HULK Metal will continuously update the dynamics of the metal products industry, to support your decision-making.

Hulk Metal News

Share what's new

-

Home>

-

Blog>

-

Technology>

Mining Equipment Spare Parts Forging: the heart of high-quality parts

Mining machinery is one of the core equipment for global resource extraction and transportation. Its operating efficiency and durability directly affect the efficiency of the entire mining process. As the demand for mining continues to increase, the working environment of mining machinery has become more complex and harsh. Therefore, ensuring that the components of mining machinery have extremely high strength, wear resistance, and impact resistance is the key to ensuring the long-term stable operation of mining machinery. Hot forging technology, with its excellent performance, has become an important means of manufacturing mining machinery parts. This article will delve into the hot forging process of mining machinery parts and analyze its importance, technical requirements, and application prospects in mining machinery manufacturing.

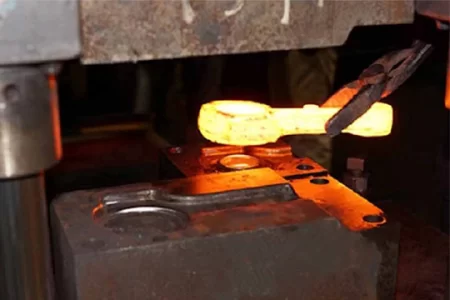

Overview of the hot forging process

Hot forging refers to heating the metal to a certain temperature and plastically deforming it through a forging press to produce parts with the required shape and performance. Hot forging has significant advantages compared to other processing methods, especially in improving the mechanical properties and structural integrity of the material. The grains of metal materials treated by hot forging are more refined, and the mechanical properties (such as tensile strength, yield strength, ductility, etc.) are significantly better than castings and cold-worked parts.

In mining machinery manufacturing, the hot forging process is widely used to produce various key parts with heavy load, impact resistance and wear resistance. Common forged parts include gears, shafts, connecting rods, crankshafts, couplings, etc. They play a vital role in the work of mining machinery.

Mining machinery working environment and parts requirements

Mining machinery usually operates under high pressure, high temperature, strong impact, and extremely corrosive environment. For example, equipment such as forklifts, excavators, and crushers often face huge loads, violent vibrations, and impacts when operating in mining areas. Therefore, its components need to have excellent mechanical properties, especially high strength, high wear resistance,e, and impact resistance.

High-strength requirements: The components of mining machinery need to withstand extreme workloads, especially under working conditions such as lifting, bulldozing, and crushing. Parts with insufficient strength are prone to cracking, breakage, or deformation, resulting in equipment shutdown and increased maintenance costs.

Wear resistance requirements: Mining equipment often rubs against hard ores, gravel and other particulate matter, so the surface of its parts needs to have high wear resistance. Parts with insufficient wear resistance will wear out quickly, shortening the life of the equipment.

Impact resistance requirements: The operating environment of mining machinery is full of instantaneous high-intensity impact forces. For example, when crushing ore, mechanical parts must withstand extremely strong impacts. Parts with poor impact resistance are prone to brittle fracture, causing equipment failure.

High-temperature resistance: During mining operations, equipment parts are often exposed to high-temperature environments, especially gears, bearings, and other components. They must have high-temperature resistance to ensure that they will not be affected by excessive temperatures during long-term work. High and cause failure.

Corrosion resistance: Mining machinery parts are often exposed to moisture, acidic or alkaline minerals, so their corrosion resistance is also particularly important. Components with poor corrosion resistance will be affected by the environment, leading to early failure.

Types of Mining Machinery Forged Parts

(There are more OEM mining equipment spare parts, but they are not convenient to show because we have signed a confidentiality agreement with customers.)

There are many types of parts that need to be forged in mining machinery, mainly including the following categories:

Gears and gear shafts: Gears and gear shafts are the most common and critical components in mining machinery. Mining machinery often needs to transmit power through a gear system, and gears and gear shafts are susceptible to extreme mechanical stress in high-load, high-impact working environments. Therefore, the hot forging treatment of gears and gear shafts must meet the requirements of high strength, impact resistance, and high wear resistance.

Crankshaft and connecting rod: The crankshaft and connecting rod are mainly responsible for the transmission of power and the conversion of mechanical motion in mining machinery. In high-load, high-speed operation environments, these components must have excellent fatigue and impact resistance.

Bearings: Bearings of mining machinery play an important supporting role to ensure the normal operation of the equipment. Bearings need to have high hardness, good wear resistance and low friction coefficient, so the forging process is crucial to improving their performance.

Hydraulic cylinder: Hydraulic systems are widely used in mining machinery. The sealing and wear resistance of hydraulic cylinders are crucial to the operation of the equipment. The forging process of hydraulic cylinders requires high strength and good corrosion resistance.

Transmission components: including chains, connecting pins, couplings, etc. The role of these components in mining machinery is to transmit power to different working parts, and they are required to have high strength, high wear resistance and long service life.

The hot forging process improves the performance of mining machinery parts

Improve the mechanical properties of materials: Hot forging refines metal grains through plastic deformation at high temperatures, significantly improving the strength and toughness of parts. Temperature control and deformation processes during forging help eliminate casting defects and improve the internal quality of the metal.

Optimize the microstructure: During the forging process, the organizational structure of the material is improved, and the metal grains become finer and more uniform, which can significantly improve the tensile strength, yield strength and ductility. Especially in the parts of mining machinery, this improved microstructure can effectively resist the pressure and impact from the external environment.

Improved wear resistance and corrosion resistance: The hot forging process can also further improve the wear resistance and corrosion resistance of parts through appropriate material selection and surface treatment technology. For example, the use of special alloy materials or surface carburizing, nitriding, and other treatments can enhance the wear resistance of parts and extend their service life.

Improve high-temperature resistance: Some parts of mining machinery work in high-temperature environments. The hot forging process can improve the high-temperature performance of the material by optimizing the alloy composition, ensuring that the parts will not suffer performance degradation or failure at high temperatures.

Reduce stress concentration: Through hot forging, the stress distribution of parts can be effectively controlled to avoid stress concentration areas and reduce the risk of fracture or fatigue failure.

Key technical requirements for the hot forging process

Selection of forging materials: Forging parts of mining machinery requires the selection of suitable metal materials, usually high-strength alloy steel, stainless steel, and tool steel. The performance characteristics of different materials determine their application scenarios in mining machinery.

Control of forging temperature: Forging temperature has an important impact on the plasticity and final properties of metal materials. Forging temperatures that are too high or too low will affect the fluidity, structure and mechanical properties of the metal. Therefore, precise control of forging temperature is the key to improving the quality of Mining Equipment Spare Parts.

Selection of forging equipment: Mining Equipment Spare Parts usually have large size and weight, so large forging equipment is required, such as high-tonnage hydraulic forging hammers or presses. In addition, the forging process also requires fine design and optimization of molds and tools to ensure high-quality production of parts.

Surface treatment technology: After hot forging, Mining Equipment Spare Parts usually require surface hardening treatments, such as carburizing, nitriding, plating, etc., to improve their wear resistance and corrosion resistance.

Heat treatment technology: Forged parts need to go through a series of heat treatment processes, such as normalizing, tempering, quenching, etc., to further optimize their mechanical properties and ensure that they can operate stably under extreme conditions.

Future development trends

With the continuous development and technological advancement of the mining industry, the demand for mining machinery parts continues to increase. In the future, mining machinery forging technology will develop in a more efficient, environmentally friendly, and intelligent direction. Intelligent control, the application of advanced materials and green production processes will become important development trends in mining machinery forging. In addition, with the advancement of computer simulation technology, forging

Advantages of HULK Metal forging

As a leading company specializing in Mining Equipment Spare Parts forging, we provide high-quality forged products to the global mining industry through advanced production technology and exquisite craftsmanship. Our advantages are reflected in the following aspects:

Advanced production equipment

We have state-of-the-art production equipment, including high-tonnage hydraulic forging hammers, presses, CNC machine tools and precision molds. These equipment ensure that we can handle various complex shapes and high-demand mining machinery parts, meeting customers' multiple needs for large size, precision and high performance.

Precise process control

We precisely control temperature, pressure, and deformation rate during the forging process to ensure that each product can achieve optimal metal structure and mechanical properties. Through strict process flow and quality control system, we ensure that forged parts have excellent strength, wear resistance,e, and impact resistance.

Material selection and optimization

We cooperate with a number of well-known domestic steel mills to select high-quality steel and alloy materials to ensure the high strength, corrosion resistance and high temperature resistance of mining machinery parts. For different application needs, we will also optimize the material ratio and composition according to the special requirements of customers to ensure that each product can perform well in extreme environments.

Professional design and R&D team

Our design and R&D team consists of experienced engineers and technical experts, capable of providing customized forging solutions according to customer needs. We not only provide traditional mining machinery parts but also develop intelligent, high-efficiency products that meet future trends. Through close cooperation with customers, we continue to optimize designs and improve the overall performance of parts.

Rigorous quality inspection

Our production process follows a strict quality management system. From the procurement of raw materials, and the execution of the forging process, to the delivery of the final product, every link is subject to strict quality control. We have advanced testing equipment, including hardness testing, tensile testing, impact testing, etc., to ensure that every forged product meets international quality standards. All products are ISO 9001 certified and meet CE, TUV, SGS, and other relevant certification requirements.

Powerful post-processing capabilities

In order to further improve the performance of mining machinery parts, we also provide advanced heat treatment and surface treatment processes, such as carburizing, nitriding, plating, etc. These post-treatment technologies can significantly enhance the product's wear resistance, corrosion resistance, and high-temperature resistance, thereby extending the service life of the equipment and reducing maintenance costs.

Fast delivery and flexible supply chain

With advanced production facilities and efficient production management, we are able to ensure on-time delivery of customer orders. In addition, we have a complete logistics system that can provide customized distribution services based on customers' geographical location and transportation needs. We are committed to providing customers with flexible and reliable supply chain support to ensure timely delivery of parts and components and improve the production efficiency of mining machinery.

Industry experience and customer reputation

As an industry-leading forging manufacturer of mining machinery parts, we have accumulated rich industry experience and established long-term cooperative relationships with many well-known mining companies around the world. Our products are widely used in mining, metallurgy, construction, energy, and other fields, and are well-received by customers. Our technical strength and product quality have been widely recognized.

Innovation and sustainable development

We always adhere to technological innovation, actively introduce advanced forging technology and equipment, and continuously improve production efficiency and product performance. At the same time, we also focus on environmental protection and sustainable development, striving to minimize the impact on the environment while meeting customer needs. Through continuous technology research and development and process improvement, we are committed to providing customers with more efficient and environmentally friendly forging products.

We are committed to providing high-performance, high-quality forged parts for the mining machinery industry. With advanced production technology, exquisite workmanship, strict quality control, and flexible customer service, we always provide customers with reliable solutions to help them improve the performance and service life of their mining machinery. Our products are widely used in major mines around the world and have won high trust and support from customers with their excellent quality.

As a leader in the industry, we will continue to uphold the core values of innovation, quality, and service, continue to promote the progress of the forging process of mining machinery parts, and make more contributions to the sustainable development of the mining industry.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE