By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Cable Gripper Puller: A powerful tool for overhead line construction and maintenance

Material: The fundamental factor that determines the performance of the cable gripper

Characteristics of alloy steel

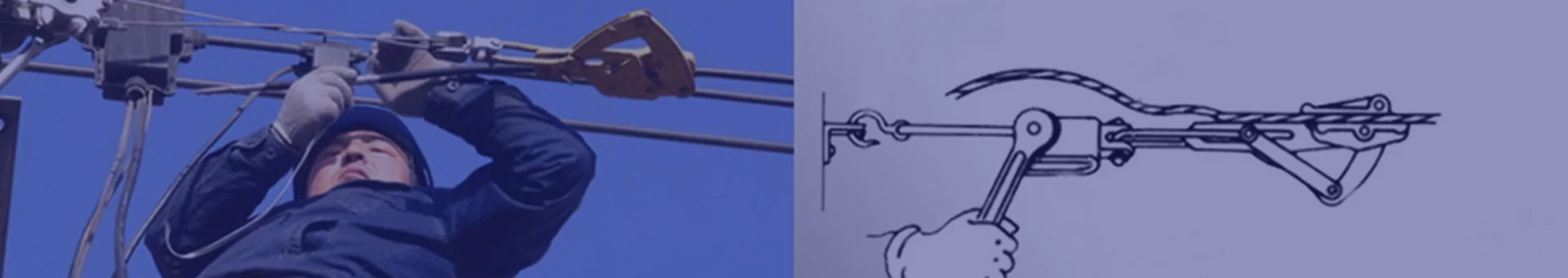

The cable gripper is made of a high-strength steel plate as the main material, with mostly high-quality one-piece alloy steel structure and high-density gears. Alloy steel has excellent mechanical properties. Its high strength and durability can withstand high-strength tension and pressure during overhead line construction and maintenance.

Ability to cope with tension

In the construction of large-scale power overhead lines, such as the construction of transmission lines across mountains or rivers, it is necessary to adjust the sag of the conductor, which requires the cable gripper to withstand huge tension. The cable gripper is made of high-quality alloy steel and can work reliably without deformation or other problems.

Performance in resisting pressure

In some special construction scenarios, such as when conducting line maintenance in areas with complex terrain and a certain drop, the cable gripper may be subject to greater pressure. The structure of alloy steel can withstand this pressure and ensure its own integrity.

The role of high-density gears

High-density gears are not just simple transmission components in cable grippers.

Improve wear resistance

During long-term use, friction will occur between the gears other internal components, and other tool parts. The use of high-density gears significantly improves the wear resistance of the wire clamp, which enables the wire clamp to maintain good working condition after multiple uses and prolongs its service life.

Stable transmission efficiency

High-density gears help maintain stable transmission efficiency during various operations of the wire clamp. Whether tightening the wire or adjusting the position of the wire, it can accurately transmit force to ensure the accuracy of the operation.

Anti-corrosion effect of surface treatment

Alloy steel with proper surface treatment can also resist corrosion factors in the environment.

Adaptability to different construction environments

In humid telecommunication line erection environments, such as in the rainy season in the south or in the construction of communication base stations at the seaside, or in construction scenes around railway electrification lines with certain chemical pollution, such as railway power construction near chemical parks, the corrosion resistance of alloy steel can ensure that the wire clamp is not corroded and ensure the normal use of the tool.

Material advantages of HULK Metal Cable Gripper Pullers as an example

HULK Metal Cable Gripper Pullers use high-quality galvanized steel wire ropes and aluminum alloy pressure heads. This material combination is a reflection of the concept of corrosion resistance. Galvanized steel wire ropes and aluminum alloy pressure heads make the Cable Gripper Pullers wear-resistant, strong and not easy to fall off. In actual operations, especially in complex environments, they can well demonstrate their high-quality performance.

Design: Adapt to different wire diameter requirements

Design features of small-size Cable Gripper Pullers

Small-size Cable Gripper Pullers are specially designed for thin-diameter wires.

Exquisite design structure

The overall structural design is very sophisticated, and it can effectively clamp and operate thin-diameter wires in a limited space.

Adaptability to narrow spaces

In urban telecommunication line reconstruction projects, cables are usually laid in relatively narrow spaces due to the numerous buildings. Small-size Cable Gripper Pullers can be easily operated in this special environment with their precise clamping mechanism, greatly improving construction efficiency.

Design considerations for large-size Cable Gripper Pullers

Large-size Cable Gripper Pullers are designed for thick-diameter wires.

Stronger clamping method

The large-size wire clamp adopts a design that can provide greater clamping force. In railway electrification projects, the wires of the contact network are usually thicker, and the large-size wire clamp can ensure the stable clamping of these thick wires.

Guarantee construction and maintenance work

From the construction process, when installing large-diameter contact network wires, a sufficiently large clamping force is required to ensure the accurate position of the wires; in subsequent maintenance work, such as adjusting or replacing the contact network wires, the large-size wire clamp can also work stably, thereby ensuring the smooth progress of the entire work.

Clamping mechanism: ensuring stable and safe operation

Sawtooth effect to prevent wire sliding

The multi-sawtooth design of the clamping part of the wire clamp plays a key role in preventing the wire from sliding.

Important prevention of safety risks

In the fastening operation of high-altitude power lines, if the clamping force of the wire clamp on the wire is insufficient and causes the wire to slide, it may cause serious safety accidents such as wire falling off or even breaking. The presence of a sawtooth can effectively increase friction, thereby avoiding the occurrence of such dangerous situations.

Uniform force protection for wires

The sawtooth design also makes the clamping force evenly distributed on the wire.

Avoid local damage

When the wire clamp applies clamping force to the wire, if there is no uniform distribution mechanism, it may cause excessive force on a certain part of the wire and cause damage. The structure of the sawtooth allows each part of the wire to be subjected to a relatively balanced force, reducing damage to the wire.

In short, the wire clamp plays an important role in many fields with its unique material, careful design, effective clamping mechanism, and clear model identification. As long as it is used properly, it can provide a reliable guarantee for the construction and maintenance work related to overhead lines.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE