HULK Metal's manufacturing process strictly follows ISO9001:2015 standards to ensure that every product produced, tested and delivered is of high quality. Our dedication to quality can be seen throughout the entire production chain, providing customer

To Supply Higher Quality Forging Parts

HULK Metal Forging QC Center

-

Home>

-

Forging Factory>

-

QC Center>

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

Our quality control center performs quality control on multiple aspects, including production process quality control, raw material quality control, heat treatment quality control, mechanical and chemical composition quality control, non-destructive testing quality control, process inspection quality control, testing and equipment quality control. Through these systematic quality control measures, we ensure that every process meets the highest standards, thereby providing customers with durable and reliable forging products.

HULK METAL QC CENTER EQUIPMENT

Our quality control center is equipped with state-of-the-art equipment and instruments to ensure product quality meets the highest standards. These include advanced three-dimensional coordinate measuring machines, hardness testers, metallographic microscopes, etc. If you have further information about our equipment and quality control processes, please contact our sales manager.

-

01CMM

The size and shape of the forgings can be accurately measured to ensure it meets the design requirements.

-

02Hardness Tester

Evaluate the hardness and strength of the forgings to ensure its reliability and durability in use.

-

03Electron Microscope

Check the microstructure of the forging to ensure its quality is intact.

-

04Spectrograph

Detect the types and contents of elements in forgings.

-

05Salt Spray Test Machine

Simulate salt spray environmental conditions to assess the salt spray corrosion resistance quality of forgings.

-

06Impact Tester

Test the impact resistance of forgings when subjected to impact.

-

07Tensile Testing Machine

The tensile, fracture, compression, bending, shearing, bending resistance and other properties of forgings can be tested through various experiments.

QUALITY CONTROL CENTER TESTING MOMENT

Here, we show the moment when the quality inspector inspects the product. We know that product quality is very important to our customers, so we ensure that every product has passed the most stringent inspection. You can contact our sales manager to learn more.

-

Corrosion and Oxidation Resistance Testing

Use a salt spray testing machine to simulate the use environment to test the corrosion resistance and oxidation resistance of the castings or surface treatment.

-

Casting Dimensional Inspection

Use a CMM measuring machine to test whether the product size and shape are qualified.

-

Metallographic Testing

Quality inspectors operate electron microscopes to examine the internal structure of metal.

-

Hardness Testing

Use Rockwell or Brinell hardness tester to test the wear resistance of castings.

-

Tension Testing

Use a tensile testing machine to test the tensile strength, fracture resistance, yield resistance, and other capabilities of castings.

HOW HULK METAL QC CENTER TEST YOUR ORDER

Through strict random inspection or comprehensive testing methods, we ensure that each forging meets the standards. Quality inspection is carried out from raw materials, semi-finished products and finished products. The general quality inspection of forgings includes: chemical composition inspection, appearance dimension inspection, macrostructure inspection, microstructure inspection, mechanical performance inspection, residual stress inspection and ultrasonic flaw detection, etc.

-

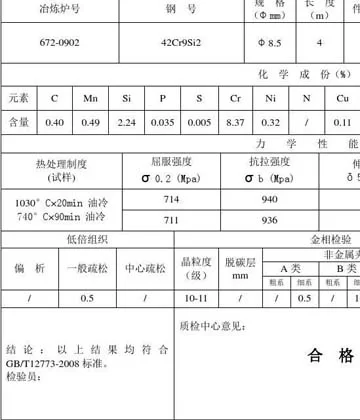

PART 01Raw Material Testing and Report

PART 01Raw Material Testing and ReportEach batch of raw materials we purchase will have a quality inspection report to ensure that all raw materials meet standards.

-

PART 02Heat Treatment Testing

PART 02Heat Treatment TestingEach batch of heat-treated forgings will have a heat treatment report, providing reliable guarantee for the subsequent use of the forgings.

-

PART 03Surface Treatment Testing

PART 03Surface Treatment TestingAfter surface treatment, the forgings are subjected to visual inspection, touch inspection, coating thickness measurement, surface roughness inspection, etc.

-

PART 04Finished Forgings Testing

PART 04Finished Forgings TestingTest its shape, tolerances, final mechanical properties, surface accuracy, chemical properties, etc.

-

PART 05Goods Quantity Testing

PART 05Goods Quantity TestingThe result obtained by dividing the net weight by the unit weight needs to be greater than the quantity of goods.

-

PART 06Pre-delivery Testing

PART 06Pre-delivery TestingWe will unpack the products again to randomly check the quality and recalculate the quantity to ensure that customers receive goods with guaranteed quality and quantity.

PARTS HULK METAL HAVE PRODUCED

HULK Metal provides high-quality metal forgings to many industries including construction hardware, trailer manufacturing, automotive exterior decoration, powerline hardware, fitness equipment, and many more.Choosing HULK Metal means choosing reliable, efficient and high-quality solutions. If you also need OEM service, please feel free to contact us.

-

ACSR Cable Conductor Gripper

ACSR Cable Conductor GripperA Cable Conductor Gripper is an essential tool designed for use with steel wire, Aluminum Conductor Steel Reinforced (ACSR) wire, or insulated wire. This versatile product is engineered to meet a wide range of applications.

READ MORE

-

Wire Rope Gripper For Bare Aluminum

Wire Rope Gripper For Bare AluminumA Wire Rope Gripper is an essential mechanical component engineered to secure and stabilize steel or aluminum wire ropes, ensuring their safe and reliable use across various applications.

READ MORE

-

Steel Cable Grips

Steel Cable GripsSteel Cable Grips are made of high-strength seamless steel pipes. They are formed by hot die forging and undergo strict quenching and tempering. They have many superior properties.

READ MORE

-

Trailer Spare Parts

Trailer Spare PartsHULK Metal is committed to providing you with a variety of trailer spare parts to meet your diverse needs and application scenarios. Our extensive product line includes but is not limited to, hitches, brackets, wheels, braking systems, and connectors.

READ MORE

-

Shackle Hitch Receiver

Shackle Hitch ReceiverHULK Metal's shackles are made of high-quality carbon steel, alloy steel, and stainless steel, with a safety factor of 4 to 6 times. A variety of specifications are available for you to choose from, and non-standard customization is supported.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesOur lifting devices are carefully designed to solve situations where the load is too heavy to be lifted manually, or where the load needs to be lifted regularly and manual lifting would cause unnecessary stress to the operator.

READ MORE

More Results

CHOOSE HULK METAL CASTING YOU WILL GET

When choosing an excellent hot forging factory, you need to comprehensively consider the factory's experience, quality control, service, price, etc. HULK Metal has more than 20 years of hot forging experience, strict quality control, perfect service, and competitive prices , please feel free to choose us.

-

Get Higher Quality Forgings

We strictly implement the ISO 9001 quality management system to ensure the rigor and consistency of the product manufacturing process and continuously improve product quality and customer satisfaction.

-

Get Goods Faster

The optimized production process and meticulous management of each production link effectively shorten the rated production cycle and ensure the dual improvement of production efficiency and product quality.

-

Spend Less Money

We optimize supply chain management, purchase raw materials in a timely manner, improve production processes, and complete delivery faster. We have long-term cooperation with international logistics and can deliver goods to you as quickly as possible.

-

Spend Less Time & Energy

Our sales manager will lead a service team including technology, procurement, production, quality inspection, freight consulting, and other personnel to help you solve various problems during the order process, helping you save more time and energy.

ARTICLES OF METAL FORGING

We have compiled a lot of metal forging articles. You can fully understand all kinds of knowledge when needed. Kindly send a drawing to us when you need a metal forging service. And Our sales manager will give you suitable solutions and better quotations.

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

July 03, 2024

What are the processes of hot forging?

READ MORE