HULK Metal focuses on providing excellent machining capabilities and collaborative services. We provide comprehensive CNC machining services, covering CNC turning, milling, turning and milling and other processes.

To Supply More Precision Forgings

HULK Metal Forging Machining Factory

-

Introduction

-

Equipment

-

Machining Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

We are a professional machining factory with five-axis linkage machining centers, 4-axis and 3-axis CNC machine tools, and equipped with lathes, grinders, spark machines, wire cutting machines and other processing equipment. With strong production capacity, we are able to flexibly arrange the production cycle to meet customers' various product production needs and provide you with professional, efficient and convenient machining services.

HULK METAL MACHINING FACTORY EQUIPMENT

Here we show you the equipment configuration of our machine shop. If you have machining needs, please contact our online engineers directly. He will tailor a solution based on your requirements and provide a competitive quote.

-

01Three-axis Machining Center

As the absolute main model of the machining shop, the 3-axis machining center can machine most precision parts and is suitable for processing discs, sleeves and plates.

-

02Four-Axis Machining Center

4-axis milling can work on up to 4 sides without the need for any fabricated jigs or cutting tools.

-

03Five-Axis Machining Center

Five-axis machining is the most accurate and advanced method for manufacturing complex precision metal parts on the shop floor and can machine parts with more complex shapes.

-

04CNC Machining Center

Used to simply process forging surfaces, holes, threads, etc. Relatively lower cost.

MACHINING FACTORY CENTER

Here is a display of forgings being processed in our processing factory. Kindly contact our engineers if you want to visit the factory. They will take you to visit on-site or online and provide detailed explanations.

-

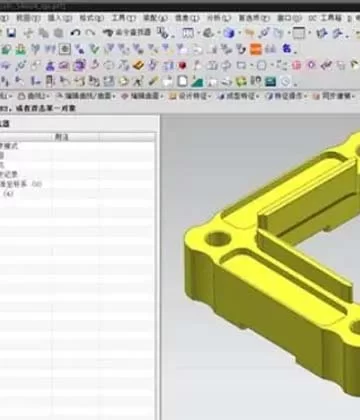

Programming

Carry out CNC programming according to drawings.

-

Program Adjusting

Adjust the forging and corresponding program according to the machining surface.

-

Adjust Flatness

Adjust the position and flatness of the forging fixation.

-

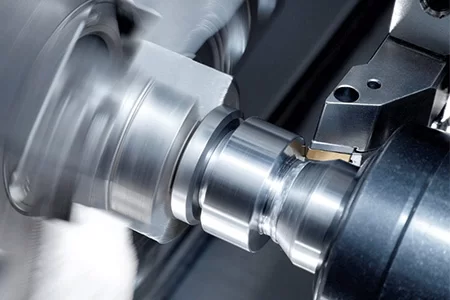

Turning

Cut off excess metal material to achieve the desired shape and size.

-

Milling

Use milling technology to effectively improve machining accuracy and tolerances.

HOW HULK METAL MACHINING FACTORY COMPLETE YOUR ORDERS

We are committed to providing complete processing solutions to help customers effectively control order costs. With our rich experience and advanced technology, we are able to customize precision parts that meet customer needs and achieve high efficiency and quality output during the production process. By choosing us, you will get a professional and reliable partner to jointly achieve the success and development of your project.

-

PART 01Custom Solution Based on Drawings

PART 01Custom Solution Based on DrawingsAccording to the drawings and specific requirements provided by customers, we will develop efficient solutions for you. We have a variety of processing equipment and an experienced technical team, which can complete various metal processing quickly and accurately.

-

PART 02Determine the Machine and Programming

PART 02Determine the Machine and ProgrammingSelect the appropriate CNC parts processing machine tool by comprehensively considering the material, shape, size, accuracy and other factors of the forging.

-

PART 03Forgings Fixing

PART 03Forgings FixingCommon fixing methods include clamp type, magnetic suction cup, vacuum adsorption, and tooling fixation. Determining the logical relationship between the fixed surface and the processing surface can improve the processing efficiency and qualification rate of forgings.

-

PART 04Machining

PART 04MachiningMechanical processing mainly includes two categories: manual processing and CNC processing. Manual processing refers to a method in which mechanical workers manually operate mechanical equipment such as milling machines, lathes, drilling machines, and sawing machines to process various materials. Manual machining is suitable for the production of small batches and simple parts.

-

PART 05Quantity Control

PART 05Quantity ControlThe surface accuracy, shape, and tolerance of processed castings are inspected.

-

PART 06Surface Treatment

PART 06Surface TreatmentDifferent forgings require different surface treatment methods, so the appropriate treatment method must be selected according to the specific situation.

FORGINGS HULK METAL HAVE MACHINED

Here, we have successfully processed thousands of forgings, ranging from 0.5kg to 50kg, covering a wide range of application fields. During the processing process, we strictly follow the confidentiality agreement to ensure that the customer's product design and technical data are fully protected to Meet customers' needs and protect their business interests.

-

ACSR Cable Conductor Gripper

ACSR Cable Conductor GripperA Cable Conductor Gripper is an essential tool designed for use with steel wire, Aluminum Conductor Steel Reinforced (ACSR) wire, or insulated wire. This versatile product is engineered to meet a wide range of applications.

READ MORE

-

Wire Grips For Wire Rope

Wire Grips For Wire RopeThe wire grips for wire rope we produce are carefully crafted from high-strength alloy steel. Each wire grip undergoes a rigorous process during the manufacturing process, including hot forging, heat treatment, and precision machining.

READ MORE

-

Wire Grips For Guy Wire

Wire Grips For Guy WireWell-designed and durable, our wire grip for guy wire embodies the highest standards of quality and reliability. It uses advanced materials and cutting-edge manufacturing techniques to ensure excellent durability and wear resistance.

READ MORE

-

Toggle Clamp

Toggle ClampDesigned specifically for safety needs during pickup bed closing, our toggle clamp uses flexible handle movement to easily clamp a U-bolt or hook, place it precisely around the corresponding latch, and pull it down with ease to the locked position.

READ MORE

-

Ball Mount

Ball MountHULK Metal can provide you with many types of ball mounts to meet your different needs and application scenarios. ball mount can be used for a variety of purposes, such as mounting a bike rack, mounting a spare tire, or a cargo rack.

READ MORE

-

Shackle Hitch Receiver

Shackle Hitch ReceiverHULK Metal's shackles are made of high-quality carbon steel, alloy steel, and stainless steel, with a safety factor of 4 to 6 times. A variety of specifications are available for you to choose from, and non-standard customization is supported.

READ MORE

More Results

CHOOSE HULK METAL MACHINING YOU WILL GET

HULK Metal is committed to providing you with excellent machining services. Choose us, you will get lower order costs, save more time and energy, and faster delivery. We provide one-stop system solutions to ensure your satisfaction.

-

Get Higher Quality Forgings

Our forgings undergo precision craftsmanship to ensure each product meets the highest standards. We use advanced materials and processes to ensure that forgings can exhibit excellent strength and toughness under various application conditions. Whether under high temperatures, high pressures or extreme loads, our products operate robustly and reliably, providing customers with long-lasting and reliable solutions.

-

Get Goods Faster

We provide efficient machining services and are committed to faster delivery. With advanced equipment and technical team, we ensure high quality and on-time delivery. By optimizing production processes and strict quality control, we are able to respond quickly to customer needs and ensure the shortest delivery cycle. Welcome to consult online, we will wholeheartedly provide you with professional services.

-

Spend Less Money

We focus on providing solutions that maximize cost-effectiveness. Through precise production planning and optimized processing processes, we are able to save material and energy costs to the greatest extent, improve production efficiency, and ensure product quality.

-

Spend Less Time & Energy

We have an efficient and collaborative team, covering professionals in various fields such as technology, procurement, production, quality inspection, freight consulting and after-sales. Through the close cooperation and unremitting efforts of the team, we have always maintained a high level of production standards and customer satisfaction, providing customers with the most reliable and precise processing solutions.

ARTICLES OF METAL FORGING & MACHINING

Here are the articles we have compiled about forging machining. You can find what you want to know here. Kindly contact us if you have a forging order and need OEM.

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

March 28, 2025

Hot Forging and CNC Machining: An Inseparable Combination in Modern Manufacturing

READ MORE

-

March 24, 2025

Choosing the Right CNC Machine Company

READ MORE

-

March 07, 2025

What to look for when looking for a Forging Manufacturer?

READ MORE

-

December 13, 2024

HULK Metal CNC Machining:Make your life easier

READ MORE