HULK Metal is meticulous in every aspect of the forging process, including design, mold making, blank forging, surface treatment, forging process and quality assessment. Our strict quality control reflects a commitment to excellence, ensuring flawless res

HULK Metal

Precision Metal Forging Service

-

Home>

-

Metal Forging>

-

Advantages

-

Capacities

-

Processes

-

Industries

-

Types

-

Introduction

-

Articles

-

Review

-

Top

Custom Metal Forging Services

We are committed to providing exceptional metal forging services, continually improving our capabilities in four key areas. We are steadfast in supporting you on your journey to industry excellence, ensuring every forged component is of unparalleled quality and reliability.

-

Factory:

We have focused on the forging industry for more than 20 years, with an annual production capacity of 150,000 tons. Our forging production technology is strong, relying on scientific management, exquisite craftsmanship, excellent quality, and perfect service to win the recognition of our customers.

-

Experience:

The metal forging services we provide cover multiple industries, including construction hardware, trailer manufacturing, automotive exterior decoration, powerline hardware, fitness equipment and other industries. Our customers come from all over the world and we provide valuable solutions according to their individual needs.

-

Quality:

Throughout the entire order process, we strictly control the quality of our products. From the beginning of trial production, we will test the size, appearance, weight, physical properties, non-destructive testing, etc. of the product at every step. Only after passing the test will it be put into mass production, and finally we will conduct warehousing inspection and shipping inspection. Ensure products are delivered that meet customer expectations.

-

Service:

In order to meet the diversified requirements of global customers, relying on strong and complete metal forging capabilities, we have expanded our product lines and are committed to the production and supply of forged parts, castings, and profile machined parts, including cutting sheet metal, welding, surface treatment, and heat treatment , assembly and other overall solutions and one-stop services, thereby providing high value-added finished parts.

METAL FORGING SERVICE CAPACITIES

Here we offer a comprehensive range of forging services to meet your specific requirements. Our products cover a variety of metals, processes, piece weight specifications, production capabilities, certifications and finishing capabilities. For more information and detailed insights, feel free to contact us!

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS:

| Carbon Steel, Alloy Steel, Cold and Hot Moulded Shell Steel, Stainless Steel, Heat-resistant Steel and Other High Alloy Steel Parts |

Product Size | Available As Customer's Drawing Required |

Color | Customer's Requirements |

Mould | Design and produce by ourself |

Standard | ISO, DB34/T 1240-2010 etc. |

Weight Range | 0.01-50KG |

Machining Precision | ±0.01mm |

Surface Treatment | Trimming, Deburring, Polishing, Shot Blasting, Sand Blasting, Tumbling, Powder Coating, Anodizing, Passivation, Chemical Coating, Painting, Electroplating, Electrophoresis and so on. |

Production Diagram | Drawings or Samples > Mold Fabrication > Mold Test > Qualified Sample > Mass Production Die Casting > Deburring > Drilling&Tapping > Polishing > CNC Machining > Surface Treatment > Printing Logo > Quality Inspection > Packing > Shipping. |

MOQ | 500KG / A Standard Tray |

HOW YOUR METAL FORGING PARTS PRODUCED

Should you seek a deeper understanding of our metal forging service process, our dedicated team of online engineers stands ready to provide comprehensive explanations at your convenience. Simply reach out to us, and we will be delighted to assist you with any inquiries you may have.

-

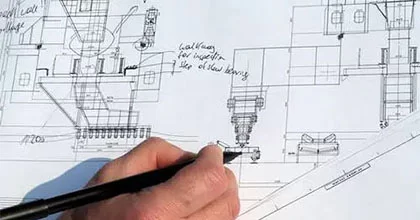

01

Customize Solutions

We provide tailor-made solutions based on drawings and provide you with detailed pricing calculations. After the order is confirmed, our professional team will start the mold manufacturing process and conduct sample production.

-

02

Mold Making

We provide customers with different types of molds based on the batch size, material, and shape of the forgings. For small batch production of forgings, try to choose a mold with a simple structure, and the life of the mold can also be lower. For mass-produced forgings, the mold structure will use multi-step molds such as billet making, pre-forging and final forging to ensure that the entire set of molds has a long life.

-

03

Forging Billet Blanking

Forging billet blanking is the preparation process before forging. After we calculate how much raw material is needed according to the drawing, we cut the large continuous casting billet or steel ingot into small pieces of raw material. Our most commonly used blanking method is the billet shearing machine.

-

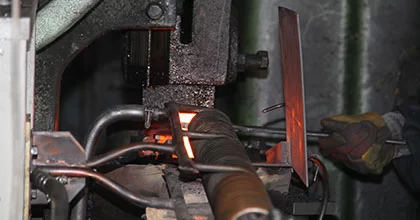

04

Heating

In order to improve the plasticity of metal, we usually use an electric furnace to heat the material. Forging heating is an indispensable and important process in hot forging production, which directly affects the quality and performance of forgings.

-

05

Forging

Die forging can forge many products with complex structures with high precision. The dimensional tolerance of the product can be controlled and the amount of machining can be reduced. For customers with high quality requirements, die forging is the best choice.

-

06

Trimming

We usually complete the trimming immediately after forging without reheating.Trimming while hot can avoid burr cracks.

-

07

Finishing

To remove surface oxide scale and burrs to make the workpiece beautiful, we will grind, sandblast, shot blast, pickle, etc. the forgings, and flexibly choose the processing method according to the material and shape of the forgings.

-

08

Heat Treatment

To remove surface oxide scale and burrs to make the workpiece beautiful, we will grind, sandblast, shot blast, pickle, etc. the forgings, and flexibly choose the processing method according to the material and shape of the forgings.

-

09

CNC Maching

With state-of-the-art CNC machining centers and a team of skilled engineers, we offer a comprehensive range of capabilities including milling, turning, grinding, and EDM. From prototyping to large-scale production, we deliver precision parts with tight tolerances, superior surface finishes to meet our clients' exact specifications and requirements.

-

010

Surface Treatment

We carry out surface treatment processes such as coating, electroplating and passivation on forgings as required to form a protective layer. In addition, surface treatments can enhance functionality by reducing friction, increasing conductivity or providing better adhesion for subsequent processes, ensuring optimal performance and longevity.

-

011

Quality Control

We have a professional quality inspection team and a complete quality inspection process. We are able to conduct a comprehensive evaluation and provide detailed reports on forging materials, size, shape, performance and other related parameters according to customers.

-

012

Warehousing

For raw materials, semi-finished products, finished product processing, finished product storage, combined packaging, delivery, etc., we have carried out a reasonable layout design of the warehouse to provide customers with additional value-added services and improve customer satisfaction.

-

013

Packaging & Delivery

We offer a range of packaging solutions, including wooden and cardboard boxes,Utilizing items like Styrofoam and bubble paper ensures secure product placement within packages. Moreover, we accommodate customization requests to meet specific client preferences. Benefit from expedited delivery options through our freight consulting services, enhancing overall efficiency.

-

014

After Service

We treat after-sales service as an important task and continue to improve and innovate to adapt to changes in market and customer needs and achieve the company's long-term development goals.

INDUSTRIES HULK METAL FORGING FACTORY SERVED

Here we will introduce to you the industries involved in metal forging services, such as construction hardware, trailer manufacturing, automotive exterior decoration, power hardware, fitness equipment and other industries. If you want to know more, you can click on the text below to read.

-

Cable & Wire Grips

Cable & Wire GripsAs a professional cable & wire grips manufacturer, HULK Metal has carried out in-depth cooperation with world-renowned lifting machinery companies, and are committed to providing high-quality, reliable cable & wire grips. Based on advanced technology and strict quality control, we continue to innovate in research and development to ensure that our products meet industry standards and customer needs. In the process of cooperation, we are not only suppliers, but also partners, fully understanding customer needs and providing professional solutions. Our cable & wire grips are widely used in construction, highways, bridges, metallurgy, mining, slope tunnels, shaft management and protection and other industries to provide customers with stable and efficient working performance. We will continue to cooperate with world-renowned lifting machinery companies to jointly promote the development of the industry and create greater value for customers.

READ MORE

-

Trailer Accessories

Trailer AccessoriesOur hot forging facility specializes in manufacturing high quality trailer accessory forgings, providing our customers with a range of precision engineered and manufactured components. Our product line covers a variety of key components, including but not limited to shackles, tow balls, tow hooks, etc.

READ MORE

-

Construction Hardware

Construction HardwareWe provide professional construction hardware forging processing services, and are proficient in the processing technology of carbon steel, alloy steel, and stainless steel. Our forging process uses advanced technology and equipment to ensure product precision and durability. We have professional machining equipment that can meet the processing needs of various complex parts and ensure perfect fit and accuracy of products. In addition, we offer a variety of surface treatment options, including galvanizing, spray painting, and anti-corrosion treatments, to enhance product durability and aesthetics. Our heat treatment services ensure products achieve the required hardness and strength to suit the needs of various construction environments. Our team has extensive experience and expertise and is committed to providing the best solutions to our clients and ensuring projects are delivered on time and to the highest standards of quality.

READ MORE

-

Mining Equipment Spare Parts

Mining Equipment Spare PartsHULK Metal is a professional manufacturer focusing on the production of mining equipment spare parts, committed to providing customers with efficient and reliable solutions. We have established long-term and solid cooperative relationships with many mining equipment manufacturers and spare parts dealers, and can fully grasp the latest industry technologies and market demands. Our spare parts are strictly produced in accordance with international standards, covering multiple application areas such as mining, construction, oil fields, ships and ports, forestry, agriculture, etc., providing high-quality parts for any heavy machinery. Our rich experience means that we can provide the highest quality mining equipment and spare parts at the lowest price in the shortest time. By choosing HULK Metal, you will get a comprehensive guarantee of fast delivery, high-cost performance, and perfect after-sales support.

READ MORE

-

Forging Parts

Forging PartsAs a professional hot forging factory, HULK Metal has accumulated rich experience in many industries. We are committed to providing customers with high-quality forging solutions.

READ MORE

-

Metal Exterior Accessories For Car, SUV, Truck

Metal Exterior Accessories For Car, SUV, TruckHULK Metal can provide a series of metal exterior accessories, covering various precision components, including toggle clamps, bolts, etc., suitable for various types of cars, SUVs, and trucks. Each of our products is produced using advanced forging technology to ensure high strength, excellent elasticity, and long-term durability. These characteristics are critical for car, SUV, and truck applications. Please provide product drawings and samples, and our engineering team will provide a professional quotation based on your needs.

READ MORE

More Results

METAL FORGING TYPES HULK METAL CAN SUPPLY

Here we will introduce to you the types of metal forging services, mainly providing hot die forging, which is divided into open die forging and closed die forging. If you want to know more, you can click on the text below to read.

Hot Forging

Die Forging

-

Hot Forging

Hot forging service is forging under high temperature. In hot forging processing, the heated blank is extruded in a fixed mold into a process close to the finished product. This process can produce a large number of solid metal parts of aluminum alloys, copper alloys, steel or superalloys with irregular shapes and good mechanical properties. As a leading forging manufacturer, we can tailor best-in-class forging services to your specific needs. Whether you require a custom design, superior strength or tight tolerances, our highly skilled technical team can meet your requirements.

-

Die Forging

Die forging service is a process in which the heated blank is placed in a mold fixed on the die forging equipment for forging to obtain forgings of the required shape and size. Die forging is divided into open die forging and closed die forging. Open die forging is a forging method in which the flow of deformed metal is not completely restricted by the die cavity. During open die forging, the excess metal is along the direction perpendicular to the force. Directional flow forms burrs. In closed die forging, the blank is formed in a die cavity that is closed on all sides. No transverse flash will be produced, and a small amount of excess material will form longitudinal flash. Compared with open die forging. Closed die forging can greatly improve metal utilization. On the basis of understanding the needs of our customers, we will quickly respond to their needs and adjust our forging process within the fastest turnaround time to improve customer satisfaction with us.

METAL FORGING SERVICE INTRODUCTION

Below, we provide relevant information about metal forging, including its definition, advantages, disadvantages, and the benefits of forming a partnership with us. We invite you to interact with us and adopt our expertise. Please contact us today and let our engineers provide you with the best pricing based on your specific requirements.

-

Metal Forging Introcuction

Forging is a processing method that uses forging machinery to apply pressure to a metal blank to cause it to plastically deform to obtain forgings with certain mechanical properties, shapes and sizes. Forging can eliminate defects such as loose as-cast metal produced during the smelting process and optimize the microstructure. At the same time, due to the preservation of complete metal streamlines, the mechanical properties of forgings are generally better than castings of the same material.

-

Advantages and Disadvantages of Metal Forging:

Advantages:

1.High material utilization. 2. High forging precision. 3. High productivity. 4. Has good mechanical properties

Disadvantages:

1. The complexity of the parts is limited. 2. Mold is easy to wear and needs to be repaired later.

Why choose us for your metal forging services.

Every customer is unique, and we provide one-stop solutions based on each customer's specific needs. With our extensive experience in mold manufacturing and forging production, we can ensure that your forged parts have the highest level of precision and quality.You can send us drawings and we will provide you with an advantageous quotation as soon as possible!

HULK Metal also manufactures standardized products such as handrails and guardrails systems, concrete precast accessories, glass clamps, and aluminum-plastic panels.

ARTICLE OF METAL FORGING SERVICE

Here, we've compiled informational articles on the practice of metal forging. These resources include discussions of raw materials, various forging methods, process flows, and a comprehensive analysis of their respective advantages and limitations. In your quest to deepen your understanding of metal forging technology and further explore our professional services, we encourage you to review our articles.

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

July 03, 2024

What are the processes of hot forging?

READ MORE