By sharing knowledge, experience and views in the field of forging technology, we help you understand, learn and apply relevant technologies.

Hulk Metal Forging Technology

Share technical experience

-

Home>

-

Blog>

-

Technology>

Choosing the Right Hot Forging Material: Carbon Steel, Alloy Steel, or Stainless Steel

In modern industrial manufacturing, hot forging plays a vital role in producing high-strength, durable, and cost-effective components. By heating metal above its recrystallization temperature and then forming it under pressure, hot forging improves the material's grain structure and mechanical properties. This process ensures superior toughness and fatigue resistance compared to other manufacturing techniques.

One of the most important factors in hot forging is material selection. Different materials behave differently under high temperatures and mechanical stress, which directly impacts their performance, cost, and application suitability. The most widely used materials for hot forging include carbon steel, alloy steel, and stainless steel. Each material offers unique advantages and trade-offs, making it suitable for specific industries and work environments.

This article provides a detailed comparison of hot forging of carbon steel, alloy steel, and stainless steel, focusing on their material properties, forging advantages, limitations, applications, and cost considerations. Finally, you'll learn how to select the right forging material for your project and why partnering with a reliable manufacturer like HULK Metal is key to success.

Hot Forging of Carbon Steel

Key Material Characteristics

Carbon steel is one of the most commonly used materials in the forging industry. It is primarily composed of iron and carbon, with the carbon content typically ranging from 0.05% to 2.1%. Carbon steel can be categorized as low-carbon, medium-carbon, and high-carbon steel based on its carbon content, each offering a balance of hardness, ductility, and tensile strength.

Low-carbon steel (mild steel): Excellent ductility and weldability, but lower strength.

Medium-carbon steel: Balanced hardness and toughness, suitable for automotive parts.

High-carbon steel: High hardness and good wear resistance, but lower ductility.

Advantages of Forging

Carbon steel is widely used in hot forging due to its excellent forgeability. The material responds well to heating and forming, making mass production cost-effective. Key advantages include:

Cost-effectiveness: Carbon steel is less expensive than alloy steel and stainless steel.

Widely available: A stable supply chain ensures consistent sourcing.

Improving mechanical properties through heat treatment: Processes such as quenching and tempering increase strength and hardness. 2.3 Limitations

Low Corrosion Resistance: Without protective coatings or treatments, carbon steel parts are susceptible to rust.

Moderate Performance at High Temperatures: Carbon steel loses strength more rapidly when heated than alloy steel or stainless steel.

Moderate Performance at High Temperatures: Carbon steel loses strength more rapidly when heated than alloy steel or stainless steel.

Typical Applications

Hot forging of carbon steel is widely used due to its cost advantages and balanced mechanical properties:

Automotive parts, such as gears, crankshafts, and shafts

Building hardware, including fasteners and brackets

General machinery and agricultural equipment

Hand tools and industrial hardware

Hot Forging of Alloy Steel

Key Material Properties

Alloy steel is made by adding elements such as chromium (Cr), molybdenum (Mo), nickel (Ni), and vanadium (V) to carbon steel. These alloying elements significantly enhance mechanical properties, making alloy steels stronger, more ductile, and more resistant to wear and fatigue. ·

Chromium: Improves hardness and corrosion resistance.

Molybdenum: Improves high-temperature strength.

Nickel: Improves toughness.

Vanadium: Improves wear resistance and fatigue strength.

Advantages of Forging

Hot-forged alloy steels outperform carbon steels. Key advantages include:

·

High strength and toughness: Suitable for heavy-duty applications.

Increased fatigue resistance: Critical for components that rotate or experience shock loads.

Wear resistance: Extends the service life of friction components.

Increased heat resistance: Outperforms carbon steel at high temperatures.

Limitations

Higher cost: Adding alloying elements increases production costs.

More stringent processing requirements: Alloy steels require precise heating, forging, and heat treatment to avoid defects. 3.4 Typical Applications

Hot forging of alloy steels is commonly used in industries requiring high-performance and long-life components:

Automotive components, including axles, connecting rods, and transmissions

Energy industry components (oil and gas, wind turbines)

Mining and heavy machinery components are subject to high loads

Hot Forging of Stainless Steels

Key Material Properties

Stainless steels contain at least 10.5% chromium, which forms a passive oxide layer on the surface, providing excellent corrosion resistance. Some grades also contain nickel and molybdenum, further enhancing toughness and resistance to harsh environments.

The most common hot-forged stainless steel grades include:

Austenitic stainless steels (e.g., 304, 316): Excellent corrosion resistance and toughness.

Martensitic stainless steels (e.g., 410, 420): High hardness and strength.

Duplex stainless steels: Balanced strength and corrosion resistance. 4.2 Advantages of Forging

Hot forging stainless steel is more challenging than hot forging carbon or alloy steels, but it offers unparalleled advantages:

Excellent corrosion resistance: Ideal for the marine, chemical, and medical industries.

High strength at elevated temperatures: Performs well in extreme environments.

Hygienic and clean surface finish: Suitable for food processing and medical equipment.

Limitations

Higher cost: Stainless steel is the most expensive of the three materials.

Forging is more demanding: Precise temperature control is required to prevent defects such as cracking or grain growth. 4.4 Typical Applications Hot-forged stainless steel parts are widely used in industries requiring stringent corrosion resistance and cleanliness requirements:

Chemical equipment and valves

Marine hardware exposed to seawater environments

Food and beverage processing machinery

Medical devices and equipment

Energy industry components are exposed to high temperatures and corrosive gases

Direct Comparison: Carbon Steel, Alloy Steel, and Stainless Steel

Mechanical Properties

Carbon Steel: Offers a combination of strength, ductility, and toughness, but its performance is limited in extreme environments.

Alloy Steel: Due to the addition of alloying elements, it has higher strength, toughness, and fatigue resistance.

Stainless Steel: Combines good strength with excellent corrosion resistance, making it suitable for harsh environments.

Corrosion Resistance

Carbon Steel: Requires protective coating or surface treatment.

Alloy Steel: Outperforms carbon steel, but still requires coating in corrosive environments.

Stainless Steel: Inherently corrosion-resistant, even in marine or chemical applications. 5.3 Cost and Processing Difficulty

Carbon Steel: Lowest cost and easiest to forge.

Alloy Steel: Higher price, requiring advanced forging and heat treatment controls.

Stainless Steel: Highest cost and most challenging to forge due to stringent temperature requirements.

Applications

Carbon Steel: Suitable for cost-sensitive industries and general machinery.

Alloy Steel: Ideal for aerospace, automotive, and heavy machinery requiring superior performance.

Stainless Steel: Suitable for industries requiring stringent hygiene and corrosion resistance, such as food, medical, and marine.

Why Choose HULK Metal for Hot Forging?

Choosing the right material is only part of the equation when it comes to ensuring the success of your forged parts. Equally important is choosing a reliable manufacturing partner with the expertise, technology, and supply chain capabilities to deliver consistent results.

HULK Metal is a professional forging manufacturer with many years of experience in hot forging carbon steel, alloy steel, and stainless steel. Here's why customers worldwide trust us:

Comprehensive supply chain: From raw material sourcing to forging, machining, surface treatment, packaging, and logistics.

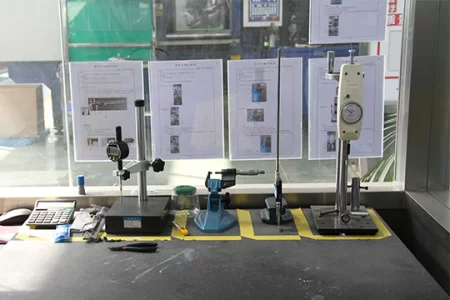

Advanced forging equipment: State-of-the-art hydraulic presses, induction heating systems, and precision machining equipment.

Strict quality control: ISO-certified production processes, 100% inspection, and international certifications (ISO, CE, TUV).

Customization capabilities: We design and produce forgings according to our customers' drawings, specifications, and performance requirements.

Reliable after-sales service: If any issues arise, we quickly respond with replacement, rework, or restocking.

Call to Action

When it comes to hot forging, material selection determines project success.

Carbon steel hot forgings offer a cost-effective solution for general applications.

Alloy steel hot forgings provide superior strength and durability for demanding industries.

Stainless steel hot forgings ensure long-term performance in corrosive and high-temperature environments. Each material offers unique advantages, and the right choice depends on your specific application, environment, and budget.

At HULK Metal, we specialize in helping our customers select the best materials and forging solutions. Whether you need high-volume automotive parts, heavy-duty alloy steel components, or corrosion-resistant stainless steel forgings, our team can provide you with precision and reliability.

Article Navigation

Article Navigation

Industries

Foundries

-

December.11, 2024

Analysis of the characteristics and main uses of wire grip for conductor

READ MORE

-

July.01, 2024

Difference between hot forging and cold forging

READ MORE

-

June.27, 2024

What are the advantages and disadvantages of the hot forging process?

READ MORE

-

February.28, 2025

Open Die Forging: Exploring the forging process and the key factors in selecting a OEM

READ MORE

-

February.24, 2025

Key Considerations for Closed Die Forging

READ MORE

-

February.18, 2025

Factors to consider when purchasing custom forgings

READ MORE

-

February.14, 2025

HULK Metal's hot forging quality control

READ MORE