By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Most Common Heat Treatments for Alloy Steel Hot Forging Parts

In the world of industrial manufacturing, alloy steel hot forging parts play a critical role in creating components that are built to last. From automotive parts to heavy machinery, forged alloy steel components are trusted for their strength, durability, and precision. But to unlock their full potential, one essential step cannot be skipped—heat treatment.

Heat treatment is more than just a technical requirement; it’s what transforms a forged part into a high-performance product ready to handle real-world demands. Whether you need superior hardness for wear resistance or softer materials for easier machining, heat treatment is the process that makes it possible.

In this article, we’ll break down the most common heat treatment methods used for alloy steel hot forging parts, why they matter, and how HULK Metal ensures every forged piece meets the highest standards.

Why Heat Treatment is Essential for Alloy Steel Forgings

When a forged part comes out of production, it doesn’t yet have the full mechanical strength or flexibility required for its intended use. That’s where heat treatment comes in.

The Key Benefits of Heat Treating Forged Alloy Steel Components:

Improved Strength and Hardness: Making parts strong enough to handle wear and tear.

Enhanced Wear Resistance and Durability: Critical for parts like gears, shafts, and industrial tools.

Reduced Internal Stress from Forging: Preventing cracks and failures during use.

Optimized Machinability: Making it easier to perform secondary operations like drilling, threading, or cutting.

Without proper heat treatment, even the strongest alloy steel hot forging parts may fall short in real-life performance. That’s why manufacturers like HULK Metal apply customized heat treatment for every project, ensuring both reliability and longevity.

The Hardening Process of Heat Treating Alloy Steel Forgings

What is Hardening?

Hardening is the go-to heat treatment method when the goal is to make forged alloy steel parts extremely tough and wear-resistant. You’ll often see this process used for shafts, gears, bearings, and other parts exposed to friction, pressure, or rotational force.

The primary goal of hardening is to create a surface that can resist wear without changing the part’s shape. However, the process needs to be done correctly. If not, the part may become brittle and prone to breaking.

Step-by-Step Hardening Process

Heating to Critical Temperature: The forged alloy steel part is heated until it glows red-hot. This usually happens at temperatures around 800–900°C, depending on the specific alloy grade.

Rapid Quenching in Water or Oil: Once the part reaches the desired temperature, it’s cooled rapidly by immersion in water or oil. This sudden drop in temperature locks the steel’s structure into a hardened state.

Tempering Process (Achieving Blue Color): Because the hardened steel is now very brittle, it undergoes a second heating phase, called tempering. This is done until the steel surface reaches a “blue” appearance, indicating the correct internal toughness.

Controlled Cooling: Finally, the tempered steel cools down to room temperature. After this, the forged alloy steel part has achieved a balance of strength and toughness.

Hardening is essential for precision forging, where wear resistance is critical. Once hardened and tempered, the forged part is ready to take on extreme workloads without deforming or cracking.

The Role of Tempering in Forged Alloy Steel Parts

Tempering goes hand-in-hand with hardening. Why? Because hardening alone makes the steel brittle. You don’t want a shaft or gear snapping under pressure because it’s too hard to handle flexibility. That’s where tempering comes in—to find that sweet spot between strength and flexibility.

Benefits of Tempering Forged Alloy Steel:

Increased Toughness: Prevents brittle failures.

Enhanced Durability: Especially for high-load applications.

Reduced Internal Stress: Improves stability under fluctuating forces.

For industries that rely on tempered alloy steel, especially high-strength forging applications, tempering is a non-negotiable step in production.

Softening Treatments: Annealing and Normalizing

Not every forged alloy steel part needs to be hard. Sometimes, you want parts that are easier to machine or shape during later production steps. That’s where softening heat treatments like annealing and normalizing come into play.

Annealing Process

Annealing is designed to soften the alloy steel, making it easier to cut, form, or bend during post-forging operations. This is especially important for components that require complex machining after forging.

Key Benefits of Annealing:

Reduces internal stress.

Improves ductility, making the material less likely to crack.

Enhances machinability for secondary operations.

Restores toughness lost during forging or earlier treatments.

During annealing, the forged alloy steel part is heated to a specific temperature and then cooled very slowly, usually in a furnace. This slow cooling process allows the internal grain structure to reform into a softer, more uniform pattern.

For parts where flexibility and machinability matter, annealed forging parts are the ideal choice.

Normalizing Process

Normalizing is similar to annealing but is specifically used to refine the grain structure of the forged steel. After processes like rolling, casting, or hot forging, the steel’s internal structure may become uneven, leading to weak spots. Normalizing fixes that.

How It Works:

The forged alloy steel is heated between 830–950°C.

It’s then cooled by exposure to air.

The result? A consistent, uniform internal grain structure that performs better under stress.

By refining the steel’s grain, normalizing creates normalized alloy steel that offers consistent strength, toughness, and machinability. This is especially valuable for stress relief forging processes following intense manufacturing steps.

Comparison of Heat Treatment Methods for Alloy Steel Forgings

Heat Treatment Type | Purpose | Process Summary | Best Applications |

Hardening | Increase surface strength | Heating → Quenching → Temper | Shafts, gears, load-bearing parts |

Tempering | Improve toughness | Re-heating → Controlled Cool | High-stress forging applications |

Annealing | Soften & improve ductility | Heating → Slow Cool | Machinable forging parts |

Normalizing | Relieve stress/refine grain | Heating → Air Cooling | After forging, casting, rolling |

Choosing the right treatment depends on the intended use of the forged part. Some components require a combination of these treatments to meet exact mechanical specifications.

How HULK Metal Ensures Superior Heat Treatment for Alloy Steel Forgings

At HULK Metal, we know that precision forged steel with heat treatment is more than just a product—it’s a promise of quality. That’s why we go the extra mile to make sure every forged alloy steel component we deliver meets or exceeds your expectations.

What Sets HULK Metal Apart:

Advanced Heat Treatment Facilities: Our workshops are equipped with cutting-edge furnaces, quenching tanks, and tempering equipment.

Experienced Technical Teams: Our metallurgists and forging experts design custom heat treatment plans for every order.

Customized Processes: We adjust temperatures, cooling rates, and time schedules based on material grades and application requirements.

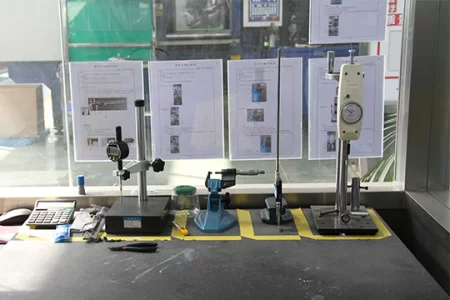

Strict Quality Control: Each part undergoes dimensional inspection, hardness testing, and surface quality checks.

With high-quality alloy steel forging, we don’t just deliver parts—we deliver solutions. Whether you need tempered forging parts for extreme loads or annealed forging parts for precision machining, our expertise ensures you get exactly what you need.

Choosing the Right Heat Treatment for Your Forged Parts

Not sure which heat treatment is right for your project? That’s what we’re here for. The ideal process depends on:

The mechanical properties required by the application.

How much stress will the part endure during use?

Whether or not secondary machining will be performed.

With custom alloy steel forging parts, one size never fits all. We provide expert guidance to help you select the right combination of heat treatment for forged parts to guarantee success.

From forged alloy components for industrial applications to durable forging parts heat-treated for strength, HULK Metal is the partner you can trust for every forging need.

Heat treatment is the silent hero behind every successful alloy steel forging project. It turns raw strength into refined performance, shaping parts that stand up to real-world demands. With processes like hardening, tempering, annealing, and normalizing, alloy steel hot forging parts are tailored to perform exactly as they should, whether in extreme temperatures, heavy loads, or high-speed environments.

At HULK Metal, we don’t just produce forged parts—we engineer success stories. Ready to boost your next project with high-quality hot forging and professional heat treatment? Get a quote for hot forging parts today and discover the HULK Metal difference.

Article Navigation

Article Navigation

Industries

Foundries

-

December.11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

February.28, 2025

Open Die Forging: Exploring the forging process and the key factors in selecting a OEM

READ MORE

-

February.24, 2025

Key Considerations for Closed Die Forging

READ MORE

-

February.18, 2025

Factors to consider when purchasing custom forgings

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE