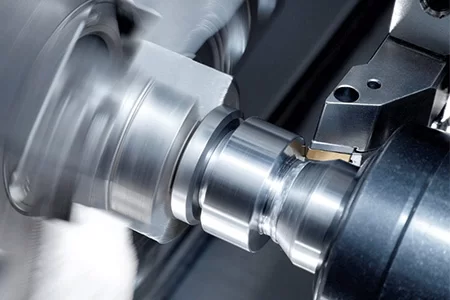

HULK Metal's main processing equipment is CNC machining center and CNC lathe. We have various advanced processing equipment,turning, milling machines, grinders, drilling machines and advanced CNC machining centers.

HULK Metal

Precision Machining Forgings Services

-

Capacities

-

Industries

-

Introduction

-

Factory

-

Benefits

-

Process

-

Articles

-

Review

-

Top

MACHINING FORGINGS SERVICES CAPACITIES

Here, we will introduce our forging processing service capabilities from surface roughness, technology, materials, machining centers, quality control, and other aspects. Kindly contact our engineers if you want to get more information.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Carbon Steel, Alloy Steel,Stainless Steel |

PROCESS: | Turning, Milling, Grinding, Drilling, Reaming, Tapping, Polishing, And So On. |

WEIGHT: | <=50kg/piece |

PRODUCTION CAPACITY: | 1000 tons/month |

CERTIFICATION: | ISO 9001, DB34/T 1240-2010 etc. |

TOLERANCE LEVEL: | Min IT5, According to CNC Machining Process. |

SURFACE ROUGHNESS: | RA>=0.2µm |

MACHINING CENTER: | Four-axis, Five-axis, Three-axis. |

MOQ: | 500KG / A Standard Tray |

MACHINING FORGINGS INTRODUCTION

Here, we will introduce the content of metal forging processing, what is forging processing, and the types and functions of mechanical processing. The advantages of choosing us as your metal processing supplier will also be covered. If you are looking for a trustworthy supplier, please contact us.

Why Choose Machining Service From HULK Metal

HULK Metal provides a variety of forging processing services with high precision and obvious price advantages. Whether you need personalized customization or mass production, we can meet your needs and ensure quality and delivery time.Once we receive your drawings, our engineers will review them as soon as possible and provide a quote as soon as possible.

-

Factory

We have milling machines, mold machines, drilling machines, lathes, CNC machining centers, wire cutting machines, spark machines and other mold manufacturing equipment. Our CNC machine tools can limit the tolerance to ±0.001mm and can process 5g-50Kg products.

-

Experience

The metal forging services we provide cover multiple industries, including construction hardware, trailer manufacturing, automotive exterior decoration, powerline hardware, fitness equipment and other industries. We cannot disclose the information of customers we have served, but we can develop free solutions according to your requirements. If you are satisfied, we will cooperate again.

-

Quality

We have a strict quality inspection process. From raw material inspection to final product inspection, we strictly control every link and are committed to providing customers with high-quality forging products. Quality is our core value. We are committed to providing customers with excellent metal products. Forging processing solutions.

-

Service

Our metal forging services include but are not limited to: engineering design, material selection, mold making, processing and production, quality control and timely logistics and distribution. Whether you need custom parts, prototyping or mass production, we can provide you with high-quality, efficient solutions.

MACHINING PROCESSES OF YOUR FORGINGS

Here, we will introduce you to the basic process of the machining stage of formed forgings. Common machining operations include turning, milling, drilling, etc. When performing mechanical processing, select appropriate tools and processing parameters according to product requirements, and strictly control processing quality and accuracy to ensure that the size and performance of forgings meet the requirements.

-

01Forging Blank

01Forging BlankThe size of the blank processing allowance and tolerance directly affects the labor volume of mechanical processing and the consumption of raw materials, thereby affecting the manufacturing cost of the product.

-

02Choose the Right Machine Tool

02Choose the Right Machine ToolCombine various processing parts and processing procedures to select appropriate processing equipment. For precision machining of small parts, we recommend a CNC lathe or CNC milling machine to ensure high precision and stability. For the forging of large parts, we are equipped with large CNC lathes and CNC vertical lathes to meet your needs. You can go to the Blog to learn more.

-

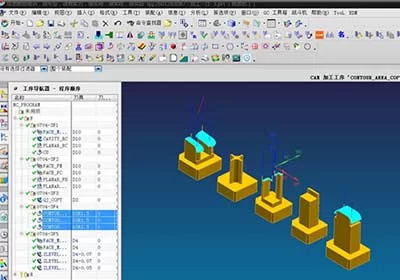

03Design Machining program

03Design Machining programThe parts are accurately designed in CAD software, and CAM software is used to convert the CAD design into a set of machine instructions, which will be communicated to the CNC machine tool.

-

04CNC Machining

04CNC MachiningCNC machines will precisely cut and shape materials according to machine instructions, producing forgings that meet precise specifications through a highly automated and precise machining process.

-

05Quality Control

05Quality ControlWe implement strict dimensional inspection and surface quality inspection, and use advanced measuring equipment and inspection tools to ensure that product size and surface quality meet the requirements.

-

06After Service

06After ServiceOur service commitment goes beyond product quality to include continuous improvement to meet your changing needs. Please feel free to choose us, your satisfaction is our greatest pursuit.