By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Cable Grab in Power and Industrial Applications: Technology, Advantages and Future Development

The close connection between the power industry and Cable Grab

The power industry occupies a vital position in the modern national economy. It not only guarantees the energy supply for daily life but also is the basis for the normal operation of all walks of life. With the continuous development of the economy, the demand for the power industry is increasing, especially the installation and maintenance of cable lines have become an important part of the construction of power facilities. In order to ensure the stability and safety of cable lines, equipment for tightening and fixing cables, such as Cable Grab, plays an extremely important role in the entire power engineering.

As an efficient cable tensioning tool, Cable Grab is widely used in power, railway, slope management, pipeline maintenance, and other fields to help engineers easily and safely complete the tightening and fixing of cables. It not only simplifies the operation process but also improves work efficiency and reduces the intensity of manual labor. It is one of the indispensable tools in modern engineering.

The basic principle and structure of Cable Grab

The main function of Cable Grab is to tighten cables or wires and maintain a certain tension through physical force. Its core working principle is to apply uniform and stable tension on the cable so that the cable can be stretched along the predetermined track to eliminate slack or sagging.

Main structure

Cable Grab usually consists of the following key parts:

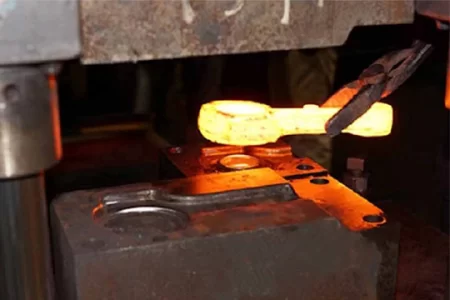

·High-strength alloy steel structure: In order to ensure reliability under high load conditions, Cable Grab is forged with high-strength alloy steel, which has excellent wear resistance and tensile strength.

·Internal card slot pattern design: The design of the embedded card slot enables the cable gripper to firmly grasp the cable and prevent the cable from slipping under high load. The card slot pattern design is a key factor in improving the gripping effect.

·Fastening thread part and ratchet mechanism: The fastening thread part provides stable tension through the ratchet mechanism to ensure that the cable will not loosen during the tightening process and ensure the smooth progress of the construction.

·Gear and reversing hook: These additional components can realize automatic force adjustment during the tightening process and can quickly change direction, further improving the flexibility and convenience of operation.

Working principle

The working principle of Cable Grab is based on the combination of the lever principle and physical friction. When in use, by rotating the fastening thread, the ratchet and gear parts generate sufficient tension to tightly grasp the cable. When the operator is operating, the system will evenly tighten the cable to prevent the cable from sagging or loosening, ensuring that the cable at the construction site is always in a high-tension state.

Application of Cable Grab in the Power Industry

In the power industry, Cable Grab is widely used in the installation and maintenance of cables. The following are some common application scenarios:

Installation of overhead cable lines

When erecting overhead cables, the cables need to be laid along poles or towers. Since cables often have problems such as loosening and sagging during the initial installation, the use of Cable Grab can effectively tighten and fix the cables to ensure the straightness and stability of the line. By using Cable Grab, construction workers can reduce repeated adjustment operations, speed up construction progress, and ensure that the project is completed on time.

Maintenance and repair of power lines

For daily maintenance of power lines, especially when the lines are found to be loose or damaged, Cable Grab can provide strong support to help workers quickly repair the problem lines and avoid accidents such as power outages. In addition, Cable Grab can also effectively reduce the workload of operators and improve work efficiency during the repair process.

Tensioning and installation of high-voltage cables

Due to their special structure and purpose, the installation of high-voltage cables requires very careful tensioning and fixing. Cable Grab has a high-strength alloy steel structure, which can meet the high load requirements of high-voltage cables for tools, ensuring safety and efficiency during the construction process.

Application of Cable Grab in other industries

In addition to the power industry, Cable Grab is also widely used in many other industries. The following are several typical cases:

Railway industry

In the construction and maintenance of railway power equipment, the laying and tensioning of cable lines are also inevitable. The efficiency and reliability of Cable Grab make it one of the most commonly used tools in railway engineering. Especially in the construction of power systems for high-speed railway lines, Cable Grab can quickly and effectively complete the tensioning of cables to ensure the stable operation of the power system.

Slope and pipeline maintenance

Cable Grab can also play an important role in the maintenance of slopes and pipelines. Especially after long-term use, the cable may have problems such as looseness and aging. At this time, it is necessary to use efficient tensioning tools to restore the tension of the cable. Cable Grab not only improves work efficiency in such operations but also effectively ensures the safety of operators.

Water conservancy and communication industry

The construction of water conservancy facilities and the laying of communication cables is also one of the main application areas of Cable Grab. Through the rational use of Cable Grab, the cable laying work can be carried out smoothly, while reducing equipment failures and safety accidents caused by cable loosening.

Technical Advantages of Cable Grab

High strength and durability

Cable Grab uses high-strength alloy steel materials, which gives it super strong tensile strength and can cope with high-load working environments. This allows Cable Grab to maintain good performance after long-term use and has a long service life.

Easy operation and efficiency

The design of Cable Grab takes into account the ease of operation. Even in complex environments, operators can quickly get started and complete work tasks efficiently. In particular, its equipped ratchet and gear structure makes it easy to tighten the cable, greatly saving working time.

Safety and stability

Since the power and high-voltage environment have strict requirements for the safety of the tool, Cable Grab uses multiple safety designs to ensure stability in high-load operations. Its internal card slot design and reversing hook and other details effectively prevent the cable from loosening during the tensioning process, ensuring the safety of the operators.

HULK Metal: Providing you with a better Cable Grab solution

By choosing HULK Metal as your Cable Grab supplier, you will experience a series of advantages. We not only provide customers with high-quality products but also help you achieve significant benefits in many aspects. The following are the four core advantages you can enjoy by cooperating with HULK Metal:

Faster delivery time

In modern engineering projects, time is money. HULK Metal knows this well, so we have optimized the production process and shortened the delivery cycle. Our advanced production equipment and experienced team ensure that every link of the product from order confirmation to production completion to delivery is efficiently executed. Whether you need urgent equipment or customized large-volume orders, we can meet your needs as quickly as possible to ensure that the project is not delayed and avoid the impact of waiting on the construction period.

Higher quality standards

HULK Metal's Cable Grab products use the highest quality materials, such as high-strength alloy steel, combined with exquisite forging technology and strict quality control to ensure that every product meets international quality standards. With an ISO 9001-certified factory, strict quality inspection processes, and comprehensive testing equipment, we ensure that every product shipped out of the factory can withstand various harsh working conditions and loads. We pay attention to every detail and strictly control every step from design to production to ensure the durability and safety of the product.

Save energy and time

With HULK Metal, you don't have to worry about any production and quality issues. Our professional team will provide you with full technical support and after-sales service to help you solve any difficulties in use. You can focus on your core business and leave all the work related to Cable Grab production, quality inspection, and logistics to us. Our delivery is on time and reliable, saving you time and energy wasted due to equipment quality or delivery delays, allowing you to easily cope with the increasingly busy project schedule.

Save money on investment

With HULK Metal, you will get a very cost-effective Cable Grab solution. Our efficient production and optimized supply chain management enable us to offer competitive prices while maintaining high-quality product standards. By purchasing in bulk, you can also enjoy more price discounts. Our products are exquisitely designed, durable, and sturdy, reducing the need for frequent replacement, thereby reducing maintenance costs and replacement fees in long-term use. By choosing HULK Metal, you can not only reduce the initial purchase cost but also achieve cost savings in long-term use.

As an important tool in many fields such as the power industry, railways, and slope maintenance, Cable Grab has become an indispensable tool in modern engineering construction with its high-strength materials, advanced design concepts, and efficient working performance. It not only improves work efficiency and reduces labor intensity, but also ensures the safety of operators through a number of safety designs. With the continuous advancement of technology, the application scope and technical functions of Cable Grab will be more abundant, and it has great potential for application in various industries in the future.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE