HULK Metal will continuously update the dynamics of the metal products industry, to support your decision-making.

Hulk Metal News

Share what's new

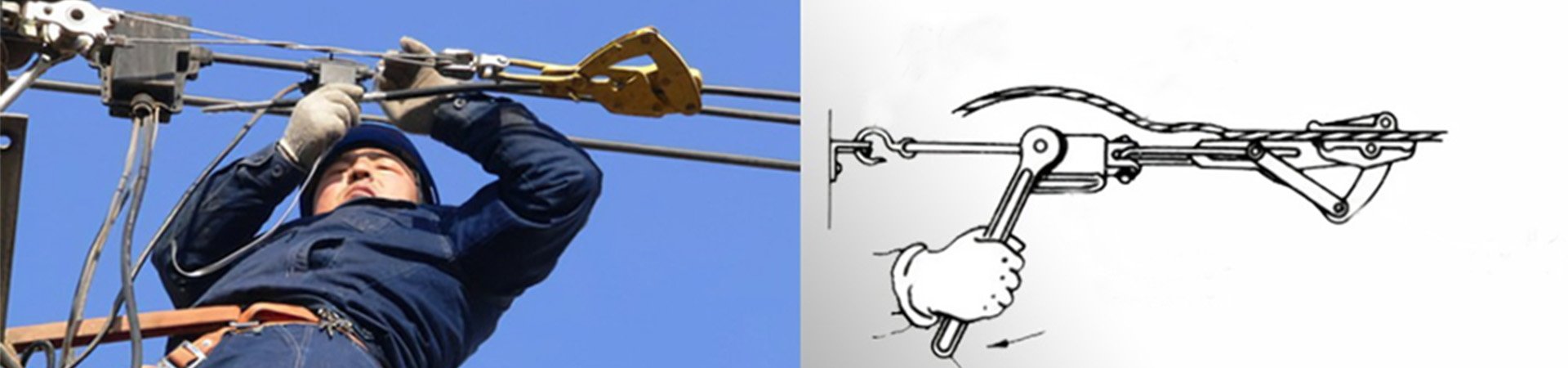

Wire Cable Grips: Types, Mechanisms, and Applications

Cable grips, also known as wire grips or come-along, are essential tools in the construction, maintenance, and inspection of various cable and wire systems. These devices are designed to meet the specific demands of different industries and wire specifications, providing standardized and efficient operational solutions. The diverse range of cable grips available in the market today is a testament to the versatility and innovation in this field, ensuring that there is a suitable grip for virtually every application.

Types of Wire Cable Grips

Aluminum Alloy Conductor Grips

Aluminum alloy conductor grips are specifically designed for holding aluminum alloy conductors. These grips are lightweight yet robust, providing a secure hold without damaging the conductor. They are widely used in industries where aluminum conductors are prevalent, ensuring safe and efficient handling.

Insulated Conductor Grips

Insulated conductor grips are designed for gripping insulated conductors. These grips ensure that the insulation is not damaged during the gripping process, which is crucial for maintaining the integrity and safety of the electrical system. They are essential tools in the electrical and telecommunications industries.

Steel Strand Grips

Steel strand grips are used for gripping steel strands. These grips are built to handle the high tensile strength of steel wires, making them indispensable in industries such as construction, where steel cables are commonly used for structural support and lifting operations.

Ground Wire Grips

Ground wire grips are specially designed for operations involving ground wires. These grips ensure a firm hold on the ground wire, which is essential for maintaining electrical safety and preventing accidents. They are widely used in electrical installations and maintenance.

Single Cam Grips

With a robust construction and precision-engineered cam mechanism, Single Cam Grips ensure a firm grip on cables of various diameters.

Double Cam Grips

Featuring two cam mechanisms, these grips provide a more balanced and secure hold, reducing the risk of slippage. They are especially useful for larger and heavier cables, ensuring safe and efficient operations.

Frog Grips

Frog Grips are commonly used in sectors such as event management, entertainment, and temporary power distribution where time and efficiency are crucial.

Anti-Twist Steel Wire Rope Grips

Anti-twist steel Wire Rope Grips are indispensable for operations requiring the prevention of cable twisting and tangling.

Mechanism of Wire Cable Grips

The mechanism of wire cable grips involves a carefully designed system that provides a secure hold on the wire or cable while allowing for easy release when needed. Most wire cable grips operate on the principle of friction, where the grip's jaws clamp down on the cable, increasing the holding power as the tension on the cable increases. This self-tightening mechanism ensures that the grip remains secure under load but can be easily released when the tension is reduced.

The design of the jaws and the material used in the construction of the grips are critical factors that determine their effectiveness. High-quality wire cable grips are made from durable materials such as high-strength steel or aluminum alloy, ensuring longevity and reliable performance under various working conditions.

Applications of Wire Cable Grips

Wire cable grips are used in a wide range of industries and applications, reflecting their versatility and essential role in modern industrial operations. Some of the primary application areas include:

Ports

In port operations, wire cable grips are used for securing and handling heavy cargo, ensuring safe and efficient loading and unloading processes.

Power Industry

Wire cable grips are crucial in the installation and maintenance of electrical power lines, providing secure holds on conductors and ground wires.

Steel Industry

The steel industry relies on cable grips for handling steel wires and cables, which are integral to various manufacturing and construction processes.

Shipbuilding

In shipbuilding, wire cable grips are used for handling steel cables and wires during the construction and maintenance of ships, ensuring precision and safety.

Petrochemical Industry

The petrochemical industry uses wire cable grips for various applications, including the installation and maintenance of pipelines and other infrastructure.

Mining

In mining operations, wire cable grips are essential for handling cables used in lifting and transporting materials, ensuring safety and efficiency.

Railways

Railway construction and maintenance involve the use of wire cable grips for securing and handling cables and wires, contributing to the stability and safety of railway systems.

Construction

The construction industry extensively uses wire cable grips for various applications, including lifting and securing materials, ensuring safe and efficient building processes.

Metallurgical and Chemical Industries

These industries rely on wire cable grips for handling cables and wires used in various manufacturing processes, ensuring precise and safe operations.

Automotive Manufacturing

Wire cable grips are used in the automotive industry for handling cables and wires during the manufacturing and assembly of vehicles.

Plastic Machinery

In the plastic machinery industry, wire cable grips are used for handling wires and cables involved in the manufacturing process, ensuring smooth operations.

Industrial Control

Wire cable grips are essential in industrial control systems, providing secure holds on control cables and wires, ensuring reliable performance.

Highways

Wire cable grips are used in highway construction and maintenance for handling cables used in various infrastructure projects.

Heavy Transport

In heavy transport operations,wire cable grips are used for securing heavy loads, ensuring safe and efficient transport.

Pipeline Installation

Wire cable grips play a crucial role in the installation and maintenance of pipelines, ensuring secure handling of pipes and cables.

Slope and Tunnel Construction

In slope and tunnel construction,wire cable grips are used for securing cables and wires, ensuring safe and efficient operations.

Shaft Governance and Protection

Wire cable grips are used in the governance and protection of shafts, providing secure holds on cables used in these operations.

Offshore Rescue

In offshore rescue operations, wire cable grips are used for handling rescue cables, ensuring secure and efficient rescue processes.

Ocean Engineering

Ocean engineering projects involve the use of wire cable grips for handling cables and wires used in various marine applications.

Airport Construction

In airport construction, wire cable grips are used for handling cables and wires involved in the construction process, ensuring safe and efficient operations.

Bridges

Wire cable grips are essential in bridge construction and maintenance, providing secure holds on cables used in these structures.

Aviation and Aerospace

The aviation and aerospace industries use wire cable grips for handling cables and wires involved in the manufacturing and maintenance of aircraft and spacecraft.

Venues

In venues such as stadiums and arenas, wire cable grips are used for securing cables involved in various installations and maintenance operations.

How to Choosing a Wire Cable Grips Supplier

Selecting the right wire cable grips supplier is crucial for ensuring the quality and reliability of the products you use in your operations. Here are some key factors to consider when choosing a supplier:

Quality and Certification

Ensure that the supplier provides high-quality wire cable grips that meet industry standards and certifications. Look for suppliers with a proven track record of delivering reliable and durable products.

Product Range

Choose a supplier that offers a wide range of wire cable grips to meet different needs and applications. A diverse product range indicates the supplier's capability to cater to various industrial requirements.

Customization

Consider suppliers that offer customization options for wire cable grips. This allows you to get products that are tailored to your specific needs and applications.

Technical Support

A good supplier should provide excellent technical support and customer service. This includes offering guidance on product selection, installation, and maintenance.

Price and Value

While price is an important factor, it should not be the sole consideration. Evaluate the overall value provided by the supplier, including product quality, durability, and support services.

Reputation

Research the supplier's reputation in the industry. Look for reviews and testimonials from other customers to gauge the supplier's reliability and customer satisfaction levels.

Lead Time and Delivery

Ensure that the supplier can meet your delivery timelines and provide timely and efficient shipping services. This is crucial for maintaining your project schedules and avoiding delays.

After-Sales Service

Consider the after-sales service provided by the supplier. This includes warranty, repair, and replacement services, which are important for ensuring the long-term performance of the wire cable grips.

Wire cable grips are indispensable tools in a wide range of industries, providing secure and efficient handling of cables and wires. Understanding the different types of wire cable grips and their specific applications is essential for selecting the right products for your needs. Additionally, choosing a reliable and reputable supplier is crucial for ensuring the quality and performance of the wire cable grips you use. By considering factors such as quality, product range, customization options, technical support, price, reputation, lead time, and after-sales service, you can make an informed decision and ensure the success of your projects.

Article Navigation

Article Navigation

Industries

Forging Factory