By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Reduce Your Production Costs with the Right OEM Forging Parts Supplier

In today's industrial environment, OEM forgings are widely used in automotive, construction machinery, mining equipment, agricultural systems, and industrial sectors. These components typically bear heavy loads and operate under harsh conditions.

For engineers and purchasing managers, a key question always remains:

How can production costs be reduced without compromising strength, dimensional accuracy, or corrosion resistance?

True cost optimization is not about blindly lowering prices, but about improving efficiency at every stage of production. Companies like HULK Metal achieve this through systematic engineering, lean manufacturing, and an integrated supply chain.

The following explains how this approach creates real value for customers.

Intelligent Raw Material Management

Raw materials typically account for a large portion of the total cost of forgings. Proper management of raw materials can immediately deliver cost advantages.

Long-Term Material Partnerships

HULK Metal works closely with trusted steel mills and material suppliers. Long-term partnerships offer:

More stable pricing

Reliable material supply

Consistent chemical composition

Market volatility risk prediction

This ensures clients receive consistent quality while avoiding sudden cost increases due to raw material price fluctuations. In the event of impending raw material price increases, HULK Metal helps them make timely procurement decisions and better manage project budgets.

Material Grade Optimization

Choosing the appropriate material grade is crucial. Using a grade higher than required increases costs without adding value.

Our engineering team assesses:

Load conditions

Required strength

Fatigue resistance

Corrosive environment

Then, we recommend the most suitable grade for carbon steel, alloy steel, stainless steel, aluminum, or iron. This avoids over-selection of materials and reduces material and processing costs.

Improved Material Utilization

Modern forging aims to reduce waste. Through optimized die design and near-net-shape forging, HULK Metal minimizes machining allowances.

Advantages include:

Reduced raw material usage

Reduced energy consumption during heating

Shorter processing time

Increased production efficiency

Even a slight increase in material utilization can result in significant cost savings in high-volume OEM projects.

Waste-Free Process Engineering

The difference between a typical supplier and a true manufacturing partner lies in engineering capabilities.

Advanced Forging Simulation

Before production begins, HULK Metal uses simulation software to analyze metal flow and stress distribution. This allows us to:

Identify potential defects early

Optimize die structure

Reduce trial production times

Shorten development time

By solving problems digitally rather than physically, we reduce costs and shorten delivery cycles.

Precision Die Design

Forging dies directly impact product costs. Inferior dies wear out quickly and lead to dimensional instability.

Our in-house die design team ensures:

Extended die life

Reduced maintenance frequency

Stable part dimensions

Reduced unit cost

Longer die life means more stable production and fewer interruptions.

Controlled Heating and Deformation

Temperature control is crucial during hot forging. Overheating wastes energy and causes oxidation. Undercooling can lead to cracking.

HULK Metal rigorously controls:

Heating temperature

Holding time

Deformation speed

This ensures a robust grain structure, stable mechanical properties, and optimized energy consumption.

Improved Production Efficiency

Efficient production reduces waste and lowers overall costs.

Automation and Modernized Equipment

HULK Metal operates forging presses ranging from 200 to 1000 tons, capable of producing parts from 0.5 kg to 50 kg.

Automation and precision equipment facilitate:

Stable production cycles

Lower human error rates

Consistent product quality

Faster order fulfillment

Our production team members have an average of over 10 years of experience, combining automation technology with practical experience.

Lean Manufacturing

Lean manufacturing aims to eliminate unnecessary steps in the production process.

From order confirmation to final delivery, we optimize our operational processes to:

Reduce waiting time

Improve workflow efficiency

Shorten delivery cycles

This ultimately results in faster turnaround times while ensuring product quality.

High equipment utilization

Large forging presses represent a significant investment. Efficient production planning ensures high equipment utilization, thus spreading fixed costs across higher output.

Better capacity management means customers can obtain more competitive prices.

Quality Control as a Cost-Saving Tool

Some companies view quality control as an expense. However, in reality, poor quality is the real cost.

Furthermore, it can lead to higher costs.

Preventative Quality Management

HULK Metal doesn't wait until the last minute to discover problems; instead, it prevents defects at the source.

This approach reduces:

Scrap rates

Rework costs

Delivery delays

Customer complaints

Prevention is always cheaper than remediation.

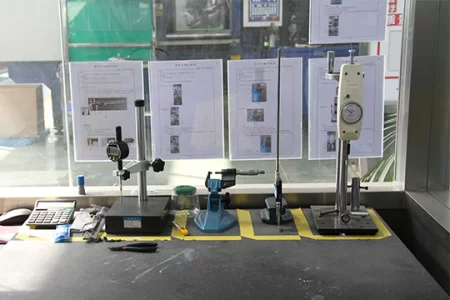

Advanced Testing Equipment

Our quality control center is equipped with:

Coordinate Measuring Machine (CMM) for dimensional inspection

Spectrometer for material verification

Ultrasonic flaw detector and flaw detection equipment for internal defect detection

Tensile testing machine and hardness testing machine for mechanical property verification

Salt spray tester for corrosion resistance testing

This comprehensive testing system ensures that every batch of products meets customer specifications and international standards.

Reduced Defect Rate

Our experienced quality control engineers—many with over 20 years of industry experience—strictly monitor the production process. Lower defect rates directly reduce hidden costs and protect our customers' supply chains.

One-Stop Secondary Processing Services

Working with multiple suppliers increases hidden costs such as transportation, coordination, and communication errors.

HULK Metal offers the following integrated services:

Machining

Our in-house machining center ensures:

Precise tolerances

Reduced logistics costs

Faster delivery speeds

Heat Treatment

Proper heat treatment ensures appropriate hardness and strength. Controlled process flows prevent deformation and avoid unnecessary rework.

Surface Treatment

We coordinate appropriate surface treatment solutions to meet corrosion resistance and durability requirements without over-design.

One-stop solutions streamline the procurement process and reduce total cost of ownership.

Early Engineering Collaboration

The greatest cost savings often occur before production begins.

Design for Manufacturability (DFM)

By reviewing drawings early, our engineering team can suggest improvements such as:

Simplifying forging processes

Reducing machining time

Improving structural performance

Reducing material consumption

This proactive communication helps customers avoid costly design errors.

Optimizing Safety Factors

Over-designed parts consume excessive material. Under-designed parts are at risk of failure.

We help customers find the optimal balance between safety and cost by analyzing load requirements and operating conditions.

Sustainable Manufacturing Practices

Long-term cost control requires sustainable production methods.

HULK Metal's Continuous Improvement:

Energy-efficient heating systems

Scrap recycling processes

Safe packaging and warehousing systems

Reducing waste and improving logistical protection help lower indirect costs and increase delivery reliability.

Why Choose HULK Metal as Your OEM Forging Partner?

Cost optimization is not about cutting corners. The key lies in intelligent management of every aspect of production.

Qingdao HULK Metal Technology Co., Ltd. provides:

Integrated supply chain management

Strong engineering and mold design capabilities

Forging capacity from 200 to 1000 tons

Comprehensive quality inspection system

One-stop machining and finishing services

Stable raw material supply

Professional after-sales support

In case of any quality or quantity issues, we will provide replacement or compensation solutions to protect customer interests.

Our experienced teams in procurement, technology, production, quality, logistics, and after-sales work together to ensure that every project achieves performance and cost targets.

Reducing costs while ensuring quality is not easy. This requires professional technology, rigorous management, and a reliable supply chain.

HULK Metal combines advanced engineering, efficient production systems, and rigorous quality control to provide OEM forged parts with the best overall value, not just the lowest price.

If you are looking for a reliable OEM forging supplier capable of providing high-quality parts at the best cost, our team is ready to support your project.

Contact HULK Metal today to discuss your drawings and requirements. Let us help you achieve both performance and cost-effectiveness.

Article Navigation

Article Navigation

Industries

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

March.07, 2025

What to look for when looking for a Forging Manufacturer?

READ MORE

-

February.28, 2025

Open Die Forging: Exploring the forging process and the key factors in selecting a OEM

READ MORE

-

February.18, 2025

Factors to consider when purchasing custom forgings

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE