HULK Metal will continuously update the dynamics of the metal products industry, to support your decision-making.

Hulk Metal News

Share what's new

-

Home>

-

Blog>

-

Technology>

Features and Applications of Universal Wire Cable Pulling Grip

Application areas

Universal Wire Cable Pulling Grip is an indispensable tool in the field of power and communications. It is widely used in the construction of overhead transmission lines, and is especially suitable for tightening and pulling of insulated conductors and steel core aluminum stranded wires. Its main function is to stretch, fix and tighten the wires by clamping them to ensure the safety and efficiency of line installation.

Applicable objects

·Insulated wires: These wires are covered with an insulating layer and are often used in urban distribution networks to improve safety and reduce power losses.

·Aluminum core steel stranded wire (ACSR): This type of conductor is made of aluminum wire stranded on a galvanized steel core wire. It combines the good conductivity of aluminum with the high strength of steel. It is widely used in long-distance, high-voltage power transmission lines.

Materials and manufacturing processes

A high-quality Universal Wire Cable Pulling Grip is usually made of high-toughness forged carbon steel and undergoes the following treatment process:

Material properties

·High-toughness carbon steel: Carbon steel is known for its excellent mechanical properties. After forging and heat treatment, it has high strength, tensile resistance, and impact resistance.

·Colored zinc plating treatment: By plating a layer of colored zinc on the surface of the steel, it not only gives the product higher corrosion resistance, but also enhances its aesthetics.

Production process

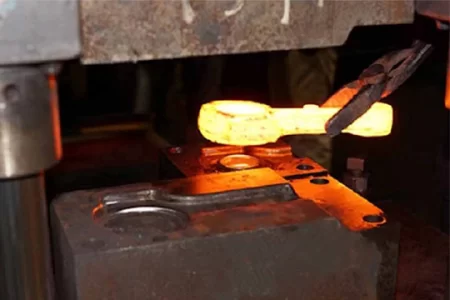

1. Forging process: Precision forging technology is used to ensure uniform material structure, reduce internal defects, and improve mechanical properties.

2. High-temperature quenching and tempering treatment: The hardness and toughness of the steel are improved through high-temperature heating and rapid cooling, so that the Wire Cable Pulling Grip can withstand high-load working environments.

3. Surface treatment: Wire Cable Pulling Grip after color galvanization has good weather resistance and anti-oxidation properties, and can adapt to various harsh construction environments.

Features

Lightweight and portable

The wire cable pulling grip is compact in design, light in weight, easy to carry and operate, and can be used flexibly even in small construction sites. This portability greatly improves construction efficiency, especially in high-altitude operations or complex environments.

High strength

Forged from high-strength carbon steel and subjected to special heat treatment, the Wire Cable Pulling Grip has excellent tensile strength and durability. It can maintain its reliable performance regardless of high load or long time operation.

Multifunctional jaw design

The jaws of the Universal Wire Cable Pulling Grip are designed to be sophisticated and diverse:

·Half-moon clamping jaw: used to tighten steel strands and wire ropes to provide stable clamping force.

·Platform clamping jaw: suitable for tightening cables to avoid clamping damage to the cable surface.

Anti-jump safety device

The jaws are equipped with an anti-jumping device, which effectively prevents wires from slipping during construction and ensures safe operation. This design is particularly suitable for high-voltage line construction, reducing the risk of accidental disconnection.

Minimal wire damage

The jaws of the Wire Cable Pulling Grip are finely ground and processed, causing minimal damage to the wires. For insulated conductors and steel core aluminum stranded conductors, clamps can maintain the integrity of the conductors and extend their service life.

Application examples

Overhead transmission line construction

In overhead transmission line construction, Universal Wire Cable Pulling Grip is widely used in the following operations:

·Wire tensioning: Wire Cable Pulling Grip ensures that the sag of the wire meets the design requirements by clamping the wire and applying tension.

·Wire pulling: During the wire laying process, the Wire Cable Pulling Grip is used to fix and pull the wire to ensure that the wire is laid along the intended path.

Urban distribution network transformation

Insulated conductors in urban distribution networks require higher construction accuracy and safety. Universal Wire Cable Pulling Grip provides construction teams with a reliable solution due to its lightweight and high efficiency.

Long-distance transmission line maintenance

For the maintenance and replacement of steel core aluminum stranded wires, Universal Wire Cable Pulling Grip provides a solid guarantee for construction with its high strength and multifunctional design.

Precautions for use

In order to ensure the safety of construction and the service life of the Wire Cable Pulling Grip, the following matters should be paid attention to:

Product selection

According to the type and diameter of the wire, select the matching Wire Cable Pulling Grip to ensure a firm grip and avoid damaging the wire. For example, a Wire Cable Pulling Grip with flat-type clamping jaws should be used for insulated conductors, while a half-moon Wire Cable Pulling Grip should be used for steel stranded wires.

Inspection and maintenance

Before use, the Wire Cable Pulling Grip should be thoroughly inspected to ensure that all parts are intact, especially the jaws and safety devices. After use, the dirt and residue on the surface of the Wire Cable Pulling Grip should be cleaned and lubricated and maintained regularly.

Correct operation

Use the Wire Cable Pulling Grip in accordance with the operating procedures to avoid overload use. When working at heights, safety equipment should be worn to ensure the safety of construction personnel and equipment.

Storage conditions

Clamps should be stored in a dry, ventilated environment to avoid moisture and rust. During long-term storage, a layer of anti-rust oil can be applied to the surface of the Wire Cable Pulling Grip.

Performance testing

Universal Wire Cable Pulling Grip must undergo rigorous performance testing before leaving the factory, including:

Tensile strength test: Verify the reliability of Wire Cable Pulling Grip under high load.

Corrosion resistance test: simulate usage in harsh environments to ensure the durability of the fixture.

Fatigue test: Evaluate the performance stability of the Wire Cable Pulling Grip after repeated use.

Future development trends

With the rapid development of the power and communication industries, the demand for Universal Wire Cable Pulling Grip is also growing. Future R&D and improvement directions include:

·Material upgrade: develop lighter and stronger materials to improve the performance of the clamp.

·Intelligent design: Add sensors and wireless communication modules to achieve real-time monitoring and data recording.

·Multi-functional: Design clamps compatible with multiple wire types to meet different construction needs.

Universal Wire Cable Pulling Grip plays an important role in electrical construction due to its high strength, lightness and multi-functional design. Through the correct selection and use of Universal Wire Cable Pulling Grip, construction efficiency can be improved and the safety and integrity of the wires can be ensured. In the future, with the continuous advancement of technology, Universal Wire Cable Pulling Grip will demonstrate its irreplaceable value in more fields and provide strong support for the development of the power and communications industries.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE