By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

An Ultimate Guide of Precision CNC Machining

In today’s competitive manufacturing landscape, precision isn’t just a buzzword—it’s the foundation of product reliability, performance, and cost-effectiveness. CNC (computer numerical control) machining has revolutionized how parts are made, enabling intricate geometries, tight tolerances (often within ±0.01 mm), and consistent repeatability at high volumes. Whether you’re in aerospace, medical devices, automotive, or electronics, precision CNC machining delivers the exacting standards your application demands.

What Is Precision CNC Machining?

Precision CNC machining refers to computer-driven subtractive processes that remove material from a solid billet to create parts meeting exact dimensional and surface requirements. Unlike manual machining, CNC relies on CAD (computer-aided design) and CAM (computer-aided manufacturing) software to generate G-code programs, automating tool paths, spindle speeds, and coolant control for maximum accuracy.

Types of CNC Machining Processes

Milling

CNC milling employs computer-controlled rotating cutters to systematically remove material from a workpiece, offering both speed and precision for complex geometries. Modern 3-axis mills move tools along X, Y, and Z axes, while advanced 5-axis centers introduce two additional rotary axes, enabling the cutter to approach parts from virtually any orientation without manual re-clamping. This multi-axis flexibility allows undercuts, intricate contours, and multi-surface machining in a single setup, drastically reducing cycle times and improving overall accuracy. High-precision micro-milling can even achieve tolerances down to 2–3 µm for minute features in medical and electronics applications.

Turning

In CNC turning, the workpiece spins against a variety of stationary cutting tools to produce rotational parts such as shafts, bushings, and flanges. Standard lathes provide facing, grooving, and parting operations, while “live-tooling” lathes incorporate rotating tools in the turret, enabling milling, drilling, and tapping all in one fixture. This integration of milling functions within the turning center minimizes part handling, boosts concentricity, and cuts secondary setup times by up to 50%, making it ideal for high-precision, high-volume production.

Electrical Discharge Machining (EDM)

EDM removes conductive material via precisely controlled electrical sparks between a wire or electrode and the workpiece, vaporizing microscopic bits without physical contact. Wire EDM routinely achieves tolerances as tight as 1 µm after trim passes, making it perfect for hard alloys and complex internal cavities that conventional cutters cannot reach. Despite its slower material-removal rate compared to milling, EDM excels in machining refractory materials and producing components for aerospace and medical implants with exceptional surface quality.

Grinding

CNC grinding uses abrasive-wheel spindles to finish surfaces with ultra-fine precision and superb surface integrity. With tolerances frequently held to Min IT5 (1 µm), grinding is essential for components requiring mirror finishes or extremely tight dimensional control, such as precision tooling, bearing races, and hardened shafts. Both cylindrical and surface grinders automate dressing cycles and wheel compensation via closed-loop controls, ensuring consistent finishes (Ra < 0.1 µm) and repeatability across long production runs.

Laser & Waterjet Cutting

Non-contact laser cutting employs high-powered beams to vaporize or melt through sheet and plate materials, yielding kerfs as narrow as 0.08–0.6 mm, depending on material and laser type. This precision, combined with minimal heat-affected zones, makes laser ideal for stainless steel, aluminum, and exotic alloys. Waterjet cutting, using high-pressure abrasive-laden water streams, achieves accuracies to Min IT5 without thermal distortion, handling any material from composites to hardened steels while producing burr-free edges.

Punch Press

CNC punch presses rapidly perforate or contour sheet metal by descending programmed punches through dies, perfect for high-volume production of enclosures, brackets, and panels. Modern presses feature turret systems with upwards of 20 tools, enabling holes, louvres, and formed features in a single pass to tight positional tolerances of ±1 µm. Integration with automated material loaders and real-time tool monitoring further elevates efficiency and part consistency in industries such as electrical enclosures and automotive stamping.

The Precision Machining Workflow

1. Roughing: High-feed, large-diameter tools remove bulk material quickly, leaving a small allowance for finishing.

2. Semi-finishing: Intermediate passes refine geometry, reducing scallops and preparing surfaces for final cuts.

3. Finishing: Light passes with fine-tip tools (sometimes under High Speed Machining regimes) achieve final tolerances and smooth surface finishes (Ra < 0.4 µm).

4. Post-processing: Deburring, shot-peening, heat treatments, and coatings (anodizing, plating) add functional and aesthetic value.

Quality Control for CNC Parts

Effective quality control (QC) in CNC machining integrates precise measurement tools, rigorous testing protocols, comprehensive documentation, and data-driven monitoring to ensure every part meets design specifications and regulatory standards. By combining Coordinate Measuring Machines (CMMs) and manual gauges with surface and hardness testing, traceability systems, and Statistical Process Control (SPC), manufacturers can detect and prevent defects early, maintain continuous improvement, and deliver consistent, high-quality components.

Dimensional Inspection

Dimensional inspection verifies part geometry using both automated and manual methods. Coordinate Measuring Machines (CMMs) employ touch probes or laser scanners to measure features in three dimensions with micron-level accuracy, detecting deviations as small as ±0.001 mm. Calibrated micrometers and vernier calipers supplement CMMs for spot checks on critical features, offering quick verification during production runs. Regular calibration of all measuring instruments against national standards is mandatory to ensure measurement integrity over time.

Surface & Hardness Testing

Surface roughness directly affects part performance, wear resistance, and assembly fit. Profilometers drag a stylus across the workpiece surface, generating Ra, Rz, and other parameters to quantify texture against spec limits. For material properties, Rockwell and Vickers hardness testers apply controlled indentations to evaluate strength and heat-treatment efficacy, critical for components subjected to high stress or abrasion.

Traceability & Documentation

Traceability links each part to its production batch, raw material source, and inspection records. Implementing ISO 9001 protocols requires maintaining material certificates, equipment calibration logs, and operator shift reports, ensuring full accountability from billet to finished component. Digital batch records and barcoded part IDs enhance data accuracy and retrieval, supporting audits and customer inquiries.

Statistical Process Control (SPC)

SPC employs control charts and real-time data analytics to monitor key dimensions and process variables. Software platforms collect measurements from CMMs, in-line probes, and manual gauges, calculating Cp, Cpk, and other capability indices to flag trends before they lead to nonconforming parts. Automated alerts enable engineers to adjust cutting parameters or tool paths proactively, reducing scrap rates and stabilizing production quality over long runs.

Why Choose HULK Metal for Precision CNC Machining

State-of-the-Art Equipment

3-, 4-, and 5-axis CNC centers capable of sub-micron repeatability.

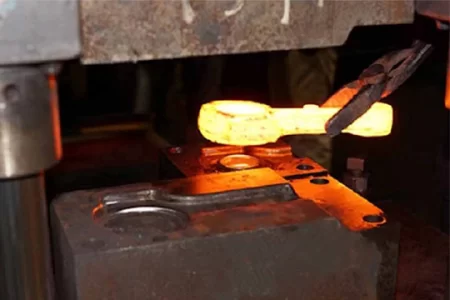

Integrated Hot Forging & Machining

In-house forging ensures superior grain structure and mechanical properties before final CNC finishing.

Rigorous QC & Certifications

ISO 9001:2015, CE, and TÜV certified; each part undergoes multi-stage inspection.

Customization & Scalability

From single prototypes to large production runs, turnkey solutions tailored to your blueprints.

Responsive After-Sales Support: Dedicated technical team, rapid replacement or rework if parts ever fall short.

Precision CNC machining is the backbone of high-performance manufacturing—delivering the tight tolerances, surface finishes, and consistency your products demand. By partnering with HULK Metal, you gain access to cutting-edge equipment, deep forging expertise, and uncompromising quality control. Contact us today for a free DFM review and quote, and experience why leading OEMs trust HULK Metal for their most demanding applications.

Article Navigation

Article Navigation

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE