We will record every bit of HULK Metal, our activities, order production, quality inspection, shipping, etc. We are always here.

HULK Metal Forging News

Record HULK Metal’s Dynamics

News

The latest developments of HULK Metal, factory live broadcasts, etc. can be seen here.

-

242025.01HULK Metal 2025 Spring Festival Holiday Notice

242025.01HULK Metal 2025 Spring Festival Holiday NoticeIn celebration of the Spring Festival, we will be closed from January 25 to February 4, 2025. During this period, we will reunite with our families and spend a happy and peaceful holiday together.

-

112024.12Analysis of the characteristics and main uses of wire grip for conductor

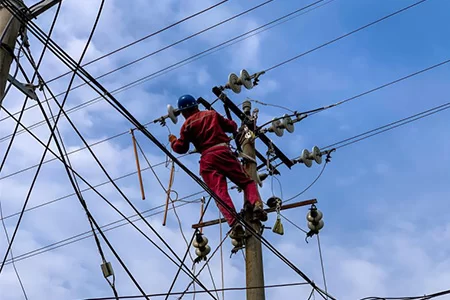

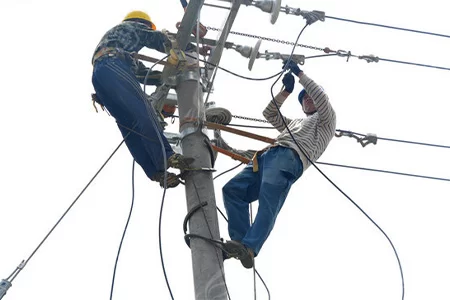

112024.12Analysis of the characteristics and main uses of wire grip for conductorWire grip for conductor is a well-designed and widely used power construction tool, especially playing a vital role in the construction process of overhead transmission lines.

-

142024.09Types of Jaw Wire Grip and Suitable Use Scenarios

142024.09Types of Jaw Wire Grip and Suitable Use ScenariosJaw Wire Grip is an important tool widely used in power engineering. It is mainly used to clamp, fix, or adjust transmission lines to ensure the smooth installation, maintenance, and overhaul of power lines.

-

132024.09Cable grip VS Wire Grip Comprehensive Detailed Analysis

132024.09Cable grip VS Wire Grip Comprehensive Detailed AnalysisCable grip and wire grip are two important tools widely used in the optical communication and power industry. Although they differ in function and structure, they both play a key role in their respective application fields.

-

122024.09Do you know the comprehensive analysis of wire grip puller?

122024.09Do you know the comprehensive analysis of wire grip puller?A wire grip puller is a tensioning tool designed to construct various overhead transmission lines (such as power cables and communication cables). It is mainly used to keep the wire in the correct position during line construction and maintenance and ensure that its tension meets the construction and safety standards.

-

062024.09Why can wire rope grip clamp cables?

062024.09Why can wire rope grip clamp cables?As an important wire gripping tool, Wire cable grip is widely used in the construction and maintenance of power, telecommunications, railways, and electrical overhead lines. This tool plays an indispensable role in improving construction efficiency and ensuring operation safety.

-

022024.09Things to note when purchasing a jaw wire grip

022024.09Things to note when purchasing a jaw wire gripA jaw wire grip is a wire gripping tool widely used in the construction and maintenance of overhead lines in power, telecommunications, and railway electrification. Its main function is to tension, fix, and pull conductors, stranded wires, or optical cables during the installation and maintenance of overhead lines.

-

272024.08Does the operation of wire grips conflict with oil lubrication?

272024.08Does the operation of wire grips conflict with oil lubrication?In the process of power construction, there are many kinds of tools involved, among which the wire grip is one of the indispensable and important tools. The wire gripper not only plays a key role in the construction and maintenance of overhead power lines but also in the operation of the entire power system.

-

262024.08How to use Jaw Wire Grips?

262024.08How to use Jaw Wire Grips?Jaw wire grip is a common and important tool for fixing wires and cables, and it is widely used in various industrial fields. In actual operation, the correct use method can not only improve work efficiency but also effectively extend the service life of wires and cables.

-

262024.07What kind of inspections should be done before choosing a wire gripper?

262024.07What kind of inspections should be done before choosing a wire gripper?A wire gripper is a key tool in wire stringing operations. It is usually used in conjunction with a wire tensioner. Its main function is to clamp the sagging line and then tighten it with the wire tensioner.

-

152024.07Wire Cable Grips: Types, Mechanisms, and Applications

152024.07Wire Cable Grips: Types, Mechanisms, and ApplicationsCable grips, also known as wire grips or come-along, are essential tools in the construction, maintenance, and inspection of various cable and wire systems. These devices are designed to meet the specific demands of different industries and wire specifications, providing standardized and efficient operational solutions.

-

012024.07Difference between hot forging and cold forging

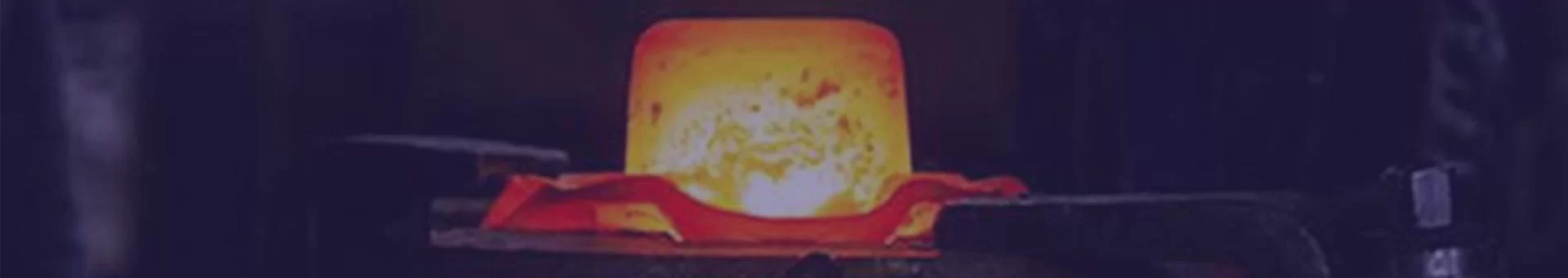

012024.07Difference between hot forging and cold forgingIn the field of metal processing, forging is an important manufacturing process that plastically deforms metal billets by applying pressure to ultimately obtain products of the desired shape and performance. Forging processes are mainly divided into two categories: hot forging and cold forging.

-

272024.06What are the advantages and disadvantages of the hot forging process?

272024.06What are the advantages and disadvantages of the hot forging process?Hot forging is a common metal-forming process that heats metal materials to deform them in a plastic state to obtain parts with the desired shape and performance. It is widely used in various industrial fields.

-

182024.01Forging: What Is It? What Are The Different Types of Hot Forging?

182024.01Forging: What Is It? What Are The Different Types of Hot Forging?Hot forging is a manufacturing process that changes the shape and properties of metal by heating it and applying pressure in a forging device. It is widely used in various industrial fields, such as Cable & Wire Grips, Trailer Accessories, Building Hardware, and Metal Exterior Accessories For Car, SUV, Truck, etc.

More Results