HULK Metal has more than 20 years of die forging production experience and focuses on providing comprehensive metal forging services, including open die forging and closed die forging processes. Our unwavering commitment to quality and precision solidifie

HULK Metal

Precision Die Forging Service Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Factory

-

Introduction

-

Articles

-

Review

-

Top

START DIE FORGING SERVICES AT HULK METAL

Our advanced forging facilities, skilled workforce, and strict quality inspection team ensure that every forged component we produce meets the highest standards of durability, reliability, and performance. Trust HULK Metal to provide forging solutions that exceed expectations and drive your projects to new heights of success.

-

Factory:

HULK Metal With extensive experience in precision machining, we ensure that your forged components are of the highest level of precision and quality. Whether you require custom design, superior strength or tight tolerances, our skilled team can meet your requirements and you can trust us with your order.

-

Experience:

In the Forging industry, experience counts. We provide hot forging production of carbon steel, alloy steel, stainless steel and other metal materials to global customers. The main types of forgings we have produced include construction hardware, trailer parts, automotive exterior decoration, powerline hardware accessories, fitness equipment, mining machinery parts, Agricultural machinery, forestry machinery, engineering machinery, etc., 0.1-500 kg, accuracy can reach international advanced hot precision forging standards. Contact us and we can give you an online quote.

-

Quality:

Our state-of-the-art quality control center is equipped with state-of-the-art testing equipment, capable of comprehensive evaluation including hardness, surface roughness, dimensions, geometry and other relevant parameters customized to your specifications. After testing is completed, we provide comprehensive materials and forging inspection reports. In addition, if you need a test report issued by a third-party testing agency, we can also assist. Trust us with your order.

-

Services:

In order to meet the different needs of customers around the world, we utilize our strong and comprehensive metal die forging capabilities to enrich our products. Our focus is on the manufacturing and supply of forgings, castings and precision machined parts. We can provide a series of customized designs such as sheet metal cutting, welding, surface treatment, heat treatment, assembly, etc., ultimately forming a comprehensive solution and one-stop service.

DIE FORGING SERVICES CAPACITIES

Here, when choosing HULK Metal as your metal forging supplier, you should know some basic information, including accuracy, standards, surface treatment, minimum order quantity, etc. Through the following form, you can learn more about our metal die forging service, if you have drawings or samples of forgings, you can send them to us online and we will provide you with a quotation as soon as possible.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS:

| Carbon Steel, Alloy Steel, Cold and Hot Moulded Shell Steel, Stainless Steel, Heat-resistant Steel and Other High Alloy Steel Parts |

Product Size | Available As Customer's Drawing Required |

Color | Customer's Requirements |

Mould | Design and produce by ourself |

Standard | ISO, DB34/T 1240-2010 etc. |

Weight Range | 0.01-500KG |

Machining Precision | ±0.01mm |

Surface Treatment | Trimming, Deburring, Polishing, Shot Blasting, Sand Blasting, Tumbling, Powder Coating, Anodizing, Passivation, Chemical Coating, Painting, Electroplating, Electrophoresis and so on. |

Production Diagram | Drawings or Samples > Mold Fabrication > Mold Test > Qualified Sample > Mass Production Die Casting > Deburring > Drilling&Tapping > Polishing > CNC Machining > Surface Treatment > Printing Logo > Quality Inspection > Packing > Shipping. |

MOQ | 500KG / A Standard Tray |

HOW YOUR DIE FORGINGS PRODUCED

Here, different forging methods have different processes. The general process of die forging process mainly includes blanking, heating, oxide scale removal, billet making, die forging, trimming, heat treatment, surface cleaning, correction, inspection and other processes. If you want to know more, please contact our online engineers.

-

01

Customize Solutions

Before starting production, we will design a comprehensive solution based on your specifications. We will then have an in-depth discussion with you to assess the feasibility of the proposed solution. After getting your approval, we will proceed with mold fabrication as per the agreed parameters and start sample trial production.

-

02

Mold Making

For open die forging, simple mold design can shorten the lead time of mold production. For closed die forging, the initial tool and die design is somewhat complex and will take longer in the initial stage. Once the die is in place, it is very suitable for mass production. We will conduct a comprehensive analysis of the specific requirements of the project and select the appropriate processing method.

-

03

Blanking

Blanking is an important preparation stage before the forging process. After calculating how much raw material is needed according to the drawing, the large continuous casting billet or steel ingot is divided into the required small pieces of raw material through cutting methods such as sawing machines.

-

04

Heating

In order to reduce the forging deformation force and improve the plasticity of the metal, make it easy to form, and obtain good post-forging structure and mechanical properties, we will conduct electromagnetic induction heating of the metal.

-

05

Die Forging

After the metal blank is heated to a temperature higher than the recrystallization temperature of the material, the metal blank is plastically formed into the shape and size of the forging using a mold. Hot forging has always played an important role in shaping metal parts with precision, strength and efficiency.

-

06

Trimming

According to the material and size of the forging, the residual heat of the forging is used to perform trimming immediately after die forging.

-

07

Finishing

Before heat treatment, we will first grind and polish the metal forgings to eliminate surface oxide scale and burrs and obtain a smooth surface.

-

08

Heat Treatment

Heat treatment is a special technique used to improve the properties of die forgings. It can change the crystal structure in the material, change the surface layer structure and improve the material's physical properties and its service life.

-

09

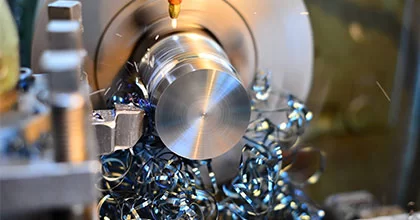

CNC Maching

Computer programming in CNC machines allows die forgings to be machined according to your needs. We have optimized every process parameter to make it easier to achieve high precision and good surface finish.

-

010

Surface Treatment

It is very necessary to perform surface treatment on hot die forgings. Common forging surface treatment processes include: spraying, electroplating, anodizing, impregnation, oil spraying, sandblasting and other processes.

-

011

Quality Control

In order to ensure that the quality of forgings meets the various indicators required for design and use, quality inspection of forgings (blanks, semi-finished products and finished products) is required. General forging quality inspection is divided into appearance quality inspection and internal quality inspection.

-

012

Warehousing

Our experienced warehousing team ensures your products are stored safely and managed efficiently. Whether you need short-term or long-term storage, we have flexible solutions for you.

-

013

Packaging & Delivery

Our experienced warehousing team ensures your products are stored safely and managed efficiently. Whether you need short-term or long-term storage, we have flexible solutions for you.

-

014

After Service

Whether it is technical support, parts replacement or problem solving, we will solve it for you in a professional and timely manner.

PARTS HULK METAL DIE FORGING PRODUCED

The following is the completed die forging, all pictures are from the Internet. We will sign a confidentiality agreement with our customers and promise never to disclose customer information without permission. Please contact us immediately, our engineers will provide professional solutions based on your drawings and provide highly competitive prices.

-

ACSR Cable Conductor Gripper

ACSR Cable Conductor GripperA Cable Conductor Gripper is an essential tool designed for use with steel wire, Aluminum Conductor Steel Reinforced (ACSR) wire, or insulated wire. This versatile product is engineered to meet a wide range of applications.

READ MORE

-

Cable Grip Puller

Cable Grip PullerCable grip puller is manufactured from high-quality alloy steel/carbon alloy, ensuring strength, durability, and wear resistance. Its excellent grip performance prevents slipping, even under wet and muddy conditions.

READ MORE

-

Toggle Clamp

Toggle ClampDesigned specifically for safety needs during pickup bed closing, our toggle clamp uses flexible handle movement to easily clamp a U-bolt or hook, place it precisely around the corresponding latch, and pull it down with ease to the locked position.

READ MORE

-

Ball Mount

Ball MountHULK Metal can provide you with many types of ball mounts to meet your different needs and application scenarios. ball mount can be used for a variety of purposes, such as mounting a bike rack, mounting a spare tire, or a cargo rack.

READ MORE

-

Shackle Hitch Receiver

Shackle Hitch ReceiverHULK Metal's shackles are made of high-quality carbon steel, alloy steel, and stainless steel, with a safety factor of 4 to 6 times. A variety of specifications are available for you to choose from, and non-standard customization is supported.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesOur lifting devices are carefully designed to solve situations where the load is too heavy to be lifted manually, or where the load needs to be lifted regularly and manual lifting would cause unnecessary stress to the operator.

READ MORE

More Results

DIE FORGING TYPES HULK METAL CAN SUPPLY

You can find the metal molding services you're more interested in based on material here. We can finish carbon steel, alloy steel, stainless steel materials. You can contact us for solutions and quotes.

Carbon Steel Die Forging

Alloy Steel Die Forging

Stainless Steel Die Forging

-

Carbon Steel Die Forging

Carbon steel is widely used in many industries and it has gained popularity due to its economical approach. High carbon steel is divided into low carbon steel, medium carbon steel, high carbon steel and very high carbon steel. We will process and produce according to the requirements of the drawings. If you need customization, please contact us!

-

Alloy Steel Die Forging

We can produce stainless steel die forgings of various materials, including various types of austenitic stainless steel, martensitic stainless steel, duplex stainless steel, super stainless steel, etc. For batch die forgings, stainless steel die forgings of non-standard materials can also be customized for customers.

-

Stainless Steel Die Forging

There are various types of alloy steel die forgings depending on their application fields.Alloy steel is divided into low alloy steel, medium alloy steel and high alloy steel,in order to facilitate the formulation of the process and the selection of the appropriate forging method, so as to have a standardized design procedure, our team of engineers will conduct a collective discussion and formulate several feasible solutions for you to choose from.

VISIT HULK METAL DIE FORGING FACTORY

Our die forging factory is one of your reliable partners, providing you with high-quality die forging services. Our die forging factory strictly follows the ISO 9001 international quality management system standard to ensure that the products meet the highest quality standards. We are equipped with advanced equipment, adopt rigorous processes and strict management to ensure the efficiency and stability of the production process. We invite you to contact our engineers to arrange an online or on-site tour of our factory. Looking forward to further cooperation with you.

-

Equipment

The factory has multiple forging equipments that can quickly process orders and put them into production. Whether it's a complex part or a standardized product, we ensure quality and delivery time.

-

Production Team

Our team of engineers and workers have at least ten years of operating experience and can handle every order skillfully.

-

QC Center

The quality inspection center can inspect everything from raw materials to finished products. We implement multi-level inspections to ensure that each product meets high standards. Advanced technology is used to conduct non-destructive and destructive testing to ensure product reliability and durability.

DIE FORGING SERVICES INTRODUCTION

Here we will briefly introduce the knowledge of die forging, such as what is die forging and the advantages and disadvantages of die forging. At that time, we also briefly explained the benefits you can get by choosing HULK Metal's die forging services.

-

Die Forging Means:

Die forging is a forging method that uses a die to shape a blank on a special die forging equipment to obtain a forging. The material's grain structure is optimized, improving the strength, toughness and wear resistance of the forging while reducing the need for subsequent machining. We can provide open die forging and closed die forging services to meet the specific requirements of various industries and provide high quality parts.

-

Advantages and Disadvantages of Die forging:

Advantages:

1. Precise shape and size, 2. High surface finish, 3. Improved mechanical properties and service life.

Disadvantages:

1. Compared with open die forging, closed die forging molds are more expensive,2. Process flexibility is lower, 3. Long production preparation period.

HULK Metal also manufactures standardized products such as handrails and guardrails systems, concrete precast accessories, glass clamps, and aluminum-plastic panels.

ARTICLE OF DIE FORGING

Here are the articles about metal die forging that we have collected and organized. They cover the knowledge of die forging, including raw materials, types, advantages and disadvantages, processes, etc. We also did some supplier comparisons. Hope you gain something.

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

July 03, 2024

What are the processes of hot forging?

READ MORE