By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

HULK Metal Wire Grips Production Process: From Raw Steel to Precision-Engineered Strength

In the world of lifting, rigging, and construction, wire grips may seem like small components — but they carry massive responsibility. These forged steel grips secure cables, wires, and rods under heavy loads, ensuring that every lifting operation remains safe, stable, and efficient.

At HULK Metal, we know that safety begins with precision. Every wire grip we produce is engineered to deliver maximum strength, superior durability, and consistent performance — even in the toughest working environments.

In this article, we’ll walk you through how HULK Metal manufactures wire grips from start to finish — from premium steel selection to precision CNC machining — and show how each step reflects our commitment to excellence, reliability, and customer trust.

Selecting Premium Materials: The Foundation of Quality

High-Strength Alloy Steel for Maximum Safety

Every great product starts with the right material. We use high-strength alloy or carbon steel with excellent tensile properties and toughness. These materials can withstand extreme stress, impact, and fatigue without losing shape or strength.

Rigorous Pre-Production Testing

Before a single piece of steel enters production, it undergoes chemical composition analysis and mechanical testing — including hardness, yield strength, and tensile strength checks. This ensures that every batch of material meets the strict requirements of ASTM and ISO standards, guaranteeing long-lasting performance and safety.

Because we believe: only the best materials can create the most reliable wire grips.

Steel Cutting: Precision Starts Here

Cutting for Accuracy and Efficiency

The steel bars are precisely cut into billets based on the product’s required weight and dimensions. Our automated cutting machines ensure tight tolerances and clean edges, setting the stage for a flawless forging process.

Why It Matters

Accurate cutting ensures:

Even heat distribution during forging

Stable material flow, minimizing structural defects

Reduced waste and higher production efficiency

At HULK Metal, precision is not a goal — it’s a habit we apply from the very first step.

Mold Preheating: Preparing the Tools for Perfection

Before forging begins, the molds (dies) are preheated to achieve optimal performance. Cold dies can cause cracks or uneven metal flow. Preheating ensures that the steel deforms smoothly, resulting in a flawless surface and longer die life.

Using induction and furnace preheating systems, we maintain a consistent temperature that maximizes material integrity and extends the life of our production tools. This step ensures that every forging stroke is precise and uniform.

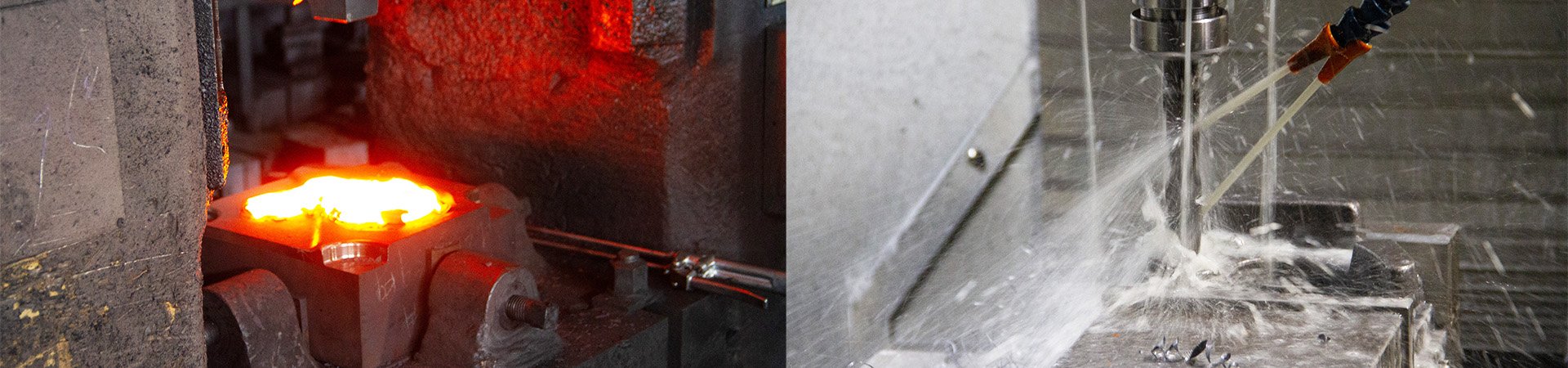

Open-Die Forging: Strength Begins to Take Shape

Controlled Power, Superior Structure

During open-die forging, heated steel billets are hammered between flat dies to form the initial shape of the wire grip. This process compresses the steel’s internal grain structure, enhancing its toughness, fatigue resistance, and density.

Benefits of Open-Die Forging

Strengthens the internal grain flow

Reduces porosity and internal voids

Improves shock and fatigue resistance

The result is a billet that’s not just shaped — but refined for strength from the inside out.

Closed-Die Forging: Precision Forming for Final Shape

The pre-shaped billet is then placed into closed dies, where intense pressure molds it into the final wire grip geometry. Every contour, curve, and cavity is formed with micrometric precision.

Why This Step Matters

Closed-die forging creates a dense, uniform structure that improves load-bearing capacity and eliminates weak points. It ensures that each wire grip meets exact dimensional specifications and can perform reliably under high-stress applications.

At HULK Metal, our forging presses and dies are precisely calibrated to produce consistent, repeatable results — ensuring every product meets the same high standard.

Trimming and Flash Removal: Clean and Perfect

What Is Flash?

When steel is forged, a small amount of excess metal, known as flash, squeezes out around the edges. This must be removed to achieve a clean, precise part.

The Finishing Process

Using CNC trimming machines and shearing tools, we remove all excess metal, ensuring smooth edges and a perfect outline. This not only enhances appearance but also prepares the product for machining and coating.

The Result

Reduced stress points

Enhanced structural integrity

Smoother surfaces for better coating and assembly

Every grip that leaves this stage is clean, symmetrical, and ready for fine machining.

CNC Machining: Where Precision Meets Perfection

Advanced Machining Technology

In the CNC machining stage, every detail comes to life. Using state-of-the-art turning, milling, and drilling centers, we machine the critical dimensions, holes, and threads with extreme accuracy.

Each part is processed under strict tolerances to ensure perfect fit and function.

Surface Treatment and Finishing

After machining:

Threads are cut to exact specifications for secure installation.

Surfaces are polished, coated, or galvanized to resist corrosion and wear.

Every dimension is automatically checked by digital measuring systems.

This ensures that every HULK Metal wire grip is not just functional — but flawlessly engineered for long-term performance.

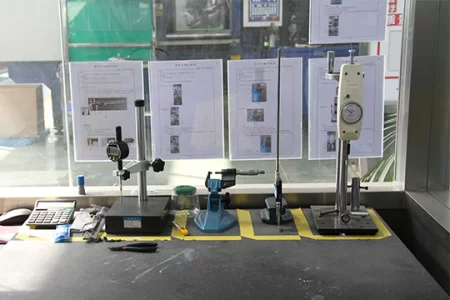

Comprehensive Quality Inspection: Safety You Can Trust

Multi-Layered Testing System

Every wire grip undergoes a multi-stage inspection process before shipment:

Visual and dimensional checks for accuracy

Hardness and tensile testing for mechanical performance

Ultrasonic and magnetic testing to detect internal flaws

Load testing to verify safe working limits

Our quality inspection laboratory is equipped with nearly 50 testing instruments, allowing full-spectrum verification of each product.

Certified Quality, Verified Safety

Every batch comes with a detailed inspection report, confirming compliance with international safety standards such as ASTM, EN, and ISO.

For us, quality isn’t just a checkbox — it’s a promise of safety and reliability that we stand behind.

Protective Packaging and On-Time Delivery

Smart Packaging for Global Shipping

Once approved, the wire grips are carefully packed to prevent corrosion and mechanical damage during transportation. A protective coating is often applied to maintain surface integrity.

Each product is sorted and labeled by model and size, ensuring smooth logistics and easy handling upon arrival.

Reliable Global Supply

Our logistics team coordinates efficient shipping solutions to ensure fast, safe, and traceable delivery. Whether by sea, air, or land, we make sure your products arrive ready for immediate use — in perfect condition.

Why Choose HULK Metal?

End-to-End Manufacturing

From steel selection to CNC machining, every process is completed in-house, allowing us to maintain total control over quality, consistency, and cost.

Advanced Equipment

We use modern forging presses, CNC centers, and automated testing systems to ensure every part meets exacting international standards.

Tailored Solutions

Need custom dimensions, finishes, or load capacities? Our engineering team provides flexible OEM and ODM support to meet your specific project needs.

Reliable Quality Assurance

Each product undergoes multiple inspections before delivery, supported by professional testing reports and traceable production data.

One-Stop Service

From design consultation to packaging and after-sales support, HULK Metal provides a complete, worry-free procurement experience.

Producing a reliable wire grip takes more than just steel and machines — it takes precision, discipline, and dedication. Every step, from raw material selection to final CNC finishing, defines the product’s strength, safety, and performance.

At HULK Metal, we take pride in manufacturing wire grips that meet the highest standards of engineering excellence and operational safety. Our continuous investment in advanced technology, professional talent, and strict quality control ensures that every product we deliver exceeds expectations.

Whether you’re working on a construction project, a marine lifting system, or an industrial application, HULK Metal wire grips provide the safety, reliability, and confidence you need.

Article Navigation

Article Navigation

Foundries

-

December.11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

September.14, 2024

Types of Jaw Wire Grip and Suitable Use Scenarios

READ MORE

-

September.12, 2024

Do you know the comprehensive analysis of wire grip puller?

READ MORE

-

February.28, 2025

Open Die Forging: Exploring the forging process and the key factors in selecting a OEM

READ MORE

-

February.24, 2025

Parallel Jaw Grip: An important tool for improving work efficiency and safety

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE

-

December.27, 2024

What are the models of wire grip and their different usage scenarios?

READ MORE