HULK Metal will continuously update the dynamics of the metal products industry, to support your decision-making.

Hulk Metal News

Share what's new

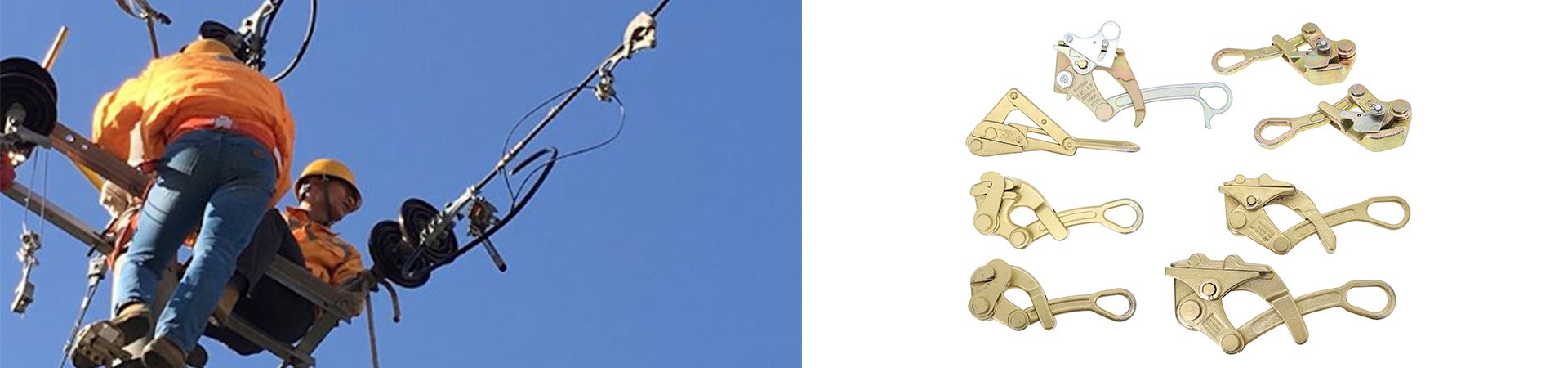

Do you know the comprehensive analysis of wire grip puller?

A wire grip puller is a tensioning tool designed to construct various overhead transmission lines (such as power cables and communication cables). It is mainly used to keep the wire in the correct position during line construction and maintenance and ensure that its tension meets the construction and safety standards. According to the different specifications of the cables used, users can choose a wire grip puller of corresponding specifications to ensure the effectiveness and safety of the operation.

Main uses of wire grip puller:

Power transmission:

In the power industry, wire grip pullers are widely used in the erection and maintenance of transmission lines. By applying appropriate tension, the wires are kept stably suspended in the air to avoid swaying and deviation of the wires caused by wind or other external factors.

Construction of communication lines:

In the communication industry, wire grip pullers are used for the erection of optical fiber cables or other communication lines to ensure that the lines are always kept in the designated position without external interference.

Aerial work:

In aerial work, wire rope grippers can be used as safety protection tools to ensure that construction personnel can firmly fix and maintain their working positions during operation.

Lifting application:

Wire grip pullers are also used in lifting operations in construction and other industries as tensioning and fixing tools to ensure the safety and stability of heavy lifting processes.

Other applications:

Wire grip pullers are also widely used on various occasions where cables and wire grip pullers need to be tensioned or fixed, such as on ships, bridges, trusses, and other engineering structures.

Wire Grip Pullers Process

The design and manufacture of wire clamps require a high degree of professionalism and fine craftsmanship to ensure their performance and safety in various applications. The process of wire rope grippers mainly includes the following aspects:

Material selection:

The material of the Wire grip puller is usually high-strength alloy steel, which has excellent mechanical properties and tensile strength and can withstand heavy loads and high-pressure tensioning operations. At the same time, the wear resistance and corrosion resistance of high-strength alloy steel also enable it to maintain good performance in harsh environments and extend its service life.

Heat treatment process:

In order to enhance the strength and toughness of the wire grip pullers, the material usually needs to undergo a sophisticated heat treatment process. This heat treatment process can effectively prevent the wire grip pullers from deforming or breaking under high load conditions, thereby ensuring its reliability under various working conditions.

Design details:

The design of the wire grip puller involves different clamping technology specifications to meet the requirements of cables of different diameters and sizes. For example, the small-sized wire grip pullers adopt a fine clamping structure to meet the tightening requirements of small-diameter cables, while the large-sized wire grip pullers adopt a stronger clamping method to ensure that thicker cables can be firmly clamped. The multi-sawtooth design increases the friction between the wire grip pullers and the cable, thereby improving the firmness of the clamping. In addition, the one-piece high-quality carbon steel structure and high-density gears further enhance the clamping ability and durability of the product.

Clamping technology:

The clamping part of the wire grip puller adopts a multi-sawtooth design, which can significantly increase the friction between the wire grip puller and the cable, making the clamping more tight and reliable. Combined with the one-piece structure of high-quality carbon steel and high-density gears, the wire grip puller can ensure the stability and safety of the clamping process while maintaining high strength, avoiding the risk of sliding or falling off.

Characteristics of the Wire Grip Pullers

The wire grip puller has many characteristics that make it perform well in actual operation, as follows:

Strong operability:

The design of the wire grip puller focuses on ease of use and operability, and both professional technicians and ordinary workers can easily master its use. During the cable installation and maintenance process, the wire grip puller can be quickly installed and adjusted to adjust the tension, effectively improving work efficiency.

Easy to maintain:

The wire grip puller adopts a modular design, the parts structure is simple, easy to disassemble and clean, and the daily maintenance workload is small. Its high-strength alloy steel material and surface anti-corrosion treatment process enable it to maintain excellent performance in various harsh environments, reducing the frequency of replacement and maintenance.

Easy to carry:

The wire grip puller is usually designed as a lightweight portable tool with moderate weight, easy to carry and operate, and is especially suitable for on-site construction and maintenance work that requires frequent movement. Its compact appearance and design make it easy to store and transport, reducing the burden on users.

How to choose a suitable Wire Grip Puller

Choosing a suitable wire grip puller is crucial to ensuring the safety and effectiveness of cable construction and maintenance. The following are the main factors to consider when choosing a wire grip puller:

Type of cable:

Different types of cables, such as fiber optic cables, copper core cables, or steel core aluminum stranded wires, have different requirements for the clamping force and adaptability of the wire grip pullers. When choosing a wire grip puller, you should ensure that it can effectively clamp and fix the cable used based on the material and structural characteristics of the cable.

Cable diameter:

The diameter of the cable is an important factor in determining the specifications of the wire grip pullers. The matching wire grip pullers model should be selected according to the actual cable diameter used to ensure the clamping and tightening effect. At the same time, different models of wire grip pullers usually come with a jaw profile diagram, which can intuitively show the range of cable diameters they are suitable for.

Maximum safe load:

The maximum safe load of the wire grip pullers is another key factor to consider when choosing. Users should choose a wire grip puller that can withstand the corresponding load based on the load requirements in the actual application to ensure the safety of construction and operation. The maximum safe load is usually indicated in the instruction manual for the wire grip pullers, and an embedded jaw profile diagram is attached. Users can refer to this information for selection.

Instructions for use of wire grip puller

During the use of a wire grip puller, the following points are particularly important:

Correctly select the jaws of the wire grip puller:

Different types of cables require different types of jaw designs to prevent damage to the cables. Choosing the right jaws can not only effectively improve operating efficiency, but also reduce the risk of wear and damage to the cables.

Ensure clamping stability:

When fixing and pulling cables, it is necessary to ensure that the jaws of the wire grip puller are long enough to hold the entire strand of cable. This design helps to avoid unnecessary pressure and friction on the cable, thereby extending the service life of the cable.

Follow the operating manual:

Before using the wire grip puller, users should read the operating manual carefully and strictly follow the instructions for installation and operation. Ensure that all parts are intact, and regularly inspect and maintain the wire grip puller to ensure its stability and safety in long-term use.

Why choose HULK Metal as your Wire Grip Puller supplier

Quality

HULK Metal always puts quality first. We are well aware that high-quality products are the cornerstone of winning customer trust. Therefore, we strictly control every detail in the production process to ensure that each batch of products meets the highest quality standards.

Efficient production capacity:

We have first-class production equipment and advanced manufacturing technology, which can efficiently produce various specifications of Wire Rope Gripper to meet the needs of the global market. Our factory is equipped with automated production lines and precision processing equipment, which can quickly respond to customer orders and ensure on-time delivery.

Strict quality control:

We have established a complete quality control system covering all aspects such as raw material procurement, production and processing, and finished product testing. Each process has a professional quality inspection team to conduct strict inspections to ensure that the dimensional accuracy, strength, and durability of the product meet customer requirements. Our products have undergone multiple tests, including load tests, fatigue tests, and corrosion resistance tests, to ensure their reliability and safety under various working conditions.

Comprehensive customization services:

We understand that different customers may have different requirements for Wire Grip Puller. To this end, we provide a full range of customization services and can design and produce customized products according to the special needs of customers. Whether it is the product specifications and dimensions, material selection, or surface treatment and packaging methods, we can provide professional solutions to meet the personalized needs of customers.

Brand

HULK Metal is not only committed to producing high-quality products but also pays attention to brand building and sustainable development. Our brand represents quality, innovation, and excellent customer service.

Strict quality management system:

HULK Metal has passed ISO9001, ISO14001, and ISO45001 quality management system certification, which means that our product production and management processes are in line with international standards. In terms of quality management, we strictly follow the requirements of ISO9001 to ensure that every product undergoes rigorous quality testing and meets internationally recognized quality standards. At the same time, we also follow the requirements of ISO14001 environmental management system and are committed to environmentally friendly production and reducing the impact on the environment.

Continuous technological innovation:

We always regard technological innovation as the core driving force for corporate development. The company has a team of industry experts dedicated to the development of new products and the optimization and upgrading of existing products. We continue to introduce advanced production equipment and technical processes to improve the performance and quality of our products.

Customer-oriented service concept:

We always adhere to the customer-centric service concept. Whether it is pre-sales product consultation or after-sales technical support, we provide customers with timely, professional, and thoughtful services. We have an experienced customer service team, online 24 hours a day, ready to answer customers' questions and provide customers with the most suitable solutions.

As a key tensioning and fixing tool, the wire grip puller is widely used in various cable construction and maintenance scenarios. Its high-strength alloy steel material, advanced heat treatment process, unique clamping design, and diversified specification selection enable it to adapt to cables of different types and sizes and perform well under various working conditions. When selecting and using the wire rope puller, users should fully consider factors such as the type, diameter, and maximum safe load of the cable to ensure that the selected product can meet actual needs, and strictly abide by the instructions for use and safe operating specifications to ensure the smooth progress of construction and the safety of operators.

Article Navigation

Article Navigation

Industries

Forging Factory

-

012024.07Difference between hot forging and cold forging

012024.07Difference between hot forging and cold forging -

272024.06What are the advantages and disadvantages of the hot forging process?

272024.06What are the advantages and disadvantages of the hot forging process? -

182024.01Forging: What Is It? What Are The Different Types of Hot Forging?

182024.01Forging: What Is It? What Are The Different Types of Hot Forging? -

252024.07How to Choose the Perfect Cable Grips for Your Needs?

252024.07How to Choose the Perfect Cable Grips for Your Needs? -

032024.07What are the processes of hot forging?

032024.07What are the processes of hot forging?