By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

How to Choose the Right Forging Service for Your Industrial Project

Choosing the right forging service provider for your industrial project isn’t a decision to take lightly. Whether you’re sourcing forged components for heavy construction, mining equipment, transportation, or custom machinery, the partner you choose can affect everything from the performance of your parts to the reliability of your supply chain. Forging is more than just shaping metal under heat and pressure. It’s a precision-driven process that demands material knowledge, engineering skill, production efficiency, and quality control. So how do you ensure you’re selecting the right company to get the job done right? Let’s explore.

Understand What Your Project Really Needs

Before approaching any forging company, get your internal requirements clear. You’ll want to answer some practical questions first:

What type of part are you manufacturing?

What mechanical properties are essential (strength, toughness, fatigue resistance)?

What metal or alloy is best suited?

Are there specific tolerance or surface finish needs?

Is machining, heat treatment, or coating needed after forging?

What’s your lead time and production quantity?

These answers will determine whether you need open die, closed die, hot, or cold forging, and help you filter providers accordingly.

Match the Forging Process with Your Part Requirements

Different forging methods suit different applications. Here’s a quick breakdown:

Open Die Forging: Ideal for large, simple shapes like shafts, cylinders, and rings. Offers grain refinement and directional strength.

Closed Die Forging (Impression Die): Great for complex, high-volume parts with tight tolerances.

Hot Forging: Suitable for parts requiring high strength and toughness. Common inthe automotive and construction industries.

Cold Forging: Delivers excellent surface finish and dimensional accuracy. Best for small to mid-size components.

Knowing which method best fits your product ensures efficient production and fewer revisions later.

Evaluate Material Expertise and Capabilities

The material used in forging dramatically impacts performance. Reliable forging companies will:

Offer a wide range of steels and alloys (carbon, alloy, stainless, tool steels).

Help you select materials based on mechanical, thermal, and corrosion requirements.

Understand how different metals respond to forging pressures and temperatures.

At HULK Metal, our engineers work closely with clients to recommend optimal material grades based on intended use and cost targets. We maintain stable partnerships with high-quality raw material suppliers to ensure consistent quality and traceability. Furthermore, our in-depth understanding of metallurgical behavior allows us to advise clients on cost-effective alternatives without compromising part integrity.

Review Production Facilities and Equipment

A company’s equipment tells you what they can and can’t deliver. Top-tier forging services should have:

High-tonnage hydraulic presses and hammer systems.

CNC machining centers for post-forge processing.

Heat treatment furnaces with temperature control systems.

On-site die manufacturing for closed die forging.

These facilities reflect not only production capacity but also the precision and repeatability they can achieve.

HULK Metal has die forging production lines based on 1000T hot die forging press, 400T hot die forging press, 630T hot die forging press, and 200T hot die forging press. From mold design to final machining, each step is managed in-house to ensure speed and quality control. Our multiple forging lines allow us to handle orders from a few hundred pieces to mass production runs. We also invest continuously in upgrading our equipment and adopting lean production strategies to enhance operational efficiency.

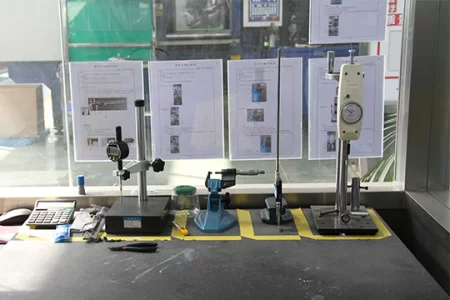

Inspect Quality Control Systems

You can’t compromise on quality in critical components. A good forging partner will:

Hold certifications like ISO 9001.

Maintain in-house labs for mechanical testing (tensile, hardness, impact).

Conduct dimensional inspections, NDT, and microstructure analysis.

Provide full documentation and traceability.

HULK Metal combines stringent in-process checks with end-of-line verification, ensuring consistency from the first piece to the last. We also support third-party inspections such as SGS, TUV, and BV when required by the client. Our dedicated quality assurance team ensures each step of production complies with strict tolerances, delivering parts that meet international standards.

Ask About Flexibility and Lead Times

Not every project runs on the same schedule. A capable forging supplier should offer:

Fast response for quotes and technical questions.

Prototypes and small batch production options.

Scalable capacity to handle increased demand.

Reliable delivery timeframes, even under tight schedules.

At HULK Metal, our global supply chain network and flexible manufacturing allow us to respond quickly to customer needs without compromising on quality. We maintain inventory buffers and production redundancies to ensure continuity in urgent projects. Our streamlined workflow—from technical review to dispatch—allows us to compress production timelines and meet critical delivery schedules.

Consider Value-Added Services

The best forging providers offer more than just forged blanks. Look for a company that provides:

Heat treatment (quenching, tempering, normalizing, annealing).

Surface finishing (blasting, galvanizing, painting).

CNC machining and threading.

Packaging, labeling, and export logistics.

HULK Metal offers a one-stop forging solution—from mold development and forging to precision machining and final packaging. Our team coordinates every detail to reduce your workload and speed up your supply chain. We can also assist with assembly, testing, and kitting services to streamline your internal production or fulfillment process.

Request Samples or Case Studies

Reputable companies should be able to show:

Past work for similar industries or part types.

Customer testimonials or references.

Sample parts to demonstrate finishing and tolerance standards.

This gives you a sense of their real-world capabilities beyond marketing brochures.

HULK Metal has successfully served global clients across the construction, mining, energy, and transportation sectors. We regularly provide case studies and engineering support during quotation to demonstrate our approach and capabilities. Many clients have stayed with us for over a decade thanks to our dependable delivery, transparency, and engineering insight.

Evaluate Communication and Support

Communication is key to successful partnerships. Strong forging companies:

Offer multilingual sales and technical teams.

Provide regular production updates.

Respond promptly to issues or design changes.

Work with clients through every stage—from RFQ to delivery.

At HULK Metal, our dedicated international service team works across time zones to provide responsive support. From quotation to post-delivery assistance, we’re committed to transparency and technical clarity. We value long-term partnerships, and our account managers take a proactive approach to ensure that our solutions evolve with your needs.

Think in Terms of Long-Term Value, Not Just Price

Yes, price matters—but so does the total value offered. When comparing quotes, consider:

Are material and testing costs included?

How does the supplier handle issues or defects?

Will lower upfront cost lead to more downstream problems?

Does the company support you post-delivery?

Choosing a supplier who gets it right the first time often saves time, money, and headaches in the long run.

HULK Metal focuses on delivering high-value forging services with competitive pricing and superior service. Our long-term clients trust us for quality stability, engineering collaboration, and dependable after-sales support. With our full-service capabilities and customer-centric approach, we offer more than parts—we offer peace of mind.

Selecting a forging service is more than just finding someone who can heat and hammer metal. It’s about choosing a reliable manufacturing partner who understands your goals, delivers consistent quality, and helps bring your design to life.

HULK Metal offers full-service forging solutions with advanced equipment, expert engineers, and comprehensive quality control. From material selection to final shipment, we provide tailored solutions that ensure your parts perform as expected—every time.

We welcome the opportunity to become your trusted forging partner.

Article Navigation

Article Navigation

Industries

Foundries

-

December.11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

February.28, 2025

Open Die Forging: Exploring the forging process and the key factors in selecting a OEM

READ MORE

-

February.24, 2025

Key Considerations for Closed Die Forging

READ MORE

-

February.18, 2025

Factors to consider when purchasing custom forgings

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE