more latest information about hot forging plants. We will update articles regularly. You can click on the link below to read. If you want to know more information, please contact us!

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

July 03, 2024

What are the processes of hot forging?

READ MORE