HULK Metal provides high-quality metal forgings to many industries including construction hardware, trailer manufacturing, automotive exterior decoration, powerline hardware, fitness equipment, and many more.We provide high-quality products, services and solutions to global leading companies.

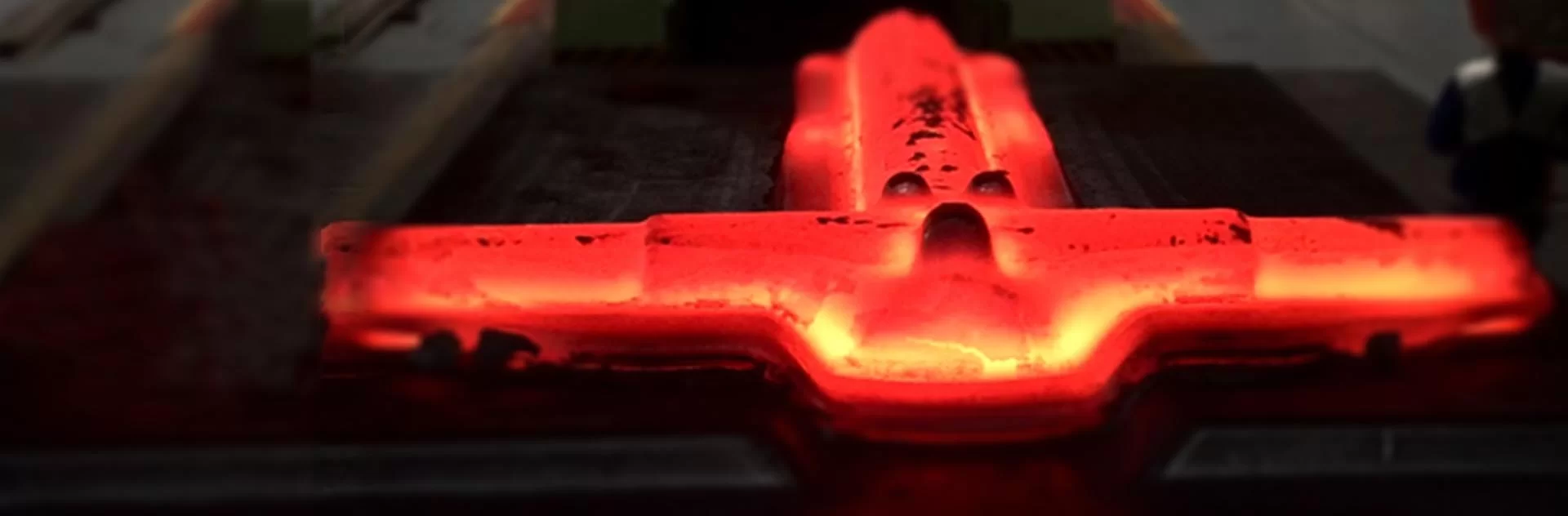

Provide Precision Hot Die Metal Forgings

REQUEST A QUOTE

HULK METAL STRENGTHEN

HULK Metal specializes in the production and sales of high-quality metal forgings and has established a complete product quality management system. We provide you with professional management and integrated services from beginning to end to better complete each of your metal forging orders.

When you choose HULK Metal as your preferred metal forging service provider, you'll enjoy fast delivery and competitive pricing. Let our team of engineers design a custom solution based on your specific needs!

Get Better Forging Solutions

HULK Metal specializes in the production and sales of high-quality metal forgings and has established a complete product quality management system. We provide you with professional management and integrated services from beginning to end to better complete each of your metal forging orders.

When you choose HULK Metal as your preferred metal forging service provider, you'll enjoy fast delivery and competitive pricing. Let our team of engineers design a custom solution based on your specific needs!

TYPE OF METAL FORGING SERVICES

We mainly provide hot die forging services. The forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium, etc. and their alloys. You can click on the link below to learn more.

-

HOT FORGING

SERVICEAs a major metal forming process, forging uses local compression force to shape metal. During hot forging, since the deformation energy and deformation resistance are very small, large forgings with complex shapes can be forged. If you want to obtain forgings with high dimensional accuracy, you can use hot forging in the temperature range of 900-1000°C. We will develop a processing plan based on the size, accuracy, and materials of your customized forgings and provide zero-defect forgings.

READ MORE

-

DIE FORGING

SERVICEWe select die forgings based on the complexity, precision and material of the metal forging. If the workpiece is relatively large or long, then open-die forging is required. The mold investment cost of open-die forging is relatively low, so it is suitable for small batch orders. Compared with open-die forging, closed-die forging can process workpieces with more complex structures and sizes close to finished parts. Open-die forging can reduce the cutting allowance required for machining of forgings, save the weight of consumed materials and thereby reduce production costs. If you need metal forging services, you can contact us!

READ MORE

-

CARBON STEEL FORGING

SERVICECarbon steel is a material we often use when forging. Carbon steel has high strength and strong plasticity. It can be plastically deformed through forging to produce forgings with complex shapes. It is used in different industries. If you need large quantities of forgings, please contact us and we are committed to simplifying the pricing calculation process to provide you with more convenience.

READ MORE

-

STAINLESS STEEL FORGING

SERVICEOur forging process enhances the material's structural integrity, resulting in stainless steel forgings with superior mechanical properties. Stainless steel forgings are used in a wide range of applications, providing optimal solutions for critical components, meeting strict quality standards and helping to extend product life. We hope that our professional hot die forging services can help you get the forgings you want faster.

READ MORE

-

ALLOY STEEL FORGING

SERVICEThe forging of different special alloy steels has both commonalities and individual characteristics. Alloy steel has special properties such as high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, and non-magnetic properties. If you need alloy steel metal forgings, please send us the drawings and we will provide you with an advantageous price.

READ MORE

-

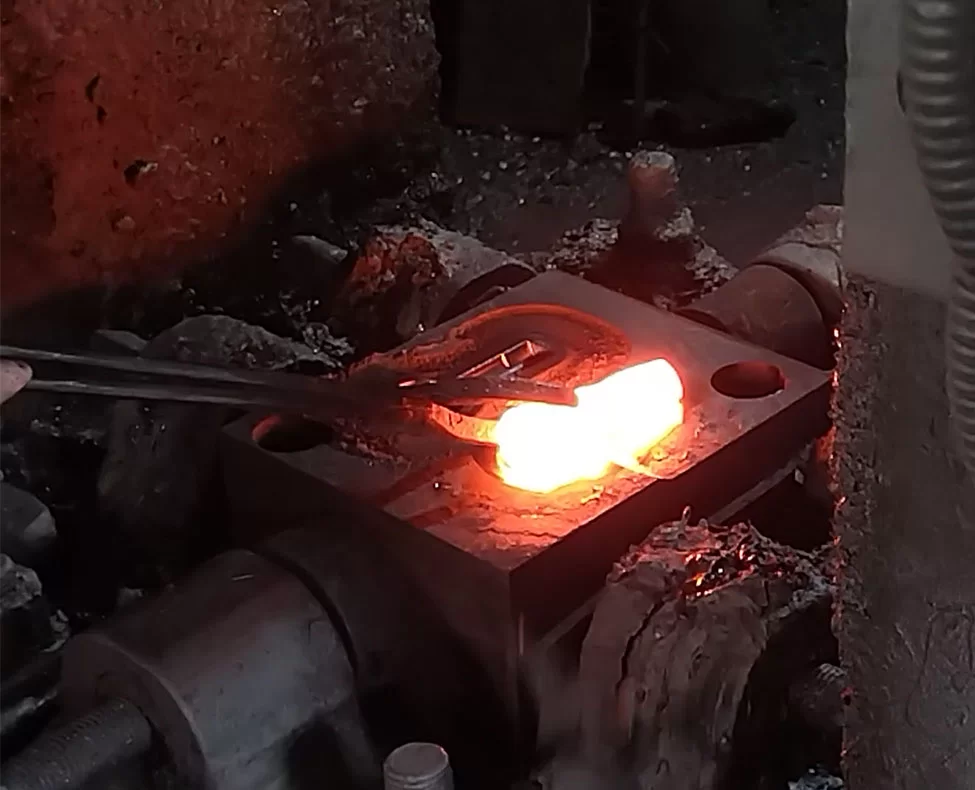

MOLD MAKING

SERVICEForging molds are used in metal forging services. In the case of open-die forging, the production of upper and lower molds is essential, while closed-die forging requires the use of two or more metal molds. As a producer of professional metal forging services, our comprehensive supply chain covers mold making services. Through our supply chain, customers can purchase molds of the same quality at more economical prices. So trust us with your metal forging needs with confidence!

READ MORE

-

MACHINING

SERVICEWhile forging production is carried out, a series of processes such as stamping, welding, machine tool turning precision machining, and centering machining are also carried out simultaneously. Our machining services put precision and efficiency first, and rely on advanced technology and professional processes to provide you with The demand for forging has been raised to a new level. Contact us now and take advantage of reduced delivery times and cost-effectiveness.

READ MORE

Please contact us and our team of engineers will provide you with a tailor-made solution and quote to meet your requirements quickly and cost-effectively.

HULK METAL SUPPLIES

BETTER FORGING SERVICE

Since 2000, HULK Metal (Qingdao Hulk Metal Technology Co., Ltd) is a company specializing in metal processing services. The business content includes metal forging, metal casting, metal fabrication, etc. It can supply various precision forgings, cast steel and iron parts with various casting processes, and profile machined parts, including cutting sheet metal, welding, surface treatment, assembly, etc. Solutions and one-stop service.The company has established a complete product quality management system and has passed ISO9001 and other certifications...

REQUEST A QUOTE

Forging Factory Show

INDUSTRIES WE SERVED

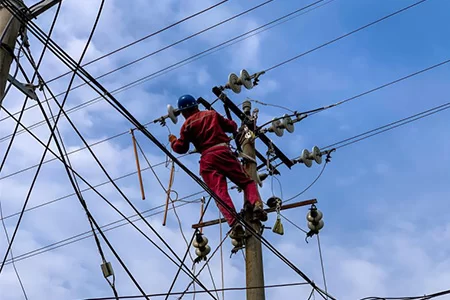

The forging services we provide cover construction hardware, trailer manufacturing, automotive exterior decoration, powerline hardware, fitness equipment, mining machinery, food machinery and many other industries. We support processing according to drawings and samples, and will develop a complete solution through continuous negotiation according to your requirements. The content of the plan includes production technology, shipping and packaging, delivery time, freight, after-sales service and price, etc.

-

Cable & Wire Grips

Cable & Wire GripsAs a professional cable & wire grips manufacturer, HULK Metal has carried out in-depth cooperation with world-renowned lifting machinery companies, and are committed to providing high-quality, reliable cable & wire grips. Based on advanced technology and strict quality control, we continue to innovate in research and development to ensure that our products meet industry standards and customer needs. In the process of cooperation, we are not only suppliers, but also partners, fully understanding customer needs and providing professional solutions. Our cable & wire grips are widely used in construction, highways, bridges, metallurgy, mining, slope tunnels, shaft management and protection and other industries to provide customers with stable and efficient working performance. We will continue to cooperate with world-renowned lifting machinery companies to jointly promote the development of the industry and create greater value for customers.

READ MORE

-

Trailer Accessories

Trailer AccessoriesOur hot forging facility specializes in manufacturing high quality trailer accessory forgings, providing our customers with a range of precision engineered and manufactured components. Our product line covers a variety of key components, including but not limited to shackles, tow balls, tow hooks, etc.

READ MORE

-

Construction Hardware

Construction HardwareWe provide professional construction hardware forging processing services, and are proficient in the processing technology of carbon steel, alloy steel, and stainless steel. Our forging process uses advanced technology and equipment to ensure product precision and durability. We have professional machining equipment that can meet the processing needs of various complex parts and ensure perfect fit and accuracy of products. In addition, we offer a variety of surface treatment options, including galvanizing, spray painting, and anti-corrosion treatments, to enhance product durability and aesthetics. Our heat treatment services ensure products achieve the required hardness and strength to suit the needs of various construction environments. Our team has extensive experience and expertise and is committed to providing the best solutions to our clients and ensuring projects are delivered on time and to the highest standards of quality.

READ MORE

-

Mining Equipment Spare Parts

Mining Equipment Spare PartsHULK Metal is a professional manufacturer focusing on the production of mining equipment spare parts, committed to providing customers with efficient and reliable solutions. We have established long-term and solid cooperative relationships with many mining equipment manufacturers and spare parts dealers, and can fully grasp the latest industry technologies and market demands. Our spare parts are strictly produced in accordance with international standards, covering multiple application areas such as mining, construction, oil fields, ships and ports, forestry, agriculture, etc., providing high-quality parts for any heavy machinery. Our rich experience means that we can provide the highest quality mining equipment and spare parts at the lowest price in the shortest time. By choosing HULK Metal, you will get a comprehensive guarantee of fast delivery, high-cost performance, and perfect after-sales support.

READ MORE

-

Forging Parts

Forging PartsAs a professional hot forging factory, HULK Metal has accumulated rich experience in many industries. We are committed to providing customers with high-quality forging solutions.

READ MORE

-

Metal Exterior Accessories For Car, SUV, Truck

Metal Exterior Accessories For Car, SUV, TruckHULK Metal can provide a series of metal exterior accessories, covering various precision components, including toggle clamps, bolts, etc., suitable for various types of cars, SUVs, and trucks. Each of our products is produced using advanced forging technology to ensure high strength, excellent elasticity, and long-term durability. These characteristics are critical for car, SUV, and truck applications. Please provide product drawings and samples, and our engineering team will provide a professional quotation based on your needs.

READ MORE

More Results

You only need to provide drawings, and we will formulate solutions, calculate prices, and complete orders until delivery.

METAL FORGING NEWS

Here is a collection of various articles about metal forging, such as introductions to the forging process and materials. You can find what you need.

- News

- Technology

-

December 11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

September 14, 2024

Types of Jaw Wire Grip and Suitable Use Scenarios

READ MORE

-

September 13, 2024

Cable grip VS Wire Grip Comprehensive Detailed Analysis

READ MORE

-

September 12, 2024

Do you know the comprehensive analysis of wire grip puller?

READ MORE

-

September 06, 2024

Why can wire rope grip clamp cables?

READ MORE

-

September 02, 2024

Things to note when purchasing a jaw wire grip

READ MORE

-

August 27, 2024

Does the operation of wire grips conflict with oil lubrication?

READ MORE

-

August 26, 2024

How to use Jaw Wire Grips?

READ MORE

-

July 26, 2024

What kind of inspections should be done before choosing a wire gripper?

READ MORE

-

July 15, 2024

Wire Cable Grips: Types, Mechanisms, and Applications

READ MORE

-

July 01, 2024

Difference between hot forging and cold forging

READ MORE

-

June 27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January 18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

October 24, 2024

Technical Standards Analysis of Wire Cable Grip: Why It is So Important

READ MORE

-

October 18, 2024

Wire Grip: High-Performance Solutions with Advanced Materials and Precision Engineering

READ MORE

-

October 17, 2024

Wire grip performance test method

READ MORE

-

October 11, 2024

Application of Jaw Wire Grip in Overhead Wire Rope

READ MORE

-

September 30, 2024

Jaw wire grip made of high-strength alloy steel: a comprehensive analysis from material selection to production process

READ MORE

-

July 25, 2024

How to Choose the Perfect Cable Grips for Your Needs?

READ MORE

-

July 03, 2024

What are the processes of hot forging?

READ MORE

FREQUENTLY ASKED QUESTIONS

Here is a collection of questions about metal forging that HULK Metal customers have asked so far. You can find what you want here.

-

We will conduct the tests listed below and attach a test report for each order.

-

You may want to know the production progress of your order or want to know how your order is produced.

On the one hand, we will send you the order production progress through pictures and videos.

-

QINGDAO HULK METAL Technology Co. Ltd (hereinafter referred to as "we") takes your privacy and personal information very seriously and is always committed to protecting your privacy.

-

Please check the quality of the goods when you receive them. If the product is defective, or damaged, or received the wrong goods, contact us immediately, and we can solve it through timely negotiation.

-

You can send samples to us. After receiving your sample, our professional engineers will evaluate it in detail and provide an accurate quotation.

-

We can provide electro-galvanizing, hot-dip galvanizing, powder coating, electrophoresis, phosphating, bluing, polishing, wire drawing, and other surface treatments.

-

Sure. However, our scope of capabilities mainly covers the use of 2D drawings for 3D drawings, and drawings based on samples. We focus on providing OEM services to our customers, so we cannot meet your ODM needs.

-

Here's the key information we need to know to better serve your needs:

1. Please provide detailed drawings, which can be in 2D or 3D format. If drawings are not available, please provide samples.

2. Please clearly specify the material of the required product, if it is not mentioned in the drawing.

3. Please tell us the quantity of products you need.

4. Please provide your desired delivery terms.

-

Our quality control center is equipped with a series of advanced testing equipment, including micrometers, vernier calipers, tensile testing machines, impact testing machines, Rockwell hardness testers, Brinell hardness testers, electron microscopes, photometers, salt spray testing machines, CMM, etc.

-

T/T, L/C, etc. Kindly contact our sales manager to determine the specific payment method.

-

We mainly provide hot die forging services. The forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium, etc. and their alloys.

-

At our forge, we understand the uniqueness of each project and our customers' stringent lead-time requirements.