By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

A manufacturer with twenty years of forging experience tells you how to choose a forging factory

Choosing a suitable forging factory is crucial to ensuring product quality, reducing costs, and improving market competitiveness. With twenty years of forging experience, HULK Metal will provide you with comprehensive guidance to help you make an informed choice among many suppliers. The following will provide an in-depth analysis of four aspects: the forging process, key selection factors, environmental protection, sustainable development, and the advantages of HULK Metal.

Overview of the forging process

The definition and importance of forging

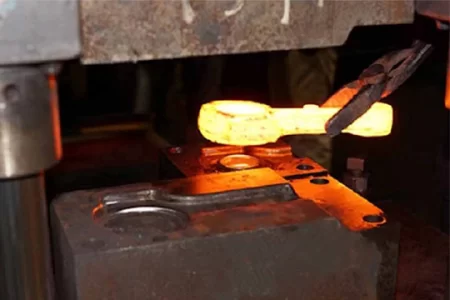

Forging is a manufacturing process that uses equipment such as forging hammers and presses to change the shape and physical properties of metal by applying pressure to it. Because it can significantly improve the density, strength, and toughness of metal materials, it is widely used in aerospace, automotive, engineering machinery, petrochemical, and other industries.

Common types of forging

·Cold forging: Applying pressure to metal at room temperature, suitable for high-precision manufacturing of smaller parts, but requires high material strength.

·Warm forging: It is carried out when the metal reaches a certain temperature but has not completely softened. It combines the high precision of cold forging with the high plasticity of hot forging.

·Hot forging: It is carried out when the metal material reaches above the recrystallization temperature. It is mainly used for the processing of large parts and has a high material utilization rate.

Application of forging in industry

The forging process can produce high-strength, high-durability parts, such as mining machinery parts, trailer parts, and connectors in construction projects. High-quality forged parts can significantly improve the reliability and service life of equipment.

Key factors in choosing a forging factory

technical ability

When choosing a forging factory, you must first evaluate its technical level and equipment capabilities.

· Process level: Advanced precision forging technology can reduce material waste and improve product consistency and precision.

·Advanced equipment: Factories equipped with modern forging hammers, presses, and efficient heating equipment can better ensure production efficiency and product quality.

Quality control

A strict quality control system is the core indicator to measure the reliability of the forging factory.

·Quality management system certification: Such as ISO 9001 certification, which can prove the factory's quality management capabilities.

·Testing methods: such as non-destructive testing, hardness testing, dimensional measurement, etc., which can ensure that the product meets standards in all aspects.

Production capacity

A factory's production capacity determines its ability to meet customer needs.

·Production capacity scale: whether it can support mass production and meet personalized customization needs.

Experience and credibility

Factories that are experienced and reputable tend to be more trustworthy.

·Industry experience: whether you have provided solutions for similar industries or products.

·Customer evaluation: The reliability of the factory can be evaluated through customer cases and partner recommendations.

cost and price

When considering price, focus on transparency and value-added services.

·Pricing strategy: A clear price structure can help customers better control their budget.

·Added value services: such as design optimization, technical support, logistics services, etc., can further enhance the value of cooperation.

Environmental protection and sustainable development of forging factories

As environmental protection requirements become increasingly stringent, choosing a factory with environmental protection capabilities has become an important consideration for many customers.

Environmental protection measures

A high-quality forging factory should be equipped with complete waste gas and wastewater treatment systems and comply with relevant environmental regulations to reduce the impact of production on the environment.

energy efficiency

Advanced equipment usually has higher energy utilization efficiency, which can not only reduce production costs but also reduce carbon emissions, which is in line with the trend of sustainable development.

Sustainability certification

The factory has passed ISO 14001 and other certifications, which shows its professionalism and responsibility in environmental management and is an important manifestation of its social responsibility.

Advantages of HULK Metal

Rich experience

HULK Metal has been deeply involved in the forging industry for 20 years and has accumulated rich technical experience and service cases. We have provided high-quality forged products to customers in the automotive, engineering machinery, construction, and other industries, and have been widely recognized.

advanced technology

·Precision forging technology: Use near-net shape technology to reduce material waste and improve product consistency.

·Modern equipment: Equipped with 3-axis, 4-axis, and 5-axis milling centers and the latest CNC lathes and turning centers to ensure high precision and efficiency in production.

Strict quality control

·Quality certification: passed ISO 9001, CE certification, and TUV, SGS testing.

·Professional testing team: Equipped with advanced testing equipment, we conduct non-destructive testing, hardness testing, etc. on each batch of products to ensure factory quality.

Excellent customer service

·Customized solutions: Tailored according to customer needs, from design to production, participating in optimization throughout the process.

·Professional after-sales team: Provide quick response after-sales service to protect customer interests.

Competitive price

By optimizing production processes and supply chain management, HULK Metal provides market-competitive prices while ensuring high quality, helping customers maintain their advantage in the market.

Choosing the right forging factory has a profound impact on product quality, production efficiency, and corporate competitiveness. You can find the most suitable partner by analyzing factors such as technical capabilities, quality control, production capacity, experience, and reputation, as well as cost and environmental protection.

With twenty years of industry experience, advanced technical equipment, strict quality control, and excellent service capabilities, HULK Metal has become the first choice of many customers. We sincerely invite you to cooperate with us to jointly create high-quality products and achieve win-win development.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE