HULK Metal will continuously update the dynamics of the metal products industry, to support your decision-making.

Hulk Metal News

Share what's new

-

Home>

-

Blog>

-

Technology>

What are the models of wire grip and their different usage scenarios?

As a core tool in power engineering construction, communication network construction, and railway electrification transmission line engineering, wire grip plays an irreplaceable role. It realizes efficient adjustment and fixation of transmission lines through precise gripping and clamping functions, thereby improving construction efficiency and operation safety. According to different application loads and cable types, wire grip is subdivided into many types, including aluminum alloy profile transmission line wire grip, insulated layer transmission line wire grip, steel hinge wire grip, ground wire wire grip, single peach wire grip, double peach wire grip, frog wire grip and anti-twist galvanized steel wire rope wire grip. The following is a detailed description of various types of wire grips and their main uses, characteristics, and applicable scenarios.

Aluminum alloy profile transmission line wire grip

Main use

Aluminum alloy profile transmission line wire grip is mainly used for sag adjustment of overhead transmission lines and tightening of transmission lines. It plays a key role in the construction and maintenance of transmission lines.

Product Features

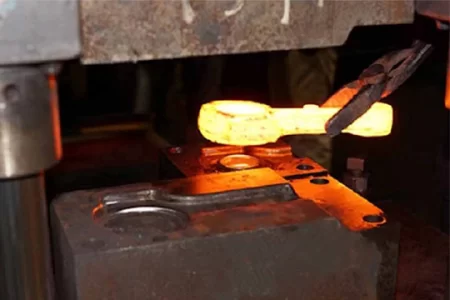

1. High-strength material: Made of high-toughness titanium-magnesium-aluminum alloy material, it is formed by a precision die forging process and has excellent strength and durability.

2. Lightweight design: Compared with traditional materials, it is lighter and easier for construction workers to carry and operate.

3. Wide range of applications: Applicable to aluminum stranded wire and steel core aluminum stranded wire, it can meet the needs of various overhead transmission lines.

Advantages

Due to the use of high-strength and lightweight materials, the aluminum alloy profile transmission line wire grip can reduce the labor intensity of construction workers while ensuring gripping force, and is particularly suitable for long-term and high-frequency operation scenarios.

Steel hinge wire grip

Main use

The steel hinge wire grip is specially designed for steel hinge wire and is commonly used in railway electrification transmission lines, ground wire adjustment, and wire tightening operations.

Product Features

1. Excellent wear resistance: Special alloy steel materials are selected and have undergone advanced quenching and tempering treatment, which has high wear resistance and fatigue resistance.

2. Precise grip: The jaw design is optimized to remain stable under high tension and is not easy to slip.

3. Safety device: Some models are equipped with a safety lock to prevent the steel hinge wire from falling off, which improves the reliability of operation.

Application scenarios

Suitable for large-span, high-tension transmission line construction, and ground wire adjustment, especially in harsh environments.

Insulated layer transmission line wire grip

Main use

The insulated layer transmission line wire grip is specially designed for transmission lines with insulation layers and is widely used in the construction and maintenance of power communication lines.

Product Features

1. Protect the insulation layer: The jaws are specially designed to effectively avoid damage to the cable insulation layer.

2. Multi-functional adaptation: Suitable for insulated wires of various specifications, flexible and convenient operation.

3. Strong anti-slip ability: Even in bad weather such as rain and snow, it can still maintain a reliable grip.

Application scenarios

It is particularly common in telecommunications and distribution network construction, especially suitable for municipal construction and high-voltage line maintenance projects.

Ground wire grip

Main use

The ground wire grip is used for ground wire adjustment and tightening operations in overhead transmission lines.

Product Features

1. High strength and durability: Made of high-quality carbon steel, it has extremely high strength and corrosion resistance after heat treatment.

2. Applicable to a variety of ground wires: The design is compatible with a variety of specifications of ground wires and has strong adaptability.

3. Lightweight design: moderate weight, convenient for long-distance construction in the field.

Application scenarios

Widely used in the construction and maintenance of grounding systems of power lines, especially in high-intensity working environments.

Shuangtao wire grip

Main use

Shuangtao wire grip is suitable for adjusting the suspension wire of suspension towers and tightening the grounding wire.

Product Features

1. Strong flexibility: simple design and easy operation, suitable for multi-angle operations.

2. High durability: high-quality steel is used and heat-treated to extend the service life.

3. High safety: equipped with anti-slip design and additional fixing devices to ensure the stability of construction.

Application scenarios

Commonly used in construction, railway electrification, and transmission line installation, it is especially suitable for working needs under complex terrain conditions.

Frog wire grip

Main use

Frog wire grip is suitable for gripping and adjusting steel-core aluminum stranded wire and multi-strand wire.

Product Features

1. Unique structure: the jaw design simulates the opening of a frog and has super gripping power.

2. High safety: equipped with additional anti-slip devices to avoid accidental loosening.

3. High load-bearing capacity: It can withstand large tension and is suitable for heavy-load construction environments.

Application scenarios

It is mainly used for the installation and adjustment of high-load transmission lines, especially cross-river and cross-mountain transmission projects.

Anti-twist galvanized wire rope wire grip

Main use

Anti-twist galvanized wire rope wire grip is specially designed for galvanized wire rope and is widely used in the construction and maintenance of high-tension transmission lines.

Product Features

1. Anti-twist design: It can effectively avoid the twisting and deformation of the wire rope under high tension conditions.

2. High corrosion resistance: The surface is galvanized to maintain stable performance in harsh environments.

3. Multi-specification compatibility: It is suitable for galvanized wire ropes of various specifications to meet different construction needs.

Application scenarios

It is suitable for coastal power transmission lines, high-humidity areas, and other harsh construction environments.

Universal wire grip

Main use

The universal wire grip is suitable for gripping and fixing wires of various specifications. It is a universal tool.

Product Features

1. High-quality material: It is made of high-strength carbon steel, formed by precision die forging and tempering treatment, and has excellent tensile strength and durability.

2. Safety device: The jaws are equipped with a special anti-slip safety device to prevent the cable from accidentally slipping off.

3. Versatility: It can adapt to a variety of cable types and is flexible and easy to operate.

Application Scenarios

It is widely used in the comprehensive construction of power, communication, and railway electrification projects, and is suitable for various complex conditions.

HULK Metal's customized service

HULK Metal has more than a dozen existing wire grip molds, which can produce wire grip products of various specifications to meet the needs of conventional projects. At the same time, we support customized production according to the drawings provided by customers to ensure that the products fully meet the technical requirements and application scenarios of specific projects.

As an important tool in industries such as power, communication, and railways, wire grip provides efficient and safe support for the construction and maintenance of transmission lines through continuous technological innovation and process optimization. Whether in terms of lightweight design, durability improvement,t or safety performance optimization, various types of wire grips reflect the comprehensive upgrade of technology and functions. In the future, the application scope of wire grip will be wider, and its performance will be further improved, providing strong support for construction projects in more fields.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE