Mold is the cornerstone of precision and durability, critical to manufacturing quality forged products. HULK Metal customizes each mold according to the specific requirements of the forging process, optimizing efficiency and product quality.

HULK Metal

Precision Making Mold For Metal Forging

-

Home>

-

Mold Making>

-

Capacities

-

Processes

-

Industries

-

Factory

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

MOLD MAKING SERVICE CAPACITIES

Here, our comprehensive mold making services cover every stage of the production process, from initial design and prototyping to final inspection and delivery. Mold Fabrication As part of our metal forging services, we are equipped with an excellent team and advanced technology to ensure that your unique preferences and requirements are seamlessly integrated into the mold design.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS:

| Cold Work Die Steel, Hot Work Die Steel, Customizable |

Molds for Casting:

| Hot Forging,Die Forging |

Process: | CNC Machining, Heat Treatment |

PROCESSES OF YOUR METAL FORGING MOLD PRODUCED

The following is the process flow of forging mold making. Mold making plays a vital role in industrial production, which determines the quality, cost, and production efficiency of forgings. You can contact our online engineers for more forging mold making details.

-

01Analyze Drawings & Customize Solutions

01Analyze Drawings & Customize SolutionsUnderstand the customer's needs and requirements for forgings according to the drawings, including materials, dimensions, quality, etc., and develop a feasible solution.

-

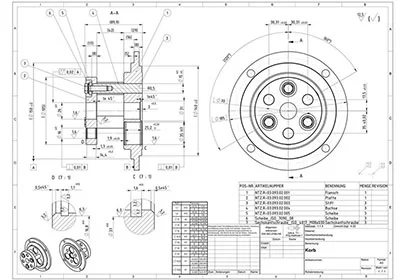

02Draw Mold Drawings

02Draw Mold DrawingsBased on the mold structure and part arrangement in the solution, designers use computer simulation technology to develop forging product molds.

-

03Raw Material Purchasing

03Raw Material PurchasingUsing new hot forging die steel materials, H13, 3Cr2W8V, LG, 8566. 8566 has good high temperature resistance, using hardness HRC58-60, high hardness and good wear resistance. LG mold steel has very good toughness, with a hardness of HRC54-56. H13 is the medium-grade hot work die steel we commonly use at present.

-

04Mold Processing

04Mold ProcessingThe formation of a set of molds requires a variety of processes. Mold materials must be carefully selected and properly heat treated. Advanced processing technology must be used to ensure the accuracy and surface quality of the mold cavity.

-

05Assembly & Commissioning

05Assembly & CommissioningAfter the forging mold is assembled, it must undergo strict debugging and testing procedures. This includes inspection of the geometry of the forging die module, inspection of the forging die cavity size, die cavity surface roughness inspection, mold heat treatment inspection, etc.

-

06Trial Production

06Trial ProductionTrial production is the main part of mold acceptance. The purpose is to optimize the mold and facilitate subsequent mass production.

-

07Deliver or Start Orders

07Deliver or Start OrdersAfter the mold is made, we will deliver it. If you give us your forging order, we will start mass production.

-

08After Service

08After ServiceDuring the use of the mold, we will provide you with lifetime free technical consultation at any time, and provide satisfactory and convenient after-sales service to all users in all regions around the world.

START MAKING MOLD FOR METAL FORGING AT HULK METAL.

HULK Metal's mission is to provide our customers with quality metal forging mold services. Our long-term focus on mold manufacturing ensures that forging technology is pushed to its limits.You can send questions or concerns online or by email and we'll get the help you need.

-

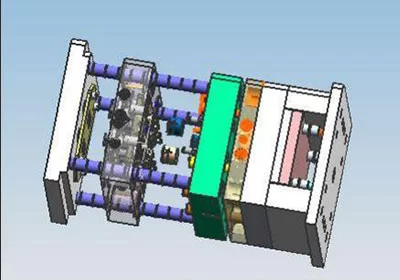

Factory

HULK Metal has advanced mold making equipment, including milling machines, heat treatment equipment, grinders, CNC machining centers, EDM, WEDM, JIG GRINGING, laser engraving machines, polishing machines, etc. We have produced thousands of sets of molds, whether complex patterns, specific sizes or unique features, our skilled craftsmen will ensure that each mold is crafted to your precise requirements.

-

Experience

Our expertise in mold making for over two decades is a hallmark of quality and precision. We specialize in making forging molds that meet different needs, ensuring optimal functionality and durability. Our experienced team of engineers and technicians employ state-of-the-art technology and strict quality control measures to deliver superior products. Trust our innovative solutions and exquisite craftsmanship in mold production.

-

Quality

We have professional mold testing equipment, such as three-dimensional coordinate measuring machines, optical trackers, hardness testers, etc., to ensure that each mold meets the highest quality standards. With meticulous attention to detail and a commitment to continuous improvement, we guarantee product reliability and durability. You can contact us online or visit the factory on site.

-

Service

As a leading supplier of metal forging solutions, we excel in tool making, a key aspect of our service portfolio. One-stop service from initial design to precision machining, guaranteeing top-quality molds tailored to your specifications. Trust us to meet your mold manufacturing needs.

METAL FORGING TYPES HULK METAL CAN SUPPLY

Here, let us shed light on the range of metal forging services we offer, specializing in providing hot die forging of carbon steel, alloy steel, stainless steel, For more details please refer to the link provided.

-

Hot Forging Service

-

Die Forging Service

-

Hot Forging Service

Hot forging is a manufacturing process in which metal is shaped and formed into the desired structure at high temperatures, usually above the material's recrystallization temperature. The method involves heating a metal blank or workpiece to a ductile state so that it can be more easily deformed and manipulated into the desired shape by applying compressive force. Hot forging is widely used in industrial settings because it produces components with superior strength, durability and structural integrity compared to components manufactured by cold forging or other processes.

-

Die Forging Service

The process of die forging is blank manufacturing, pre-forging and final forging. The cavity of the final forging die depends on the required forging size and shape, as well as allowances and deviations. Die forging is generally divided into two types: open die forging and closed die forging. Choosing between open die forging and closed die forging depends on the unique needs of your manufacturing project. Open die forging is known for its flexibility and economy, while closed die forging stands out for its precision and productivity. When making your decision, it is important to weigh aspects such as budget, production volume, and the complexity of the parts required. For all your forging requirements, HULK METAL can help you get it done.

MOLD MAKING OF METAL FORGING INTRODUCTION

Below we will introduce to you some content of mold manufacturing used in metal forging, what is a forging mold, and materials of forging molds, etc. We will also introduce the benefits of choosing us as your mold manufacturing service provider. If you want to know more, you can contact our engineers or browse the Blog.

-

Mold Making of Metal Forging Means

Mold Making of Metal Forging is the process of analyzing the product of forged parts, determining the die forging forming method, proposing a process plan, designing the forming process drawing, and finally processing the finished product. Forging molds are the main process equipment for producing forgings. Forging mold processing has gone through development stages such as profiling processing, electrolysis and EDM, CNC machining, and high-speed machining technology. If you want to know more about forging molds making, please contact us.

-

Materials of Molds of Metal Forging:

H13:

This steel has high hardenability and resistance to hot cracking, good heat resistance, and good wear resistance. It is currently a commonly used medium-level hot work die steel.

8433:

The high temperature softening resistance of 8433 mold steel is 2 to 3 times that of H13. The mold is not easy to soften, the hardness can reach HRC50-54, and the toughness is good.

8566:

8566 mold steel is a multi-purpose comprehensive cold work tool steel, which is higher than LG mold steel in terms of heat resistance and wear resistance.

LG:

The hardness and strength of LG mold steel is higher than that of 8566 mold steel. LG mold steel has better performance under larger loads and high temperature environments.

What You will Get When Choose Our Mold Making of Metal Forging Service.

As a professional metal forging service supplier, HULK Metal not only has large-scale forging equipment to meet various needs for forgings but also has its own mold workshop. You no longer need to look around for products, we can provide you with a full range of services, from concept to to product design, engineering, manufacturing, testing, and verification, committed to becoming your trusted supplier. Contact us now.

Hulk Metal is committed to providing higher standards of products and services for hardware customers. You will get our best products and metalworking services in Hulk Metal.