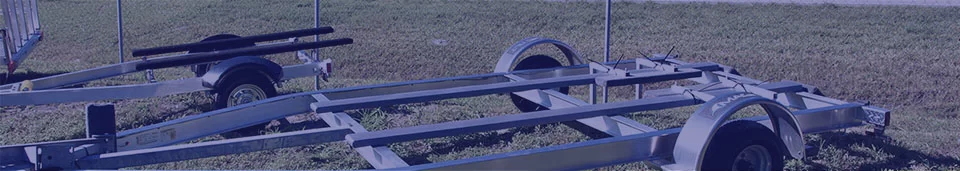

We specialize in the production of various trailer forgings and are committed to providing customers with high-quality, durable and excellent-performance trailer spare parts. Our products, including but not limited to towing hooks, connectors, support rod

HULK Metal Supply Better

Trailer Spare Parts

Industries

-

- Jaw Wire Puller

- Wire Rope Cable Puller Grippers

- Wire Grips

- GFB Type 9 Ton Parallel Jaw Grip

- Cable & Wire Grip 3.63 Ton Puller 8000lbs Rope Size 7mm - 20mm

- GTB Type 5.44 ton L Cable Installation Tools Wire Gripper

- GTA Type 2.0 Ton-5.44 Ton Steel Wire Rope Clamp, Wire Or Cable Grip, Come Along Clamp

- GJA Type 3.63 Ton Grip with Swing Latch

- GTC Type 20KN Wire Grip For For Bare Copper Cable, Covered Cable, Guy Wire

- Wire Rope Gripper

- Wire Grips for High Strength Cables

- Wire Grips For Covered Conductor

- ABC Conductor Grips

- ACSR Cable Conductor Gripper

- Wire Rope Gripper For Bare Aluminum

- Wire Grips For Wire Rope

- Wire Grips For Guy Wire

- Cable Grips For Copper Cable

- Steel Cable Grips

- Wire Cable Grips

- Cable Grip Puller

- Wire Rope Grip

- Wire Grip OEM Service

-

Features

-

Capacities

-

Description

-

Factories visit

-

Benefits

-

Articles

-

Review

-

Top