By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Alloy Steel Wire Rope Clamp Shipping Introduction: HULK Metal's Efficient Production and Distribution Process

Alloy Steel Wire Rope Clamp is an important tool widely used in various industrial fields, mainly used to ensure the stability and safety of cables or other wires under tension. Whether it is the power, communication, mining, or construction industry, Alloy Steel Wire Rope Clamp plays a vital role. As an industry-leading manufacturer, HULK Metal has become a trusted Alloy Steel Wire Rope Clamp supplier for global customers with years of accumulated experience. This article will introduce HULK Metal's shipping process in detail. From order confirmation to product delivery, each step has been carefully designed to ensure that customers get the best experience.

Order processing: from order receipt to production start

Every order of HULK Metal goes through a strict processing process. From the moment we receive the customer's order, our sales team will immediately communicate with the customer to confirm the order details, including the specifications, quantity, customization requirements, and delivery time of the Alloy Steel Wire Rope Clamp. For customers with special requirements, we also provide customized services to ensure that the product can accurately match customer needs. After the order is confirmed, the production department will schedule the production according to the order requirements, and the procurement team will coordinate the supply of raw materials in a timely manner to ensure the smooth progress of production.

Our production scheduling system is highly intelligent and can prioritize orders according to urgency and production capacity to ensure that all types of products can be delivered on time.

Production process: ensure product quality and efficiency

HULK Metal's production process strictly follows the ISO 9001 quality management system standards. All Alloy Steel Wire Rope Clamp products need to undergo multiple inspections and tests to ensure that their performance and quality meet industry standards. We have advanced production equipment, including 3-axis, 4-axis, and 5-axis milling centers and the latest CNC lathes and turning centers, which provide us with high-precision and high-efficiency production capabilities.

During the production process, we first strictly screen the raw materials and select steel and alloy materials that meet high standards. The manufacturing process of the Alloy Steel Wire Rope Clamp includes multiple processes such as forging, heat treatment, and galvanizing. Each link is equipped with dedicated technicians to control it. Our heat treatment process uses an advanced temperature control system to ensure that each Alloy Steel Wire Rope Clamp achieves the best hardness and toughness.

At the same time, HULK Metal has an experienced quality control team that strictly tests products in accordance with technical standards and customer requirements. Each batch of products needs to undergo multiple tests such as tensile testing and corrosion resistance testing to ensure the safety and reliability of the products in actual use.

Packaging and preparation for shipment: ensuring transportation safety

In order to ensure the safety of the products during transportation, HULK Metal has carefully designed the packaging. We use high-strength, shock-proof packaging materials to provide full protection for each Alloy Steel Wire Rope Clamp. At the same time, the product packaging will clearly mark the relevant transportation requirements and precautions to ensure that the product will not be damaged due to improper operation during transportation.

For bulk orders, we will also use wooden box packaging to ensure the safety of the product during long-distance transportation. In addition, HULK Metal will also add detailed product instructions to the packaging to help customers quickly understand product information after receiving the goods.

Logistics arrangement: efficient service for global delivery

HULK Metal has established long-term cooperative relations with many well-known logistics companies around the world and can provide flexible transportation solutions according to customer needs. No matter which country or region the customer is located in, we can provide fast and stable transportation services to ensure that the products are delivered to the customer in a timely and safe manner.

We support a variety of transportation methods, including sea, air, land, etc. Customers can choose the most suitable method according to their needs. At the same time, our logistics team will track the transportation status of the order in real-time to ensure that each batch of products can be delivered within the scheduled time.

Customer communication and after-sales service: worry-free throughout the process

HULK Metal always insists on maintaining close communication with customers to ensure that customers can keep abreast of the latest progress during order processing, production, and delivery. After the product is shipped, we will immediately send a shipping notice to the customer and provide detailed transportation information to ensure that the customer can grasp the status of the goods in real-time.

If the customer encounters any problems during transportation, our customer service team will provide a quick response and assist in solving any difficulties that may arise. HULK Metal also provides every customer with a complete after-sales service to ensure that customers can smoothly install and use the product after receiving it.

Shipping Examples: Recent Successful Shipping Cases

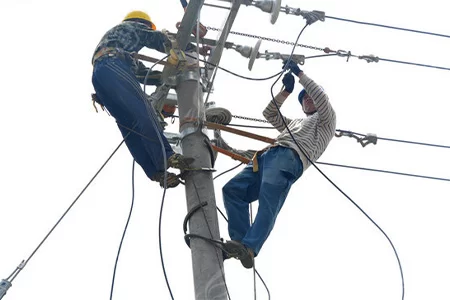

Take the most recent shipment as an example. HULK Metal successfully delivered 5,000 Alloy Steel Wire Rope Clamps to an electric power company in Colombia. The customer of this order required the product to have high tensile performance and corrosion resistance to adapt to harsh environmental conditions. After confirming the order, HULK Metal immediately started the production process to ensure on-time delivery.

During the production process, the quality control team conducted rigorous tensile and corrosion resistance tests on each batch of products to ensure that each Alloy Steel Wire Rope Clamp met the customer's requirements. After the product was packaged, the logistics team arranged for sea transportation and provided customers with real-time transportation tracking information. After receiving the goods, the customer gave high praise to the product quality and delivery service and expressed that he would continue to cooperate with HULK Metal.

HULK Metal has been committed to improving production efficiency and customer experience. From order receipt to delivery completion, every link strives for perfection. In the future, we will continue to optimize the production process, improve the efficiency of logistics services, and further improve customer satisfaction.

We believe that through continuous innovation and improvement, HULK Metal will be able to provide higher quality Alloy Steel Wire Rope Clamps and more efficient delivery services to global customers and consolidate our leading position in the industry.

Article Navigation

Article Navigation

Industries

Foundries

-

December.11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

September.12, 2024

Do you know the comprehensive analysis of wire grip puller?

READ MORE

-

August.27, 2024

Does the operation of wire grips conflict with oil lubrication?

READ MORE

-

February.07, 2025

About HULK Metal Hot Forging

READ MORE

-

January.23, 2025

The difference between forging and casting

READ MORE

-

January.17, 2025

Factors to Consider During Hot Forging Process

READ MORE

-

January.17, 2025

Maintenance of forging dies: ensuring forging life and efficiency

READ MORE