By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

How to Find an OEM Metal Forging Factory?

In today’s competitive manufacturing landscape, selecting the right OEM (Original Equipment Manufacturer) metal forging partner is critical for ensuring product performance, cost efficiency, and on-time delivery. Whether you require high-volume hot-forged components or complex, precision-machined parts, a strategic forging partner can make the difference between success and setback. This guide provides a comprehensive, step-by-step approach to identifying and evaluating OEM metal forging factories, empowering you to make informed decisions that optimize quality, lead times, and total cost of ownership.

Understanding OEM Metal Forging

What “OEM Forging” Really Means

OEM forging refers to the process by which a forging factory produces custom-designed metal components directly for an equipment manufacturer. Unlike distributors or brokers, an OEM forging partner handles everything from die design and material procurement through final finishing, ensuring full traceability, consistent quality, and adherence to your specifications.

Hot Forging vs. Cold Forging: Key Differences

Hot Forging: Involves heating metal above its recrystallization temperature to improve ductility and shape complex profiles with lower press loads. Ideal for large, structurally demanding parts such as shafts, crankshafts, and heavy hooks.

Cold Forging: Conducted at or near room temperature, yielding superior surface finish and tight dimensional tolerances. Best for high-precision, small- to medium-sized components like fasteners and fittings.

Defining Your Requirements

Material Types and Grades

Identify the precise alloy grade and material properties you need. Common choices include:

Carbon Steel: Cost-effective, good strength, widely used in general-purpose applications.

Alloy Steel: Enhanced mechanical properties for high-stress environments (e.g., chromium-molybdenum steels).

Stainless Steel: Corrosion resistance for harsh or hygienic applications.

Part Complexity, Size, and Tolerances

Define part geometry, weight, and dimensional tolerances upfront. Complex shapes with deep ribs or thin walls may require specialized forging presses and advanced die design. Tolerance requirements (e.g., ±0.1 mm vs. ±1 mm) directly affect process choice, scrap rates, and inspection methods.

Annual Volume and Scalability

Estimate your current and projected annual volume. High-volume runs (tens of thousands per year) justify investment in dedicated tooling and automated finishing, while low-volume or prototype orders may be better served by adjustable dies or charge-per-piece models.

Evaluating Factory Capabilities

Production Technologies

Open-Die Forging: Flexible shaping for large, simple parts; lower tooling costs but higher labor input.

Closed-Die (Impression-Die) Forging: Precise contours and repeatability; excellent for medium to high volumes.

Rotary Forging (Orbital/Swaging): Efficient for rings, flanges, and disks; minimal material waste.

Equipment and Capacity

Assess press capacity (tonnage), die life, and finishing equipment:

Press Tonnage: Ensure presses can handle your part’s forging force requirements.

CNC Machining: In-house finishing capability reduces lead times and logistics.

Heat Treatment: On-site furnaces enable rapid turnaround for normalized, quenched, or tempered parts.

In-House vs. Outsourced Processes

A vertically integrated factory offers tighter control and shorter lead times. Outsourcing key steps like machining, shot blasting, or plating can introduce scheduling variability and quality risks. Prioritize partners that maintain critical processes under one roof.

Quality Assurance & Certifications

Industry Standards

Look for certifications such as ISO 9001 (quality management), IATF 16949 (automotive), or AS 9100 (aerospace). These demonstrate structured processes and continual improvement.

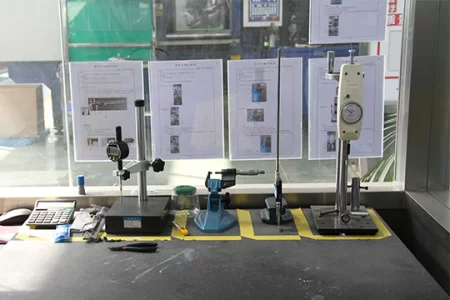

On-Site Testing Capabilities

Best-in-class OEM forgers perform:

Ultrasonic and Magnetic Particle Inspection for internal defects.

Metallographic Analysis to verify grain structure and recrystallization.

Mechanical Testing (tensile, Charpy impact) to confirm strength and toughness.

Traceability and Documentation

Ensure each batch of forgings comes with full material certificates (e.g., EN 10204 3.1), heat numbers, and inspection reports. This level of documentation is essential for regulated industries and critical applications.

Supply Chain & Logistics

Raw-Material Sourcing and Storage

A reliable OEM forging factory secures multiple certified steel mills as raw-material suppliers to mitigate disruptions. Proper warehouse conditions (humidity control, first-in/first-out) preserve material integrity.

Lead Times and Inventory Management

Confirm typical lead times—from tooling design to first-article inspection (FAI) and mass production. Partners offering Vendor-Managed Inventory (VMI) or Kanban replenishment can dramatically shorten your supply chain.

Packaging, Export Compliance, and Freight

Specialized export packaging (e.g., anti-rust coatings, sea-worthy crates) protects forged parts in transit. Evaluate the factory’s experience with your destination country’s import regulations, customs clearance, and freight options (air vs. sea vs. rail).

Assessing Cost vs. Value

Transparent Quoting Practices

Look for detailed quotations that break out tooling costs (die design, die manufacturing), per-piece forging costs, finishing, and overhead. Beware of “all-in-one” quotes lacking clarity on fixed vs. variable expenses.

Total Cost of Ownership

Consider scrap rates, rework, inspection costs, and warranty service expenses. A lower per-piece price may hide high scrap percentages or post-shipment replacement charges.

Negotiation Tips and Volume Discounts

Tooling Amortization: Spread die costs across your projected volume to negotiate better per-piece pricing.

Long-Term Contracts: Commit to multi-year purchase agreements in exchange for reduced rates.

Loyalty Programs: Some OEM forgers reward repeat business with tiered discounts or expedited scheduling.

Factory Audits & Visits

What to Look For

During a site audit, observe shop organization, 5S implementation, and maintenance schedules. A clean, orderly shop floor is often correlated with rigorous quality control.

Key Questions to Ask

How many die sets are in use, and what is their average life?

What is your on-time delivery rate?

Can you provide recent performance metrics (scrap rate, customer returns)?

Red Flags and Warning Signs

Lack of documented procedures or traceability.

Frequent machine breakdowns causing missed deadlines.

Reluctance to share audit results or third-party inspection reports.

Sample Runs & Prototyping

First-Article Inspection (FAI) Process

A thorough FAI includes dimensional measurement, material verification, and functional testing. Ensure your partner provides a formal FAI report before authorizing mass production.

Iterating Dies and Design Adjustments

Collaborate on die modifications to address flash removal, die wear, or part fill issues. Agile forgers can iterate quickly to refine tolerances and surface finish.

Validating Real-World Performance

Subject prototypes to real operating conditions—load testing, fatigue cycling, or corrosion exposure—to verify that forged parts meet end-use requirements.

After-Sales Support & Long-Term Partnership

Warranty and Replacement Policies

Clarify warranty terms for material defects or dimensional non-conformance. Fast replacement or rework turnaround is vital for maintaining your production schedules.

Continuous Improvement Programs

Top OEM forgers conduct periodic business reviews and process audits, proposing lean initiatives, Six Sigma projects, or joint value-engineering workshops.

Building a Strategic Supplier Relationship

Treat your supplier as a partner. Share forecasts, design roadmaps, and market insights to foster collaboration, reduce risks, and unlock innovation opportunities.

Choosing an OEM metal forging factory is a strategic decision that impacts product quality, cost efficiency, and time-to-market. Use the checklist below as a final reference:

Define material and tolerance requirements

Verify production technologies and in-house capabilities

Confirm certifications and testing procedures

Scrutinize lead times, logistics, and cost structures

Conduct site audits and review sample runs

Establish clear after-sales support and partnership programs

At HULK Metal, we combine state-of-the-art hot forging presses, in-house CNC machining, and rigorous QA systems (ISO 9001, ISO14001,ISO45001) to deliver high-strength, precision-forged components worldwide. Our turnkey approach—from die engineering to heat treatment and finishing—ensures minimal lead times and maximum peace of mind.

Ready to partner with a trusted OEM metal forging expert? Contact our team today to discuss your project requirements and receive a transparent, no-obligation quote. Let HULK Metal be the foundation of your next great product.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

April.30, 2025

A step-by-step guide to ordering forged steel products

READ MORE

-

April.18, 2025

Closed Die Steel Forgings Deliver Numerous Advantages

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE

-

January.23, 2025

The difference between forging and casting

READ MORE