By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

How to Choose the Right Surface Treatment for Forged Components?

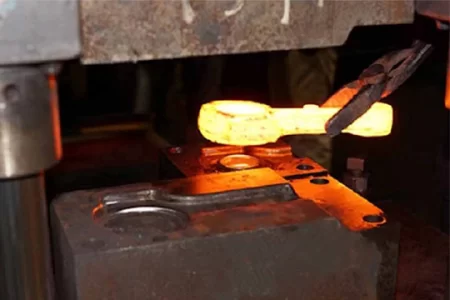

Hot forging is one of the most widely used metal forming processes in modern manufacturing due to its ability to produce components with high density, excellent mechanical properties, and superior material utilization. By deforming metals at elevated temperatures, hot forging refines the internal grain structure, resulting in parts that combine strength, ductility, and impact resistance.

However, despite these internal advantages, the surface condition of hot-forged parts often becomes a limiting factor in overall performance. During the high-temperature forming process, the metal surface is exposed to oxygen and reactive gases, leading to the formation of oxide scales, decarburization layers, and micro-cracks. These defects can severely compromise corrosion resistance, fatigue life, and subsequent machining or coating quality.

Therefore, scientific and targeted surface treatment is not just a cosmetic step—it is a critical stage in releasing the full performance potential of forged components.

Common Surface Issues in Hot Forged Parts

Oxide Scale (Mill Scale)

During hot forging, metal surfaces react with oxygen in the atmosphere to form oxide layers. This mill scale often consists of multiple iron oxides (FeO, Fe₂O₃, Fe₃O₄) that adhere tightly to the surface. If not removed, these brittle layers can flake off during machining, causing surface irregularities, coating adhesion failure, and even premature corrosion in service environments.

Surface Decarburization

At high forging temperatures, carbon from the steel surface diffuses outward and reacts with oxygen or water vapor to form CO or CO₂ gas, resulting in a decarburized layer. This layer reduces surface hardness, wear resistance, and fatigue strength, particularly in carbon and alloy steels used for gears, shafts, and fasteners.

Micro-Cracks and Folds (Laps/Folds)

Improper die design or uneven material flow can cause laps, folds, or fine cracks during forging. These discontinuities may remain hidden beneath oxide scales but can propagate under cyclic stress, ultimately leading to fatigue failure or leakage in pressure components.

Dimensional Tolerance and Surface Roughness

Forging inherently produces a relatively rough surface. If left untreated, it may limit precision machining, affect coating adhesion, or compromise dimensional accuracy. Therefore, post-forging surface processing becomes essential to meet engineering and aesthetic standards.

Key Surface Treatment Methods

Mechanical Cleaning

Shot Blasting / Grit Blasting

This is the most common mechanical cleaning method for forged parts. Abrasive media such as steel shots or grits are propelled at high velocity to remove oxide scales and contaminants, leaving a clean, roughened surface. In addition to cleaning, blasting introduces compressive residual stresses, enhancing fatigue strength—ideal for components like connecting rods and crankshafts.

Peening

Peening uses controlled impact energy to plastically deform the surface, closing micro-cracks and improving surface integrity. It enhances fatigue life and stress corrosion resistance, particularly in automotive and aerospace applications.

Brushing / Tumbling

These finishing techniques employ brushes or tumbling media to achieve smooth, uniform surfaces, often used for decorative components or parts requiring tight dimensional tolerances before coating or plating.

Chemical and Electrochemical Treatments

Pickling

Pickling uses acid solutions (commonly HCl, H₂SO₄, or mixed acids) to chemically remove oxide scales and rust. It is highly efficient but must be carefully controlled to prevent over-etching or hydrogen embrittlement, which can weaken high-strength steels.

Phosphating

Phosphate conversion coatings provide an excellent base layer for painting or powder coating, improving adhesion and corrosion resistance. This method is widely used for automotive brackets, fasteners, and hydraulic fittings.

Anodizing (for Aluminum Alloys)

Anodizing thickens the natural oxide layer on aluminum, providing enhanced corrosion and wear resistance. It can also improve paint adhesion and aesthetic appearance, commonly used in aerospace and electronics industries.

Heat Treatment–Based Surface Enhancement

Controlled Normalizing and Annealing

Post-forging heat treatments refine grain structure and relieve internal stresses. By controlling the cooling rate and atmosphere, surface oxidation and decarburization can be minimized, ensuring consistent mechanical performance.

Carburizing / Nitriding

For components subjected to wear or high contact stress, case hardening techniques like carburizing and nitriding are ideal.

Carburizing enriches the surface with carbon, forming a hard martensitic case after quenching, suitable for gears, shafts, and cams.

Nitriding introduces nitrogen into the surface, forming hard nitrides that enhance wear and corrosion resistance without requiring quenching, minimizing distortion.

Coatings and Plating Technologies

Electroplating (Zinc, Nickel, or Zinc-Nickel Alloys)

Electroplated coatings provide a sacrificial corrosion barrier, protecting the underlying steel from oxidation. Zinc-nickel plating offers superior corrosion resistance and heat stability, ideal for automotive and marine components.

Dacromet Coating

Dacromet, a water-based zinc-aluminum flake coating, provides excellent anti-corrosion performance with low environmental impact. It’s often used in fasteners, clamps, and construction hardware.

Hot-Dip Galvanizing

In this process, forged parts are dipped into molten zinc, forming a thick, durable coating that can protect steel for decades in harsh outdoor or marine environments.

PVD / CVD Coatings

Physical and chemical vapor deposition methods deposit ultra-hard coatings (TiN, CrN, DLC) that significantly enhance wear resistance, hardness, and thermal stability, making them suitable for cutting tools, molds, and aerospace components.

How to Choose the Right Surface Treatment Scheme

Selecting the optimal surface treatment requires a holistic understanding of the part’s function, material, and environment.

Key Considerations:

Service Environment: Corrosive exposure, temperature, and mechanical load define the required protection level.

Material Type: Carbon steels benefit from carburizing or galvanizing; stainless steels may require passivation or electropolishing; aluminum alloys suit anodizing.

Post-Processing Needs: Coating compatibility with welding, painting, or machining must be ensured.

Cost and Production Volume: High-performance coatings like PVD are ideal for precision tools, while cost-effective galvanizing suits mass production.

A structured decision process—starting from functional requirements → environmental conditions → cost feasibility—ensures both performance and efficiency in industrial applications.

HULK Metal’s Integrated Approach

At HULK Metal, surface treatment is seamlessly integrated into a complete production ecosystem—from forging, heat treatment, and surface processing to final inspection and packaging.

One-Stop Supply Chain Advantage

Our vertical integration ensures consistent quality and full traceability throughout every production stage. Whether you need small-batch precision components or large-scale industrial forgings, HULK Metal provides reliable, repeatable results.

Customized Technical Solutions

We tailor surface treatment processes based on customer drawings or 3D models. Each project is carefully evaluated to match the most efficient, cost-effective surface solution—from blasting and pickling to advanced plating or coating.

Quality Assurance System

Equipped with spectrometers, salt spray testers, and surface roughness instruments, HULK Metal verifies every treated surface to ensure compliance with international standards. Our rigorous inspection process guarantees that every component meets its intended mechanical, visual, and durability requirements.

B2B-Focused Service

We specialize in industrial-scale production, supporting OEM and engineering customers with flexible scheduling, packaging, and logistics options to meet global supply chain demands.

Surface treatment is not an optional afterthought—it is the final and essential link in the performance chain of hot-forged components. Properly treated surfaces not only enhance corrosion and wear resistance but also extend service life, improve aesthetics, and reduce maintenance costs.

By integrating material science, process engineering, and quality control, HULK Metal helps manufacturers fully unlock the potential of their forged products.

Ready to enhance your forged components?

Contact the HULK Metal technical team today to receive a free surface treatment consultation tailored to your project requirements. Together, we’ll ensure your parts perform flawlessly—from the inside out.

Article Navigation

Article Navigation

Industries

Foundries

-

September.12, 2024

Do you know the comprehensive analysis of wire grip puller?

READ MORE

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

June.09, 2025

How to Find an OEM Metal Forging Factory?

READ MORE

-

November.29, 2024

What is steel forging?

READ MORE

-

July.30, 2024

What are the materials for hot forging?

READ MORE

-

July.03, 2024

What are the processes of hot forging?

READ MORE