By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

How Hot Forging with CNC Machining Improves Durability, Accuracy, and Efficiency?

In manufacturing, strength and precision are often inextricably linked. Hot forging ensures metal durability and structural integrity, while CNC machining guarantees precise part dimensions. HULK Metal has integrated these two processes into a single hot forging manufacturer with CNC machining capabilities that is trusted by customers worldwide.

This combination saves time, reduces costs, and increases production efficiency. Instead of sending parts to different suppliers for forging and machining, customers can complete all work in one place. This results in faster delivery, consistent quality, and components that are ready to use right out of the box.

What Are Our Advantages?

HULK Metal is more than just a forging shop. We are a full-service manufacturing partner, helping customers transform drawings into finished products. Our team has years of experience producing high-strength hot-forged metal parts for industries such as construction, mining, automotive, and energy.

Our Advantages:

One-Stop Manufacturing—We handle every step: raw material sourcing, hot forging, CNC machining, surface treatment, packaging, and logistics. Certified Quality – We adhere to ISO 9001 and other international quality standards to ensure reliability.

Professional Team – From engineers and machinists to quality inspectors and logistics experts, our staff is professionally trained to deliver efficient results.

We understand that every project has unique requirements, so we customize solutions to meet your technical requirements and timelines.

Our Hot Forging Process

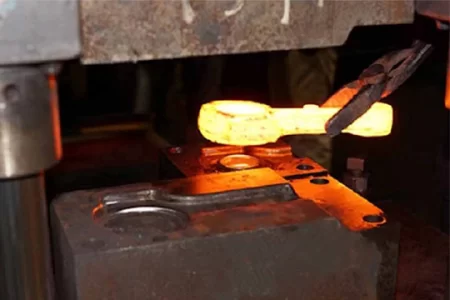

Hot forging involves heating metal to extremely high temperatures (typically between 900°C and 1,200°C) while shaping it. This makes the metal more flexible, allowing us to create parts with a better grain structure and higher strength.

Materials We Use:

Carbon Steel – Its high strength and toughness allow it to withstand heavy loads, making it an ideal material for various structural and mechanical components.

Alloy Steel – Its high strength combined with wear and impact resistance makes it ideal for demanding environments like mining and engineering.

Stainless Steel – Its excellent corrosion resistance ensures long-term rust resistance and stable performance, even in harsh conditions like marine and chemical industries.

Our Forging Equipment:

Open Die Forging – Offers a large processing area and high plasticity, making it ideal for producing large, non-standard, custom parts requiring maximum strength.

Closed Die Forging – Offers high die precision, suitable for high-volume metal part manufacturing with complex shapes and demanding dimensional consistency.

Presses and Hammers – With a tonnage range of 200 to 1,000 tons, they can efficiently and flexibly process workpieces of varying sizes and shapes.

Temperature Control – Precision heating using electromagnetic induction furnaces ensures uniform heating of the metal and maintains a stable temperature within the optimal forging range.

Whether it's small parts with precise dimensions and complex structures, or large, heavy components with high load-bearing capacity and substantial volume, HULK Metal can provide you with precision manufacturing through advanced forging processes and comprehensive quality control.

CNC Machining – The Precision Aspect of Production

Hot forging ensures the basic shape and strength of a part, while CNC machining ensures that every detail is precisely and accurately finished. Our CNC machining department uses advanced multi-axis equipment to produce complex and precise hot forgings.

Our Machining Capabilities:

3-, 4-, and 5-axis Milling – Utilizing multi-angle cutting to achieve complex surfaces and fine details, we meet the demands of producing complex shapes and demanding precision metal parts.

CNC Turning – Utilizing high-precision CNC equipment, we produce round parts, shafts, and precision threads, ensuring dimensional consistency and surface finish.

Drilling, Boring, and Tapping – Develop precise holes, increase hole diameters, and cut standard or special threads in metal workpieces to ensure assembly accuracy.

Grinding and Finishing – Utilizing precision grinding and post-processing, we achieve exceptionally smooth surfaces and stable dimensional tolerances, enhancing part durability and performance.

We perform real-time measurement and inspection during CNC machining of hot forgings, eliminating common issues like dimensional mismatches and improving overall efficiency.

From Design to Delivery – We Take Charge

One of the greatest advantages of working with HULK Metal is our comprehensive in-house service offering. We not only manufacture the parts, but also provide guidance from concept to finished product.

Our Process:

Design Support – Our engineers work with you to ensure your design is perfectly suited for forging and machining.

Tooling – We customize molds and tools to your specifications.

Hot Forging – Parts are formed under high pressure and high temperature.

CNC Machining – Parts are precision-machined to meet precise dimensional requirements.

Surface Treatment – Optional surface treatments include galvanizing, powder coating, and polishing.

Assembly and Packaging – We prepare components for immediate use.

Shipping and Logistics – We offer flexible delivery options for domestic and international orders.

Reliable Quality:

Material Testing – Only raw materials with proven quality are used to ensure they meet production requirements.

Dimensional Inspection – CMM coordinate measuring machines are used to ensure dimensional accuracy and consistency.

Non-destructive Testing – Ultrasonic and magnetic particle testing are used to detect internal or surface defects.

Performance Testing – Load and stress tests are conducted to ensure parts are safe and reliable.

Corrosion Resistance – Salt spray testing is performed on coated parts to verify corrosion resistance.

Industries We Serve

We work across many diverse industries, each with its own unique challenges and requirements.

Construction – Lifting anchors, connecting rings, and heavy-duty fasteners.

Mining – Wear-resistant parts that withstand extreme loads.

Automotive – Shafts, gears, and suspension components.

Energy – Wind turbines, oil rigs, and power plant hardware.

Marine – Corrosion-resistant accessories for ships and offshore platforms.

Real-World Success Stories

Over the years, we have completed countless projects for clients around the world. Here are some examples:

Mining equipment parts – Forged from alloy steel for longer service life.

Construction hardware – Produced to strict international safety standards.

Automotive components – High-precision shafts and gears for improved performance.

These projects demonstrate how combining hot forging with CNC machining produces parts that last longer, perform better, and fit more perfectly.

Why Choose HULK Metal

Choosing the right supplier involves more than just price. Here's why our customers keep coming back:

Integrated Service – You don't have to worry about coordinating between multiple suppliers.

Shorter Delivery Times – Forging and machining are performed in the same facility, eliminating the need for transit.

Customized Solutions – Designed to meet your exact needs, we offer a unique, customized solution.

Global Delivery – We've served customers in hundreds of countries and have experience shipping to customers worldwide.

Strong After-Sales Support – Your order doesn't end once your shipment arrives; our after-sales support is always there.

If you're looking for a partner who combines the strength of hot forging with the precision of CNC machining, HULK Metal is here to help. Our team, equipment, and processes are designed to deliver high-quality parts on time and on budget.

Whether you need high-volume production or a single custom component, we have you covered. Contact us today to discuss your project and learn how a hot forging manufacturer with CNC machining capabilities can make your products stronger, more precise, and more reliable.

Article Navigation

Article Navigation

Foundries

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

January.18, 2024

Forging: What Is It? What Are The Different Types of Hot Forging?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE